Glycerin fructose canning machine for neurosurgery department

A neurosurgery and canning technology, which is applied in the field of neurosurgery glycerin fructose canning machines, can solve the problems of low canning efficiency and cumbersome procedures, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

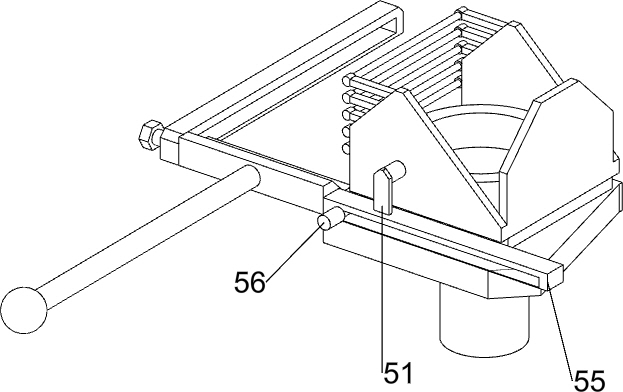

[0069] A glycerol fructose canning machine for neurosurgery, such as figure 1 As shown, it includes a bottom plate 1, a support plate 2, a canning mechanism 3 and a liquid replenishment mechanism 4, a canning mechanism 3 is arranged on the top right side of the bottom plate 1, a liquid replenishment mechanism 4 is arranged on the top right side of the bottom plate 1, and a liquid replenishment mechanism 4 is arranged on the top right side of the bottom plate 1. There is support plate 2.

[0070] When the glycerin fructose needs to be filled, the staff can place the can on the support plate 2, and then start the canning mechanism 3 to move downward, and the downward movement of the canning mechanism 3 drives the liquid replenishment mechanism 4 to move downward, thereby filling The canning mechanism 3 squeezes the glycerin fructose into the jar to complete the canning work, and the staff takes out the canned jar for the next step of processing.

Embodiment 2

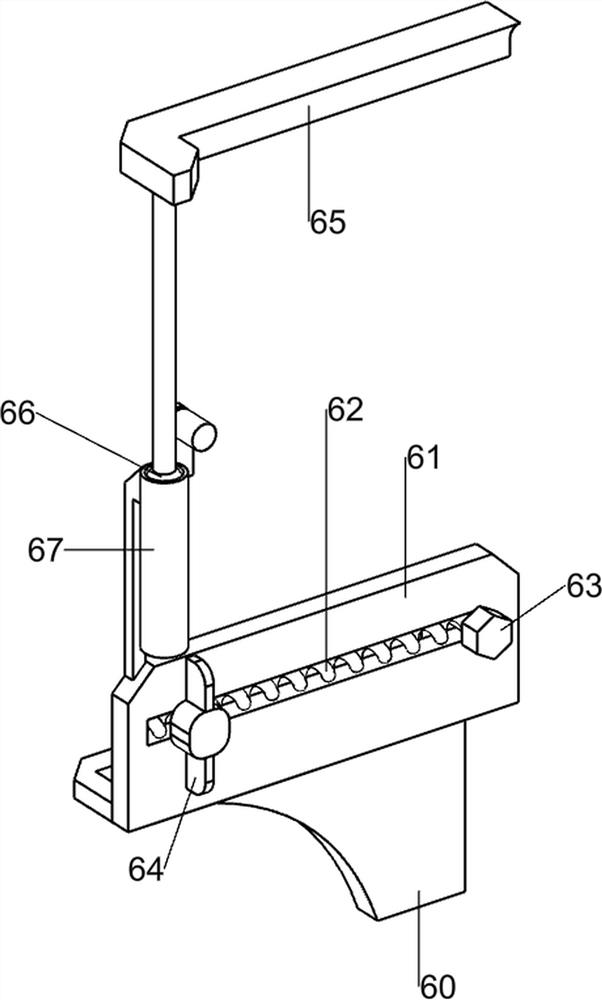

[0072] On the basis of Example 1, such as Figure 2-Figure 3 As shown, the canning mechanism 3 includes an L-shaped rod 30, a cylinder 31, a piston 32, a hollow cylinder 33 and a rubber plug 34. The right side of the bottom plate 1 is provided with an L-shaped rod 30, and the upper left end of the L-shaped rod 30 is provided with a cylinder. 31, the end of the cylinder 31 is provided with a piston 32, the liquid replenishing mechanism 4 is provided with a hollow cylinder 33, the piston 32 is located in the hollow cylinder 33 and cooperates with the hollow cylinder 33 in a sliding manner, and the lower part of the hollow cylinder 33 is surrounded by rubber plugs 34.

[0073] The liquid supplement mechanism 4 includes a bracket 40, a first slide rail 41, a liquid box 42, a feeding tube 43 and a first elastic member 44. Two brackets 40 are arranged on the top of the bottom plate 1, and the top of the bracket 40 is provided with a first slide rail. 41, a liquid box 42 is slidably ...

Embodiment 3

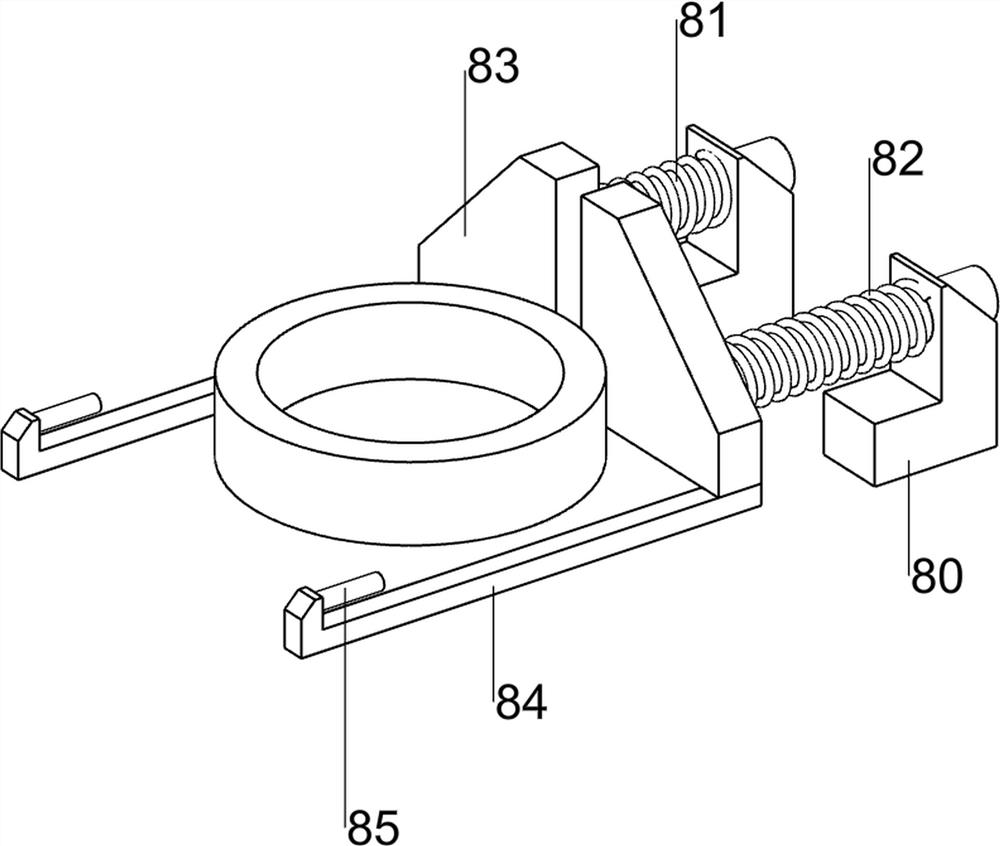

[0076] On the basis of Example 2, such as Figure 4-Figure 5 As shown, a charging mechanism 5 is also included, and the charging mechanism 5 includes a pillar 50, a pole 51, a second slide rail 52, a pushing plate 53, a material box 54, a guide rod 55 and a pushing plate 56, and the bottom plate 1 top The rear side is provided with a pillar 50, the rear side of the support plate 2 is provided with a guide rod 55, the top of the guide rod 55 is provided with a support rod 51, the support rod 51 is provided with a material box 54, and the guide rod 55 is slidably connected with a pusher plate 56, The pusher plate 56 is located at the bottom of the material box 54 , and the right side of the top of the support plate 2 is provided with a second slide rail 52 , and a pusher plate 53 is slidably connected to the second slide rail 52 .

[0077] The staff can put a certain amount of jars into the feed box 54, and then push the push plate 56 to move to the right, thereby driving the ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com