Acrylate resin for long-chain alkyl isocyanate modified ink and preparation method of acrylate resin

A technology of long-chain alkyl isocyanate and acrylate, applied in the field of polymer materials and preparation, can solve problems such as decreased treatment effect, achieve good adhesion ability, save preparation cost, and improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

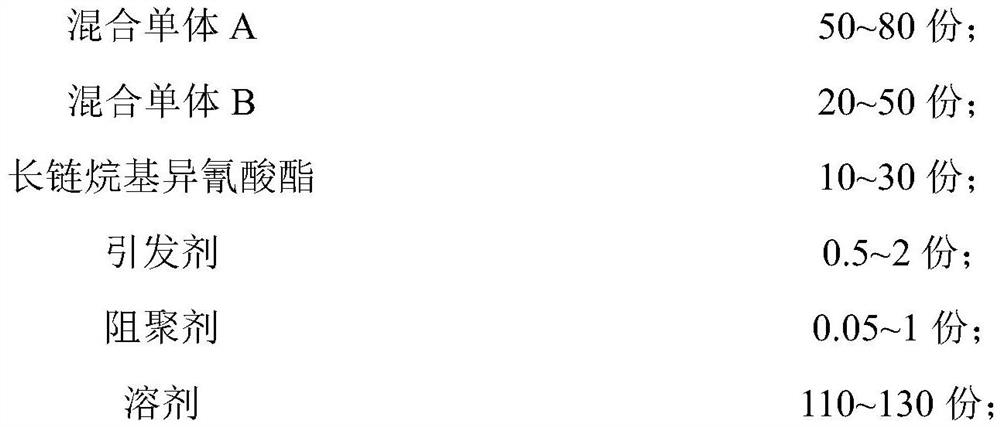

Method used

Image

Examples

Embodiment 1

[0026] Divide the solvent into three parts, and add the first part of the solvent into the reaction kettle according to the components specified in Table 1, stir and mix evenly, heat up to 55°C for heat preservation; then take the mixed monomer A and the initiator for mixing, Make component 1, then take mixed monomer B and mix to make component 2; then add component 1 and component 2 dropwise in the reaction kettle at the same time, the dropping time is 1 hour, keep warm for 2 hours after dropping, The temperature is controlled at 70°C; after the heat preservation is over, first add the polymerization inhibitor and the second part of the solvent into the reactor and mix well, then add the long-chain alkyl isocyanate to react, the reaction temperature is 60°C, and the reaction time is 2 hours; Finally, the third part of solvent was added for dilution to prepare an acrylate resin for long-chain alkyl isocyanate modified ink with a solid content of 50%.

[0027] Among them, the s...

Embodiment 2

[0029] Divide the solvent into three parts, and add the first part of the solvent into the reaction kettle according to the components specified in Table 1, stir and mix evenly, heat up to 75°C and keep it warm; then take the mixed monomer A and the initiator for mixing, Make component 1, then take mixed monomer B and mix to make component 2; then add component 1 and component 2 dropwise in the reaction kettle at the same time, the dropping time is 2 hours, keep warm for 3 hours after dropping, The temperature is controlled at 80°C; after the heat preservation is over, first add the polymerization inhibitor and the second part of the solvent into the reactor and mix them evenly, then add the long-chain alkyl isocyanate to react, the reaction temperature is 65°C, and the reaction time is 1 hour; Finally, the third part of solvent was added for dilution to prepare an acrylate resin for long-chain alkyl isocyanate modified ink with a solid content of 50%.

[0030] Among them, the...

Embodiment 3

[0032] Divide the solvent into three parts, and add the first part of the solvent into the reaction kettle according to the components specified in Table 1, stir and mix evenly, heat up to 90°C for heat preservation; then take the mixed monomer A and the initiator for mixing, Make component 1, then take mixed monomer B and mix to make component 2; then add component 1 and component 2 dropwise in the reaction kettle at the same time, the dropping time is 3 hours, keep warm for 5 hours after dropping, The temperature is controlled at 90°C; after the heat preservation is over, first add the polymerization inhibitor and the second part of the solvent into the reactor and mix them evenly, then add the long-chain alkyl isocyanate to react, the reaction temperature is 70°C, and the reaction time is 3 hours; Finally, the third part of solvent was added for dilution to prepare an acrylate resin for long-chain alkyl isocyanate modified ink with a solid content of 50%.

[0033] Among the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com