High-Fe content Cu-Fe series alloy material and preparation method thereof

An alloy material, cu-fe technology, applied in the field of metal composite materials, can solve the problems of difficult alloy processing, high equipment requirements, and singleness, and achieve the effect of high strength and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

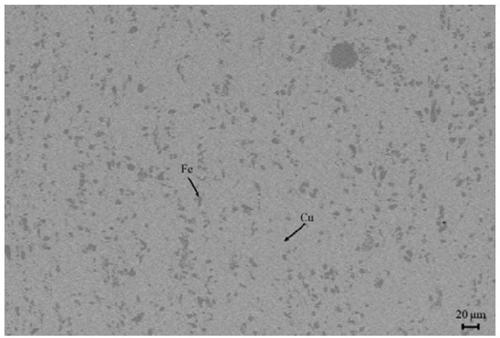

Image

Examples

Embodiment 1

[0048] This example provides a Cu-Fe alloy material with high iron content, which includes the following components in mass percentage:

[0049] Fe 5.0%, FeS 0.02%, Mn 0.05%, Sr 0.03%, Cu 94.9%.

Embodiment 2

[0051] This example provides a Cu-Fe alloy material with high iron content, which includes the following components in mass percentage:

[0052] Fe 20.0%, FeS 0.1%, Mn 0.1%, Sr 0.1%, Cu 79.7%.

Embodiment 3

[0054] This example provides a Cu-Fe alloy material with high iron content, which includes the following components in mass percentage:

[0055] Fe 12%, FeS 0.05%, Mn 0.07%, Sr 0.06%, Cu 87.82%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com