Water-based environment-friendly flame-retardant adhesive and preparation method thereof

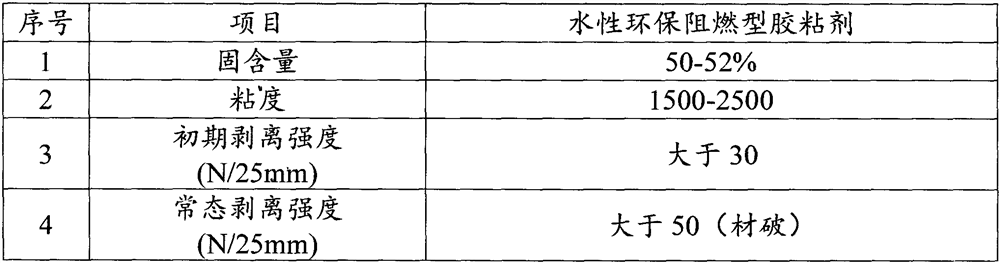

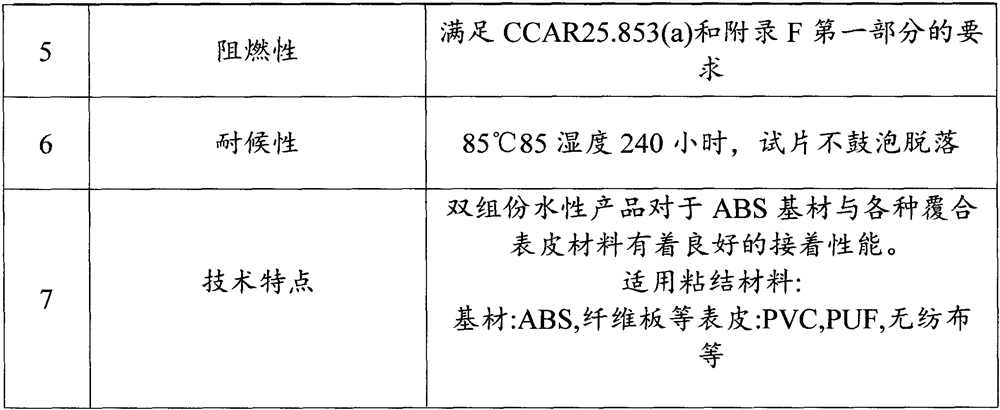

A flame-retardant, adhesive technology, used in adhesives, polyurea/polyurethane adhesives, polymer adhesive additives, etc., can solve the problems of easy hydrolysis, poor weather resistance, short interior use time, and poor fire resistance and fire resistance. , to achieve the effect of long open time, fast drying and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a preparation method of a water-based environmentally friendly flame-retardant adhesive, which comprises the following steps:

[0046] Add water-based polyurethane emulsion and pH stabilizer to the reaction kettle according to the above mass parts, and stir for 10-20 minutes;

[0047] Add flame retardant and stir for 10-20 minutes;

[0048] Add anti-hydrolysis agent and stir for 10-20 minutes;

[0049] Add hydrophilic fumed silica and stir for 30-60 minutes;

[0050] Add VAE emulsion and stir for 15-20 minutes;

[0051] Add water-based tackifying resin and stir for 15-20 minutes;

[0052] Add defoamer and stir for 10-20 minutes;

[0053] Then add 0.2-0.5 parts of rheology modifier, stir evenly, and filter out the material.

[0054] In order to ensure that the aqueous fumed silica is fully and uniformly wetted and dispersed, for example, after adding the aqueous fumed silica, the silica is dispersed by shaking, mechanical stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com