Large-buried-depth tunnel top vertical shaft backfilling load-reducing structure and construction method thereof

A construction method and technology for shafts, which are applied to shaft equipment, tunnels, fillings, etc., can solve the problems of difficult reinforcement of underlying tunnels, heavy backfilling structure, and easy collapse of wellbore holes, etc. Good performance, significant effect of preventing water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

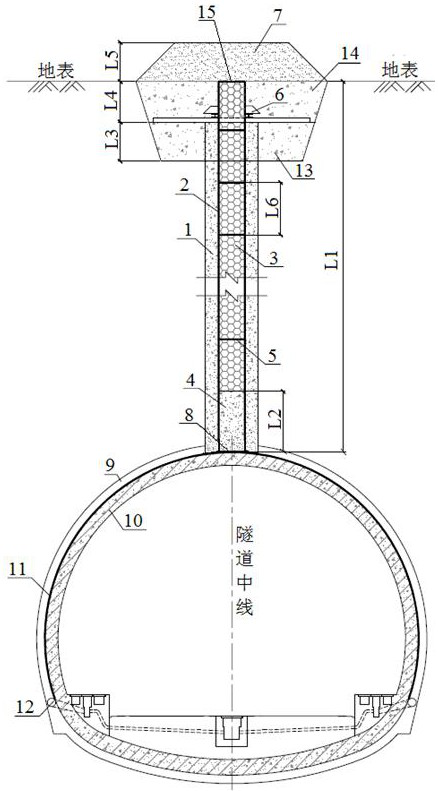

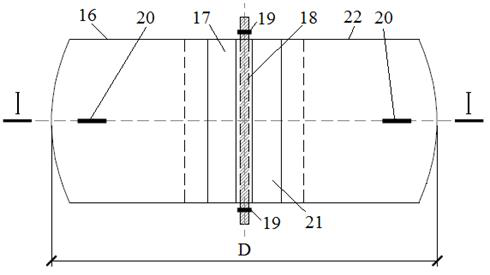

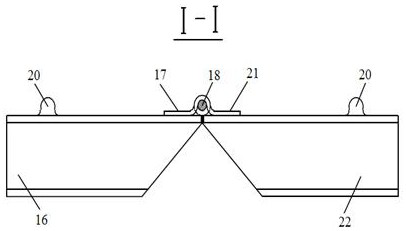

[0035] Such as figure 1 As shown, the top shaft backfill load reduction structure of the present invention includes the existing shaft 1, the bottom of the shaft 1 is provided with a bottom sealing plate 8, and the bottom sealing plate 8 is an arc-shaped plate, and its concave surface is in line with the initial support 9 of the tunnel. The outer edges match; the shaft 1 is provided with a protective tube 2 of height L1 that closely fits the inner wall of the shaft 1; the top of the protective tube 2 extends out of the shaft 1, and the top surface of the protective tube 2 is flush with the ground surface; The protective tube 2 is formed by successively connecting a plurality of cylindrical steel casings with an inner diameter of D, and two adjacent steel casings are threaded or welded; the bottom end of the protective tube 2 is in con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com