Steam turbine rotating speed control method based on valve characteristic curves under extreme working condition

A technology with characteristic curves and extreme working conditions, applied in steam engine installations, mechanical equipment, engine components, etc., it can solve problems such as poor linearization, steam turbine damage, and extremely high requirements for operators, so as to reduce monitoring and operation workload, and reduce safety. The effect of improving the performance and economy, and shortening the grid connection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with embodiment.

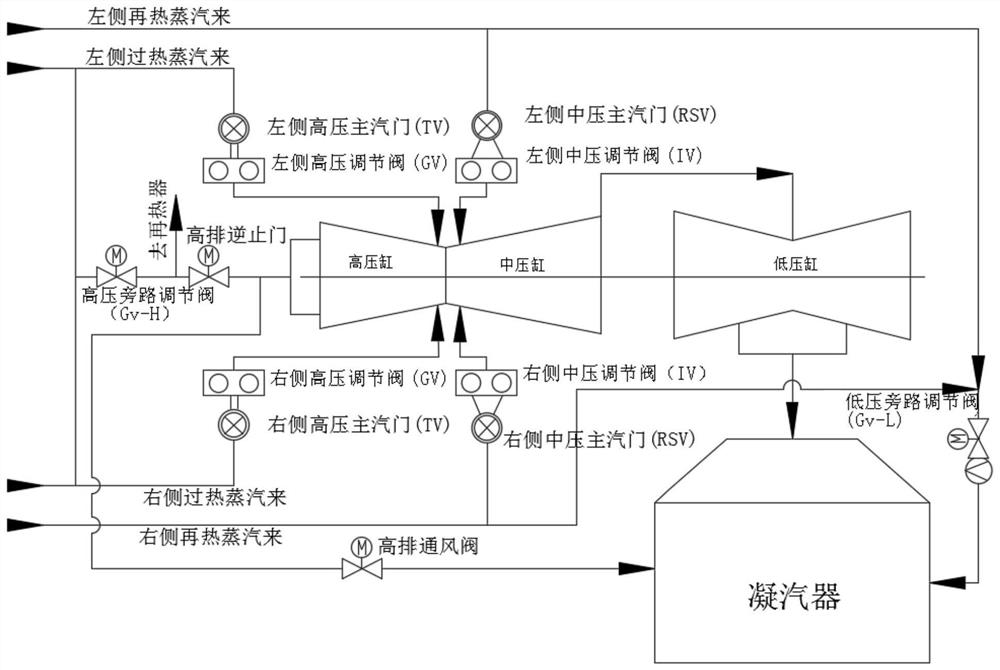

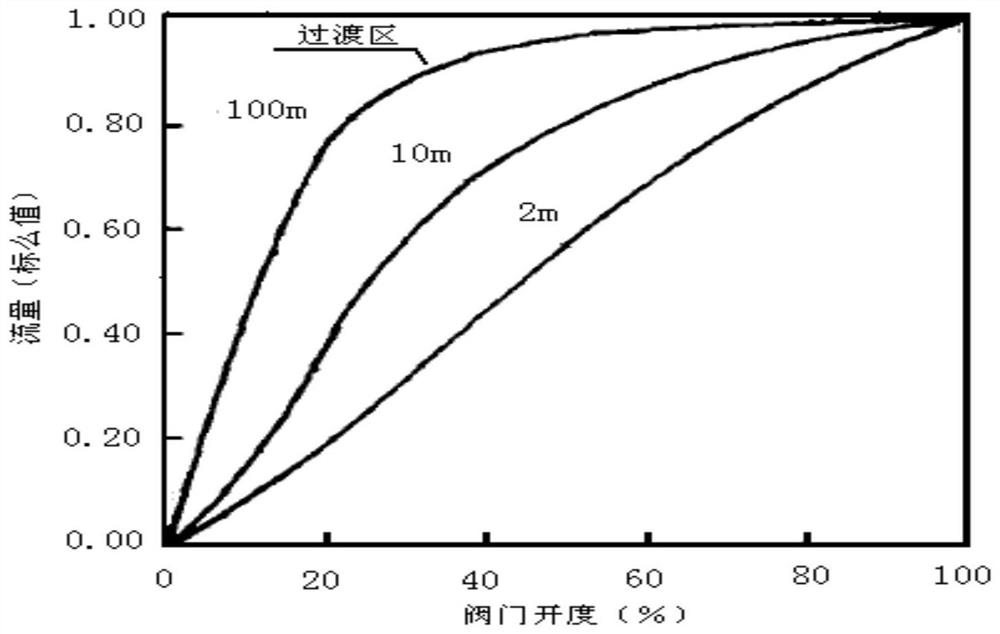

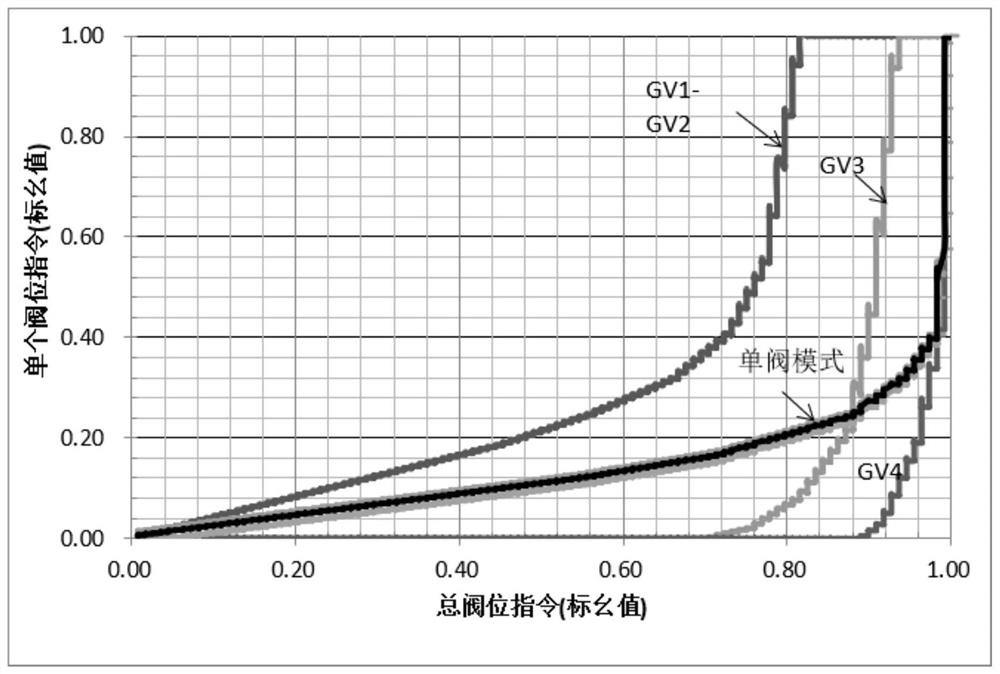

[0033] During specific implementation: if Figure 4 ~ Figure 9 As shown, a steam turbine speed control method based on the valve characteristic curve under extreme working conditions mainly adopts the following steps:

[0034]Step 1: The control module is triggered by an externally connected extreme signal. When the system experiences steam turbine unit load shedding, or the boiler is turned off, and the steam turbine unit needs to maintain 3000r / min operation under the condition of high-quality steam parameters, it will be put into operation immediately. The control logic implements self-judgment to set corresponding main reheat steam parameter (pressure and temperature) setting values.

[0035] Among them, the set pressure of reheat steam is obtained by the following steps:

[0036] Obtain the minimum steam flow required when the rotor is at a constant speed of 3000r / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com