Space laser structure

A laser and space technology, applied in the field of lasers, can solve problems affecting laser life and reliability, optical path changes, and reduce the life of optical devices, etc., to solve the impact of structural deformation, reduce the impact of structural deformation, and improve the effect of on-orbit life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

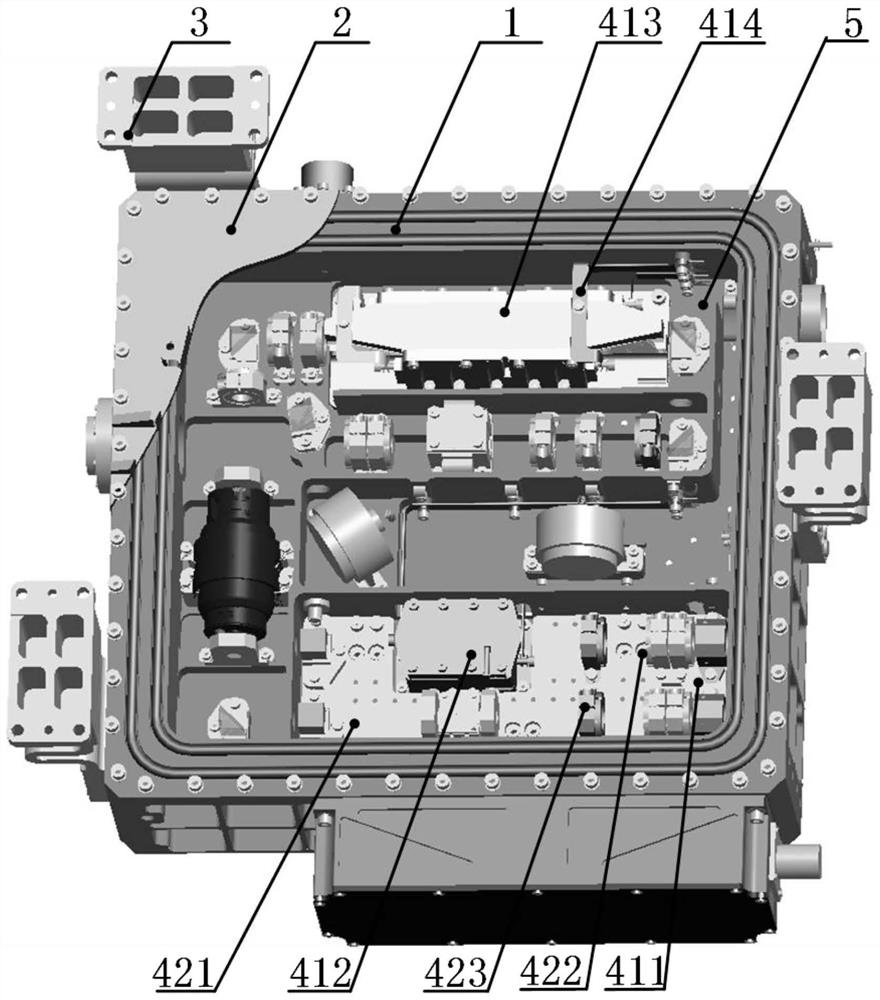

[0041] Such as figure 1 As shown, a space laser structure includes a laser housing 1, a cover plate 2 forming a sealing structure with the laser housing 1, and legs 3 arranged around the laser housing 1 for fixing the laser housing 1 and the satellite body and a laser assembly 4 disposed inside the laser housing 1;

[0042] The laser housing 1 and the cover plate 2 are sealed by an O-ring;

[0043] The laser housing 1 and the laser assembly 4 are provided with a protective layer 5, the protective layer 5 is clean air used to prolong the life of the laser assembly 4, and the pressure of the protective layer 5 is greater than 1 atmosphere;

[0044] The laser assembly 4 includes components 41 and an isolation assembly 42 for increasing mechanical stability. Some components 41 are directly fixed on the inner wall of the laser housing 1, and other components 41 are fixed to the laser housing 1 through the isolation assembly 42. .

Embodiment 2

[0046] Such as figure 1 As shown, a space laser structure includes a laser housing 1, a cover plate 2 forming a sealing structure with the laser housing 1, and legs 3 arranged around the laser housing 1 for fixing the laser housing 1 and the satellite body and a laser assembly 4 disposed inside the laser housing 1;

[0047] The laser housing 1 and the cover plate 2 are sealed by an O-ring, and the O-ring is a double O-ring;

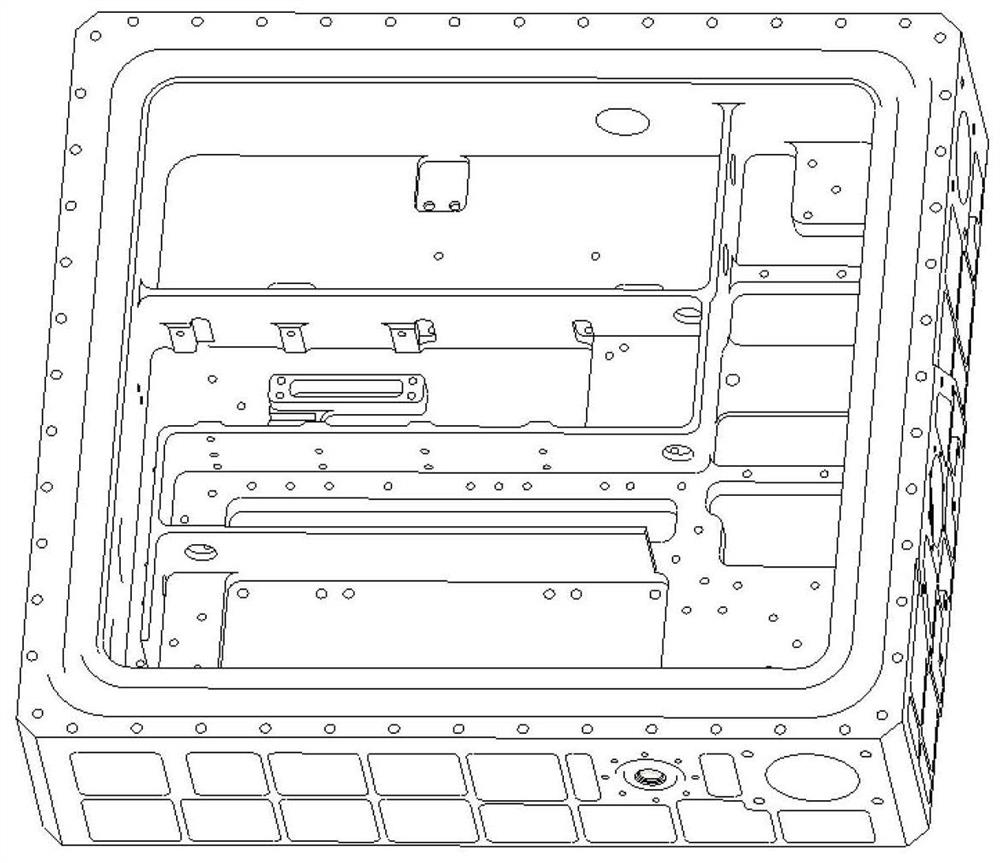

[0048] The laser housing 1 and cover plate 2 are made of aluminum 6061, such as figure 2 As shown, the side wall of the laser housing 1 is provided with lightening grooves;

[0049] The laser housing 1 and the laser assembly 4 are provided with a protective layer 5, the protective layer 5 is clean air used to prolong the life of the laser assembly 4, and the pressure of the protective layer 5 is greater than 1 atmosphere;

[0050] The material of leg 3 is TC17;

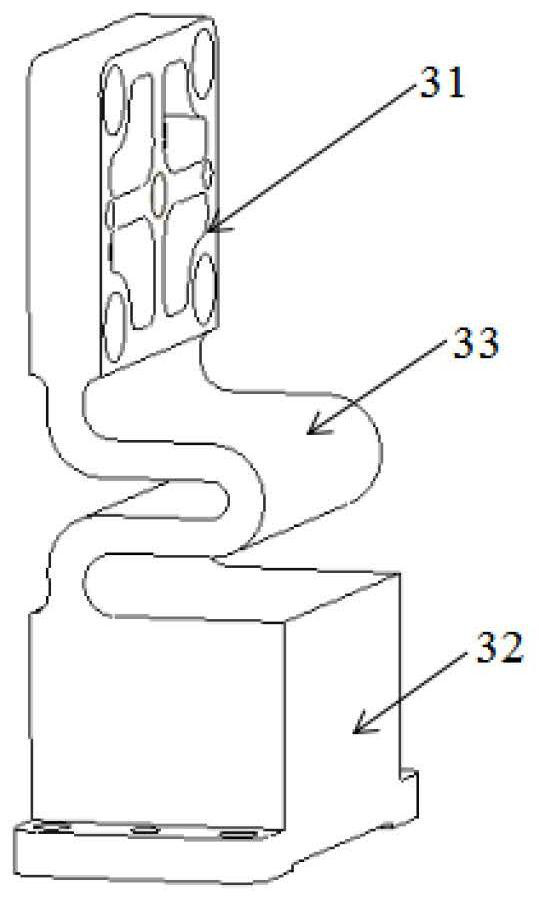

[0051] Such as image 3As shown, the leg 3 includes a first fixing seat 31 for fixing w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com