Central hygiene system

A hygienic and central technology, applied in the field of the central sanitation system, can solve the problems of large floor space and low work efficiency, and achieve the effect of reducing floor space, saving time, and reducing waste of manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

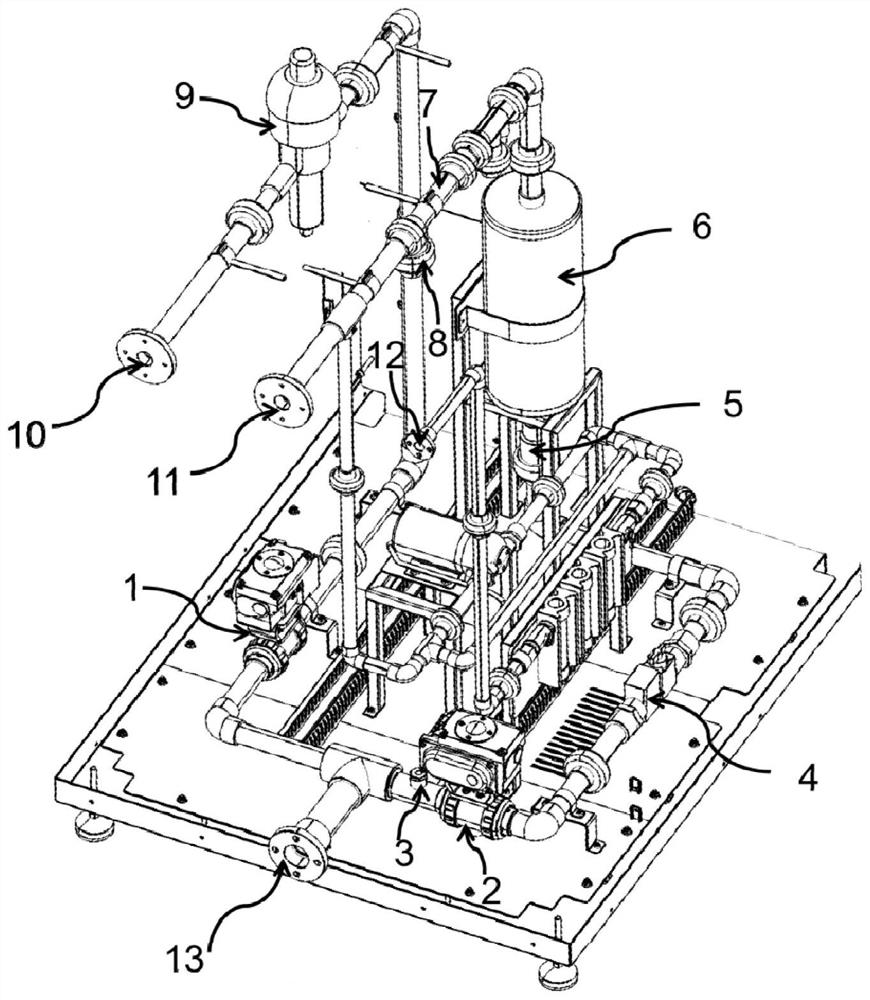

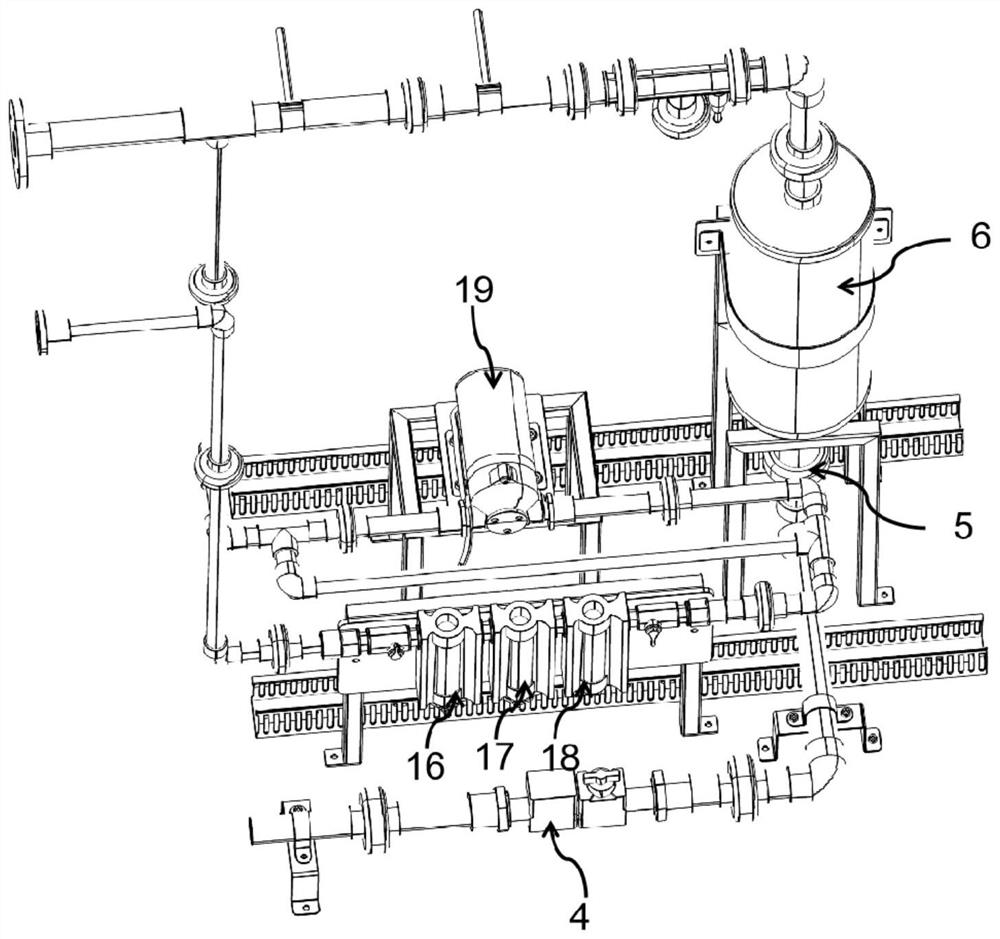

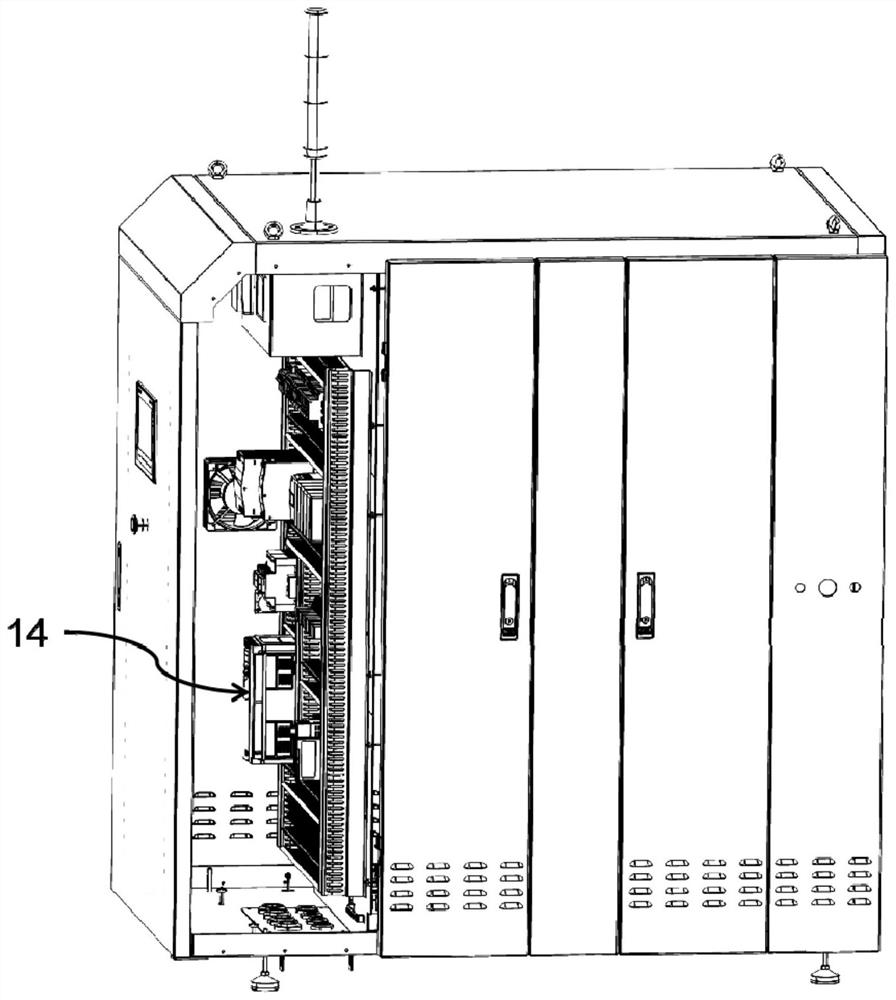

[0019] see Figure 1 to Figure 5 , the central sanitation system includes a box body 15, which is provided with a foam cleaning module, an electrolyzed water module and an electrical module 14, and the box body covers an area of 1 to 2 m 2 .

[0020] The foam cleaning module includes a first electric ball valve 1 , a proportional pump 9 , a first check valve 5 and a foam water outlet 10 . The first electric ball valve 1 and the water inlet 13, the first electric ball valve 1 and the proportional pump 9, the proportional pump 9 and the first check valve 5, and the first check valve 5 and the foam water outlet 10 are all connected by pipelines.

[0021] The electrolyzed water module includes a control device, an electrolyzed water generating device, and a detecting device. The control device, the electrolyzed water generating device and the detection device are sequentially connected through pipelines. The control device includes a pressure transmitter 3 , a second electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com