Method for preparing artificial graphite negative electrode material from resistance material

A technology of artificial graphite negative electrode and resistance material, which is applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve the problems of producing artificial graphite negative electrode material, backward treatment method of resistance material, high cost of artificial graphite, etc., and achieve improved kinetic performance , low cost, easy to process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment is a method for preparing a low-cost lithium-ion battery negative electrode material. Specific steps are as follows:

[0036] (1) The resistance material (2-10 cm in diameter) produced by the graphitization crucible furnace is coarsely crushed by a coarse crusher (roller-jaw-crusher integrated machine), and the average particle size D50 is 100.0-200.0 μm.

[0037] (2) The coarsely crushed graphitized resistor material obtained in step (1) is crushed through a pulverizer (mechanical mill 500), and the average particle diameter D50 is 14.0-19.0 μm.

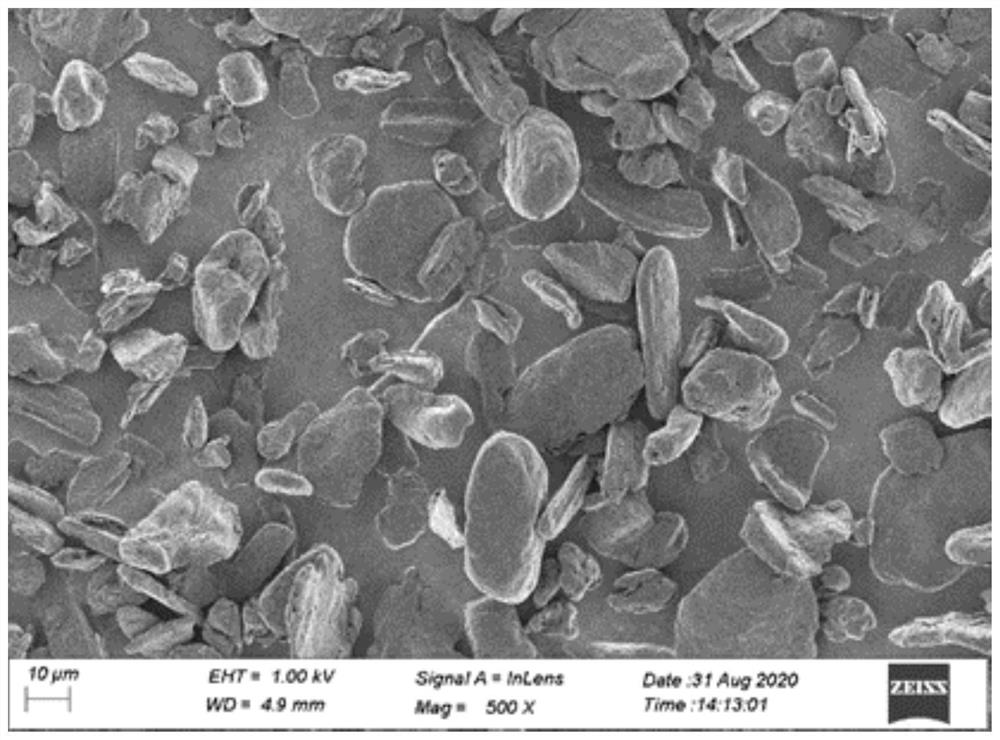

[0038] (3) Pass the pulverized resistance material obtained in step (2) through a shaping machine (intermittent shaping machine 800) to remove fine powder, improve the degree of sphericity to improve vibration, Dmin≥2.0μm, and the average particle size D50 is 16.0~ 19.0μm, the vibration is 0.85~1.0g / cm 3 .

[0039] (4) The reshaped resistance material obtained in step (3) is passed through an electromagneti...

Embodiment 2

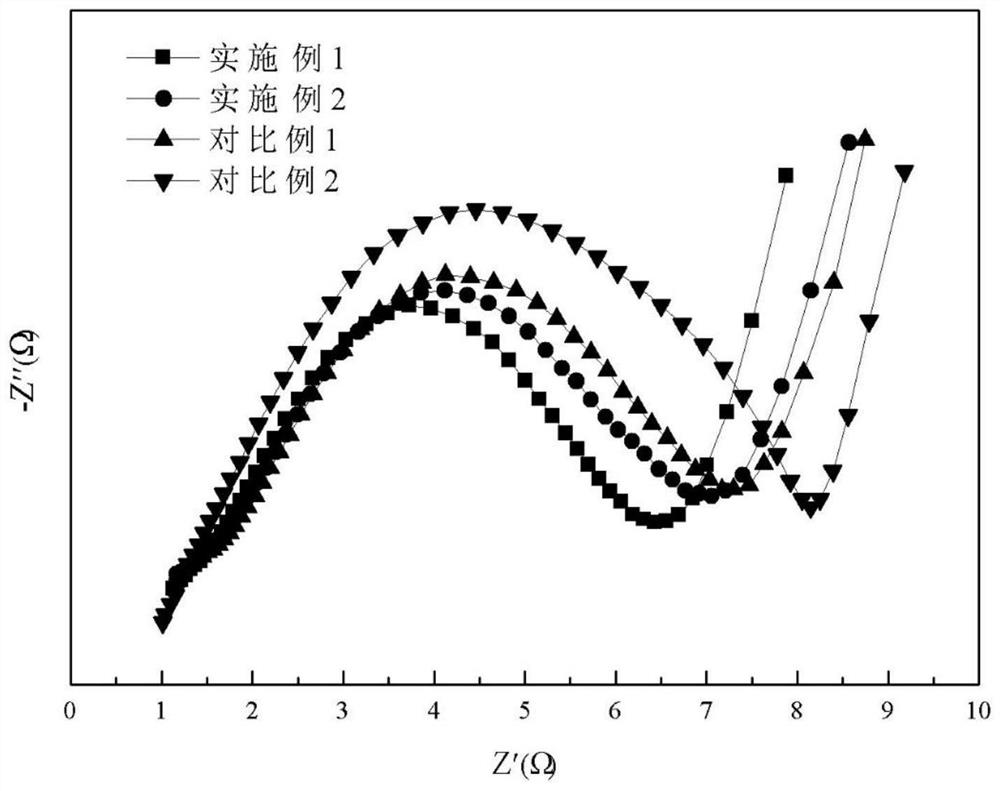

[0045] The difference between this embodiment and Example 1 is that the crushing equipment used in step (2): mechanical mill 500 and the 800 shaping machine used in step (3) are generally replaced with 60 spherical shaping equipment, and the resistance material Dmin ≥2.0μm, the ratio of resistance material to asphalt is 100:3, other things remain unchanged. The average particle size D50 of graphite coated with resistance material is 16.0-19.0 μm, and the tap density is 0.87 g / cm 3 , the specific surface area is 4.0m 2 / g, magnetic substance content ~ 1.5ppm, discharge capacity 353.1mAh / g, initial efficiency 90.5%, 1C / 1C 500 cycle capacity retention rate 92.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com