Device and method for rapid cooling of high temperature gas

A high-temperature gas, rapid cooling technology, applied in the field of rapid cooling devices and processes, to overcome the problem of limited application, safe and reliable cooling, and reduce the risk of cooling blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

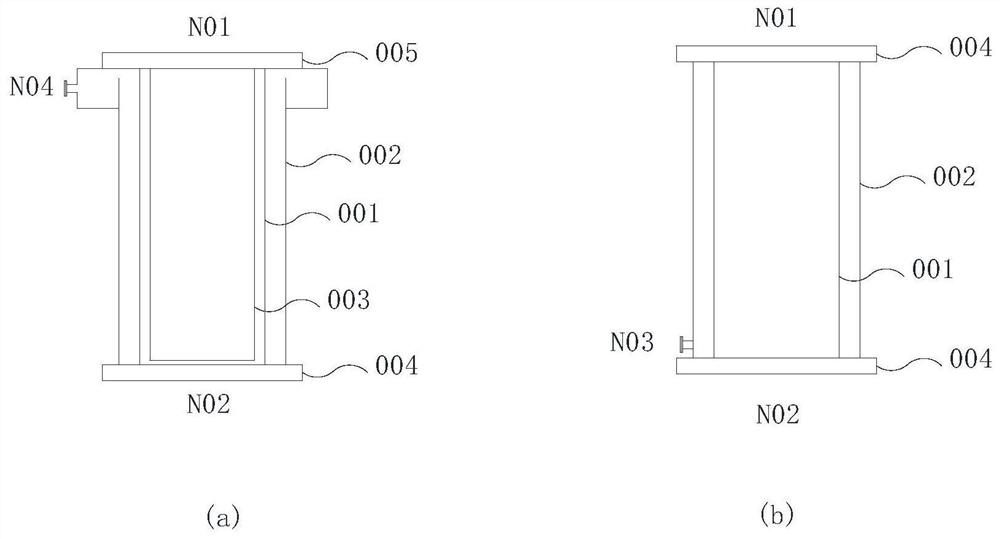

Embodiment 1

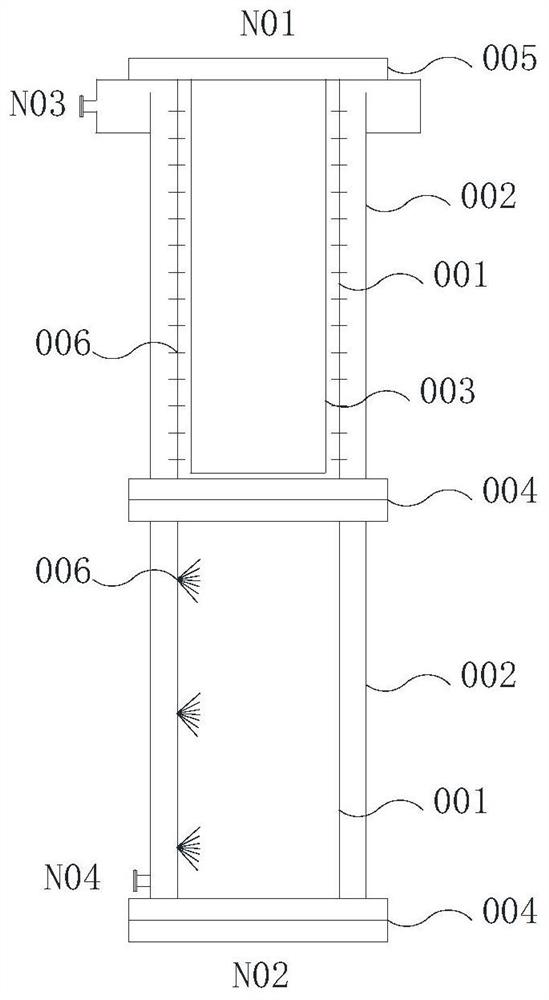

[0036] use as figure 2 The quenching device shown is composed of two sections a+b. The cylindrical casing of the quenching device has a diameter of 400 mm and is divided into two sections, the first section is 1.0 m in height, and the second section is 1.0 m in height. The distance between the cylindrical shell and the jacket of each section is 30mm, the first section has an inner cylinder, the second section has no inner cylinder, and the distance between the first cylindrical shell and the inner cylinder is 5mm , the cylindrical shell of the quenching device is made of tantalum material, the inner side of the jacket outside the shell is CS lined with tantalum, the inner cylinder is made of tantalum material, the nozzle material is made of tantalum material, the thickness of the cylindrical shell is 4mm, and the jacket outside the shell The thickness is 20mm, the thickness of the inner cylinder is 3mm, and the thickness of the lining material inside the jacket is 1.2mm.

...

Embodiment 2

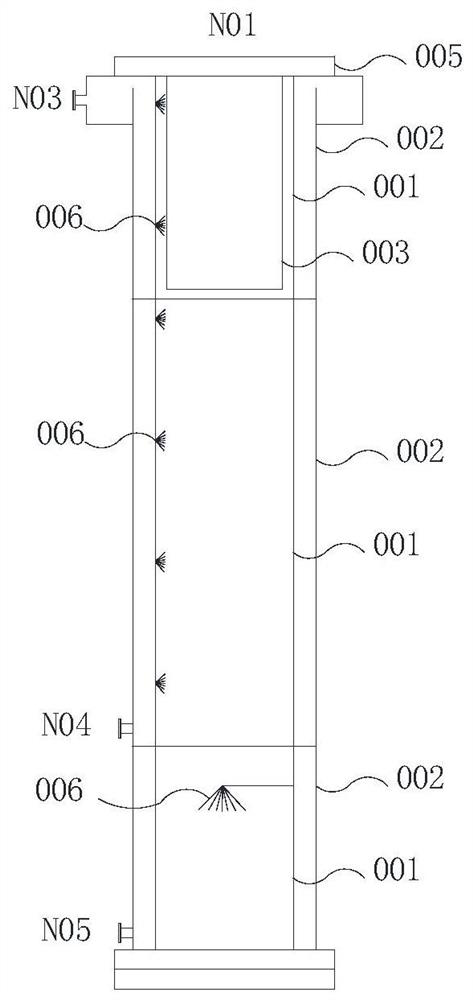

[0041] use as image 3 The quenching device shown is composed of sections a+b+b. The cylindrical shell of the quenching device has a diameter of 2000mm and is divided into three sections. The height of the first section is 0.5m, the height of the second section is 1m, and the height of the third section is 0.5m. The connection method of each section is welding. The distance between each cylindrical shell and the jacket is 50mm, the first section has an inner cylinder, the second and third sections have no inner cylinder, the distance between the cylindrical shell and the inner cylinder is 5mm, and the quenching device The cylindrical shell is 304, the inner side of the jacket outside the shell is 304, the material of the nozzle is 304, the material of the inner cylinder is 304, the thickness of the cylindrical shell is 5mm, the thickness of the jacket outside the shell is 15mm, and the inner cylinder The thickness is 1.5mm.

[0042]The inner member of the cylindrical shell o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com