Trough type solar energy and high-voltage electric field drying pipe

A high-voltage electric field drying, trough solar technology, applied in the direction of solar thermal power generation, solar thermal energy, solar thermal collectors, etc., can solve the problems of loss of large thermal energy and electric energy, sustainable utilization of unfavorable energy, consumption of large labor force, etc., to save energy The effect of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

[0020] The invention provides a trough solar high voltage electric field drying pipe.

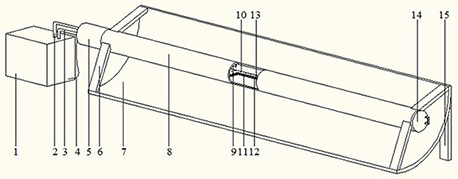

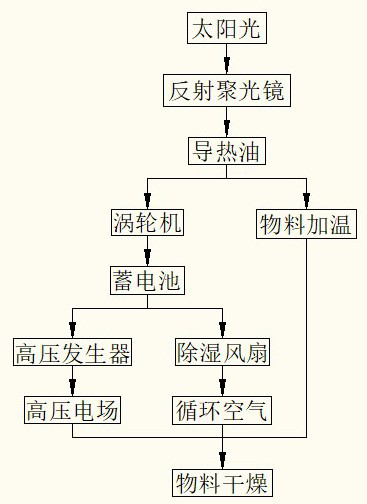

[0021] Specifically, the material is placed in the storage board 10, the heat collecting pipe door 14 is closed, the trough solar high-voltage electric field drying is started, the reflective concentrator 7 reflects the solar energy to the heat collecting material pipe 8, and the heat conducting oil 46 in the lower part continues to heat up, so that the heat collecting The material pipe 8 is heated as a whole, and at the same time, the heat transfer oil 13 passes through the end of the left heat collecting pipe 5 and then passes through the heat exchange pipe 2 to the central cabinet 1, and uses the temperature difference to drive the turbine to generate electricity, and then circulates through the oil pump; the electric energy is stored in the battery of the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com