Method for detecting acetonitrile content in composite solid propellant by using gas chromatography

A technology of solid propellant and gas chromatography, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of storage aging performance hazards, combustion performance, energy performance and mechanical performance adverse effects, etc., to achieve accurate measurement and good measurement effect , good peak effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

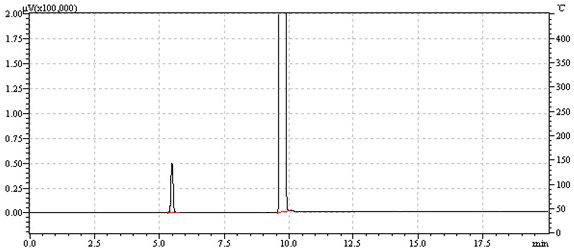

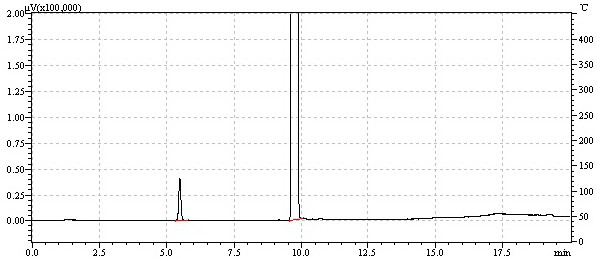

Image

Examples

Embodiment 1

[0021] A method utilizing gas chromatography to detect acetonitrile content in composite solid propellant, comprising the steps:

[0022] S1: Preparation of internal standard solution

[0023] Weigh analytically pure grade acetonitrile into 100mL volumetric flasks, add tetrahydrofuran to dilute to constant volume, shake well, and prepare mass concentrations of 0.8mg / mL, 1.6mg / mL, 2.4mg / mL, 4.0mg / mL, 8.0 mg / mL acetonitrile solution in tetrahydrofuran, as the internal standard sample solution;

[0024] S2: Preparation of sample solution to be tested

[0025] Weigh about 2g of propellant slurry sample, put it into a 6mL reagent bottle, add 2.0mL of analytically pure tetrahydrofuran with a pipette, stir quickly, cover the bottle tightly, dissolve for about 12h, and take the supernatant as The sample solution to be tested;

[0026] S3: Selection of gas chromatography detection conditions

[0027] Chromatograph: SHIMADZU GC-2010-Pro gas chromatograph;

[0028] Chromatographic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com