Xanthogen compound dispersion, conjugated-diene-based polymer latex composition, and film molded body

A technology of conjugated diene and xanthogen, which is applied in the fields of xanthogen compound dispersion, conjugated diene polymer latex composition and film forming body, can solve problems such as delayed-type allergy and the like, and achieves inhibition of delayed-type allergy. Allergy, immediate allergy suppression, pinhole suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

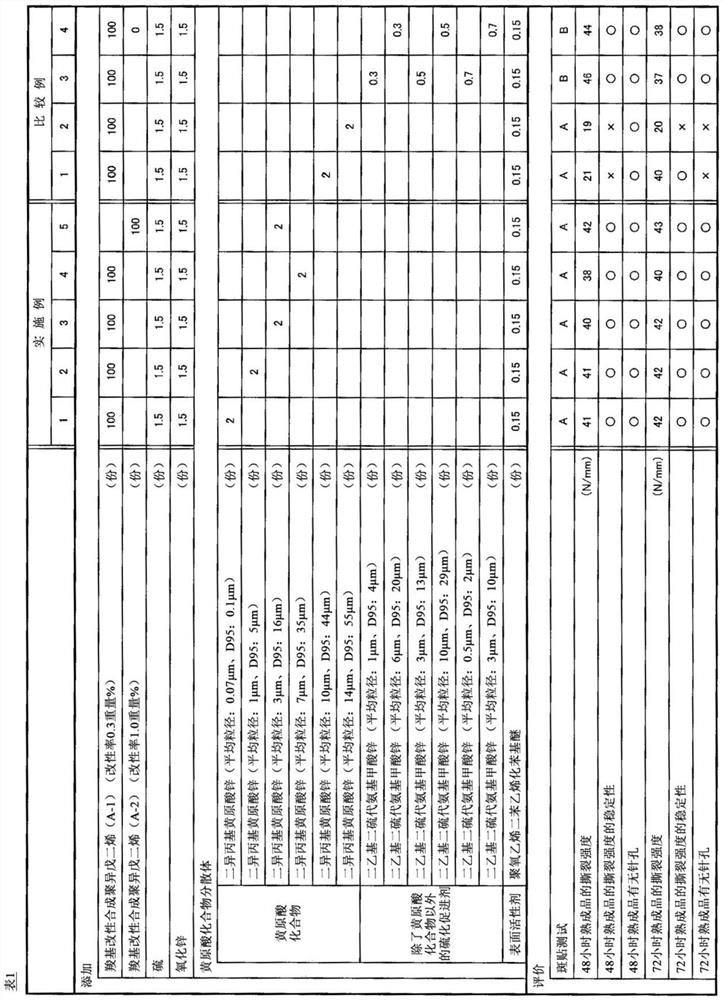

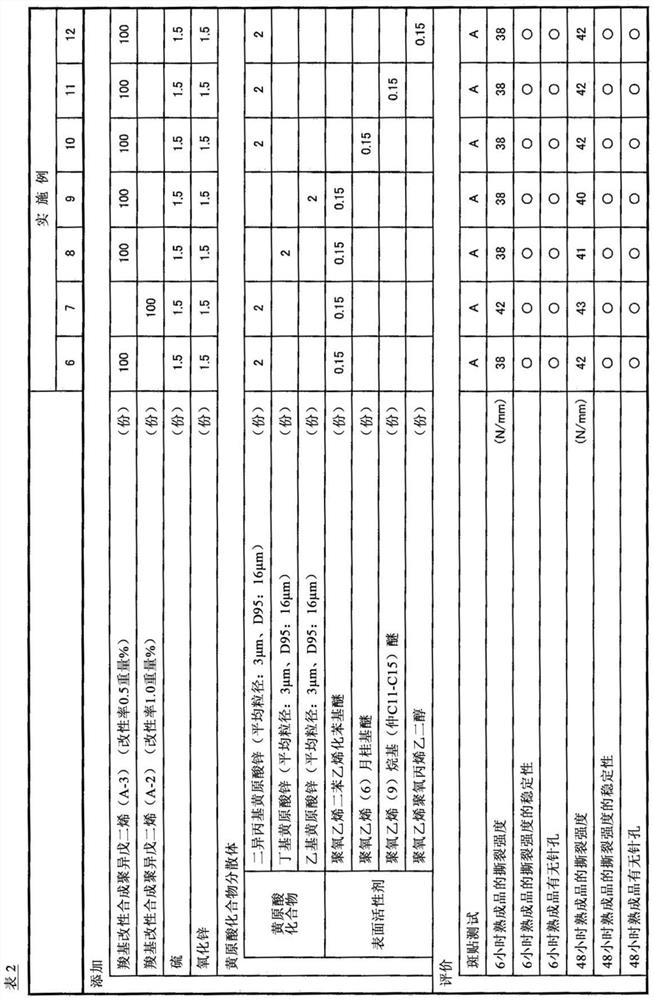

[0172] Hereafter, although an Example demonstrates this invention in detail, this invention is not limited to these Examples. In addition, unless otherwise indicated, the following "parts" are based on weight. In addition, various physical properties were measured as follows.

[0173]

[0174] A 2-g sample (weight: X2) was accurately weighed in an aluminum pan (weight: X1), and dried in a hot air dryer at 105° C. for 2 hours. Next, after cooling in a desiccator, the weight (weight: X3) of the whole aluminum pan was measured, and the solid content concentration was calculated from the following formula.

[0175] Solid content concentration (weight %)=(X3-X1)×100 / X2

[0176]

[0177] Carboxyl-modified synthetic polyisoprene constituting the latex of carboxyl-modified synthetic polyisoprene is neutralized and titrated using an aqueous sodium hydroxide solution to determine the number of carboxyl groups in carboxyl-modified synthetic polyisoprene . Next, based on the obtai...

manufacture example 1

[0196] (Manufacture of latex of carboxy-modified synthetic polyisoprene (A-1))

[0197] Synthetic polyisoprene with a weight average molecular weight of 1,300,000 (trade name "NIPOL IR2200L", manufactured by Nippon Zeon Co., Ltd., homopolymer of isoprene, cis bond unit content: 98%) was mixed with cyclohexane, The temperature was raised to 60°C while stirring to dissolve, and a synthetic polyisoprene cyclohexane solution (a) (solid content concentration: 8% by weight) having a viscosity of 12,000 mPa·s measured with a B-type viscometer was prepared.

[0198] On the other hand, water was added to 20 parts of sodium rosinate, and the temperature was raised to 60° C. for dissolution to prepare an anionic surfactant (b) having a concentration of 1.5% by weight.

[0199] Next, the above-mentioned cyclohexane solution (a) and the above-mentioned anionic surfactant aqueous solution (b) were mixed in a weight ratio of 1:1.5 using a mixer (trade name "Multiline mixer MS26-MMR-5.5L" , ...

manufacture example 2

[0205] (Manufacture of latex of carboxy-modified synthetic polyisoprene (A-2))

[0206] Except having changed the usage-amount of methacrylic acid into 5 parts, it carried out similarly to manufacture example 1, and obtained the latex of the carboxyl-modified synthetic polyisoprene (A-2) whose solid content concentration was 55%. The obtained latex of the carboxy group-modified synthetic polyisoprene (A-2) was measured for the modification rate of the monomer having a carboxyl group according to the method described above, and the modification rate was 1.0% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com