Method for improving foamability or emulsibility of sodium caseinate

A sodium caseinate, foaming technology, applied in animal protein processing, food science and other directions, can solve the problems of easy depolymerization and pH instability of protein-polysaccharide complexes, and achieve simple and effective destabilizing aggregation and low price. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

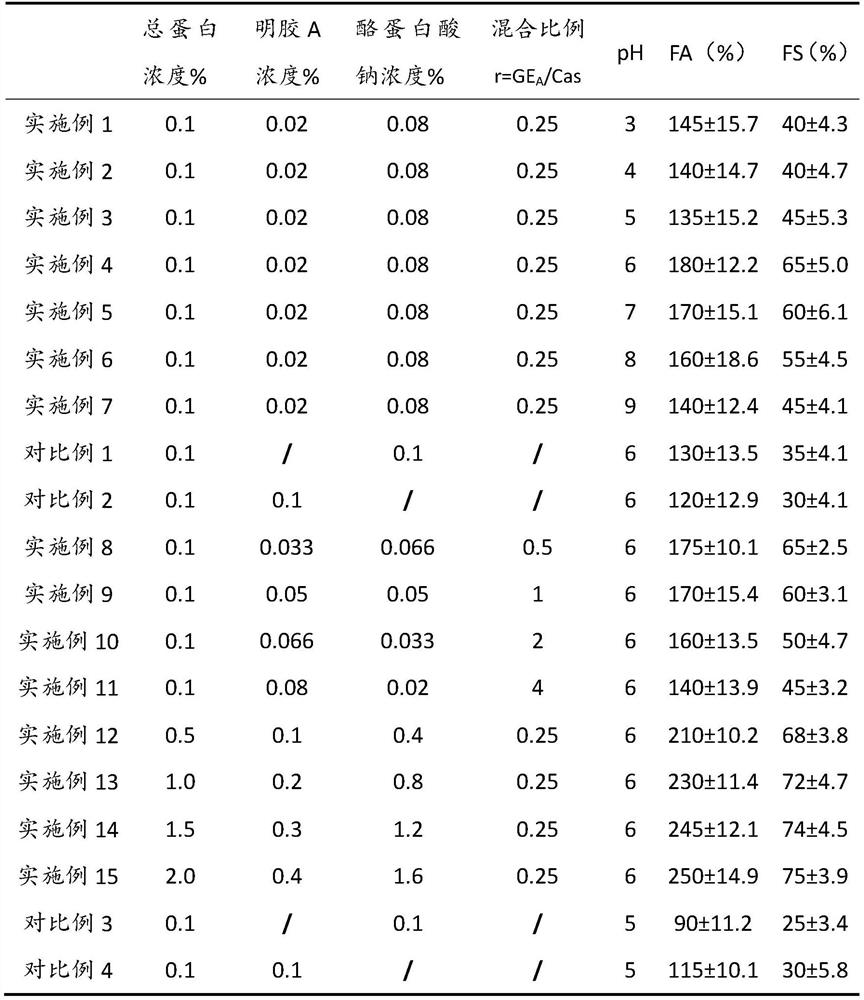

Examples

Embodiment 16-30

[0031] Embodiment 16-30 provides a kind of method utilizing gelatin A to improve the emulsification of sodium caseinate, comprising the steps:

[0032] Step 1: Weigh a certain mass of sodium caseinate powder and dissolve it in deionized water, heat and dissolve in a water bath at 45°C, and prepare a sodium caseinate solution with the concentration shown in Table 2;

[0033] Step 2: Weigh a certain amount of gelatin A powder and dissolve it in deionized water, heat and dissolve in a water bath at 45°C, and prepare a gelatin A solution with the concentration shown in Table 2;

[0034] Step 3: Mix the gelatin A and sodium caseinate solution in step 1 and step 2 to prepare the gelatin A / sodium caseinate mixed system in the ratio shown in Table 2. Hydrochloric acid and sodium hydroxide were used to adjust the pH, and stirring was continued at 45°C and 300 rpm for 30 minutes to obtain a gelatin A / sodium caseinate mixture.

[0035] Step 4: Mix the gelatin A / sodium caseinate mixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com