Automatic liquid transfer device

A pipetting and automatic technology, applied in the direction of measuring tube/pipette, etc., to achieve the effect of multi-depth liquid transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

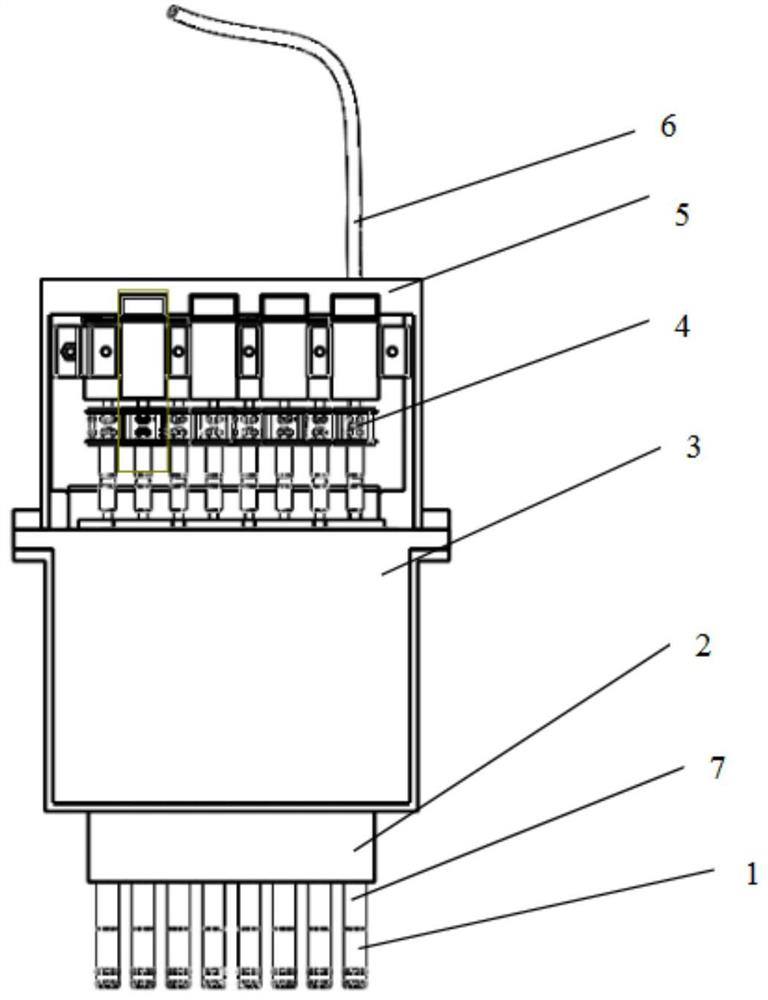

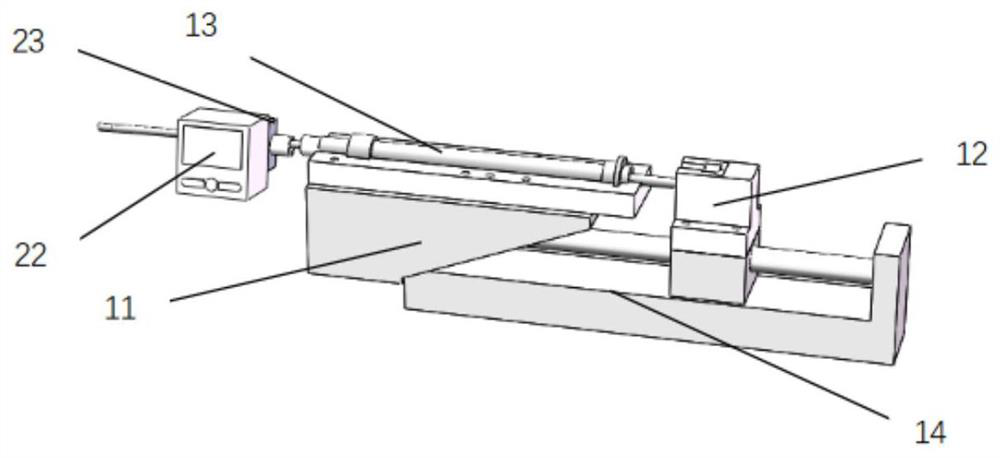

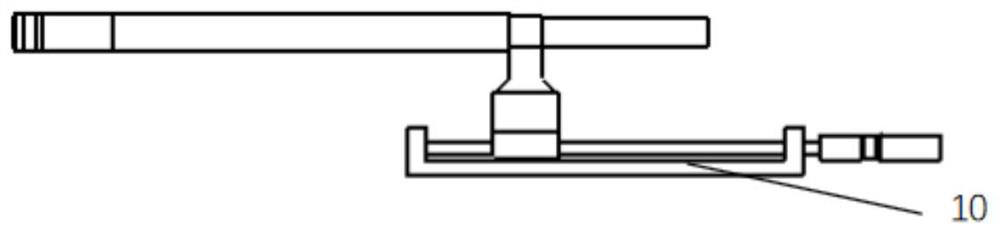

[0033] An automatic liquid pipetting device, such as figure 1 As shown, it includes the following parts: pipette gun shell, pipette gun top cover, pipette gun inner tube, first sliding table guide rail, second sliding table guide rail, motor, thin tube, syringe, tip loading and unloading shell.

[0034] Among them, the number of inner tubes of the pipette is increased or decreased according to actual needs, figure 1 Taking 8 pipettes as an example, any number of 1-8 channels can be pipetted at multiple depths according to the needs. The inner sleeve covered by the inner tube of the pipette gun and the outer sleeve installed on the tip loading and unloading shell form a parallel slide for the inner tube to move up and down. The inner tube of the pipette can move in the channel with low friction and no deviation, which is used for the removal of disposable pipette tips.

[0035] Among them, the relative position of the inner tube of the pipette is determined by the internal s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com