Online coating rolling device and control method thereof

A rolling device and coating technology, which is applied to the device for coating liquid on the surface, coating, spraying device, etc., can solve the problem of reduced fluidity, low production efficiency of secondary clamping of parts, and reduced rolling effect. and other problems, to achieve the effect of high rolling quality, uniform force and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

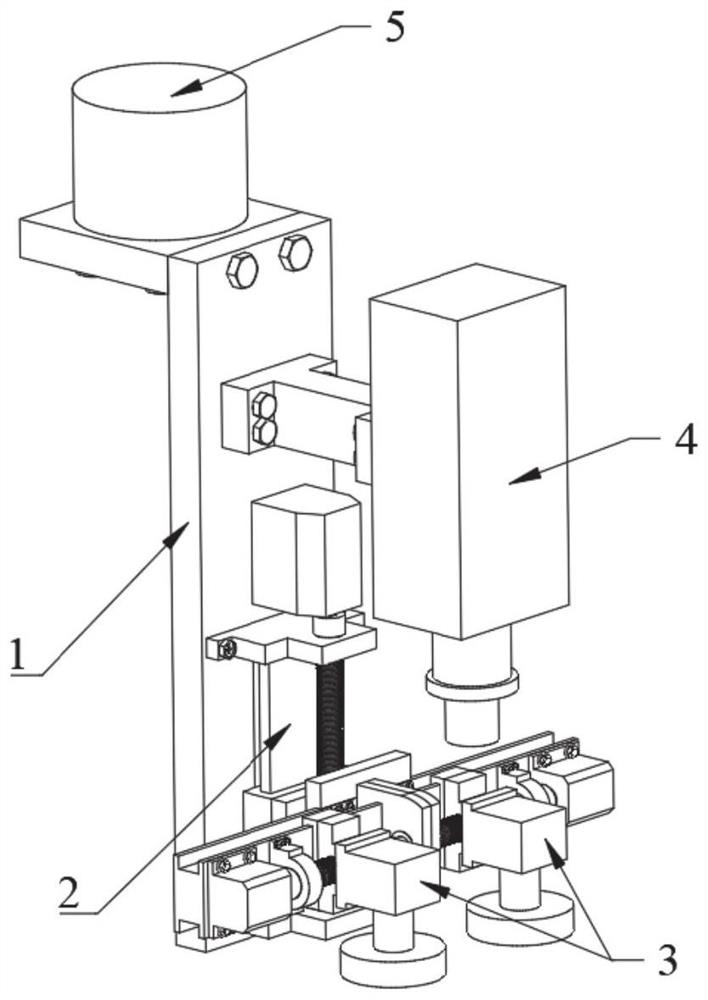

[0076] Taking the online rolling of square plate surface coating as an example, the coating online rolling device includes: fixture 1, ball screw module 2, double rolling unit 3, spray gun 4 and robot arm 5, used for thermal spray coating online rolling, such as figure 1 shown.

[0077] In this embodiment, the thermal spray coating is NiCr-Cr prepared by supersonic spraying technology. 3 C 2 Metal-ceramic coating, coating spraying 6-10 layers, single layer thickness 40-60μm;

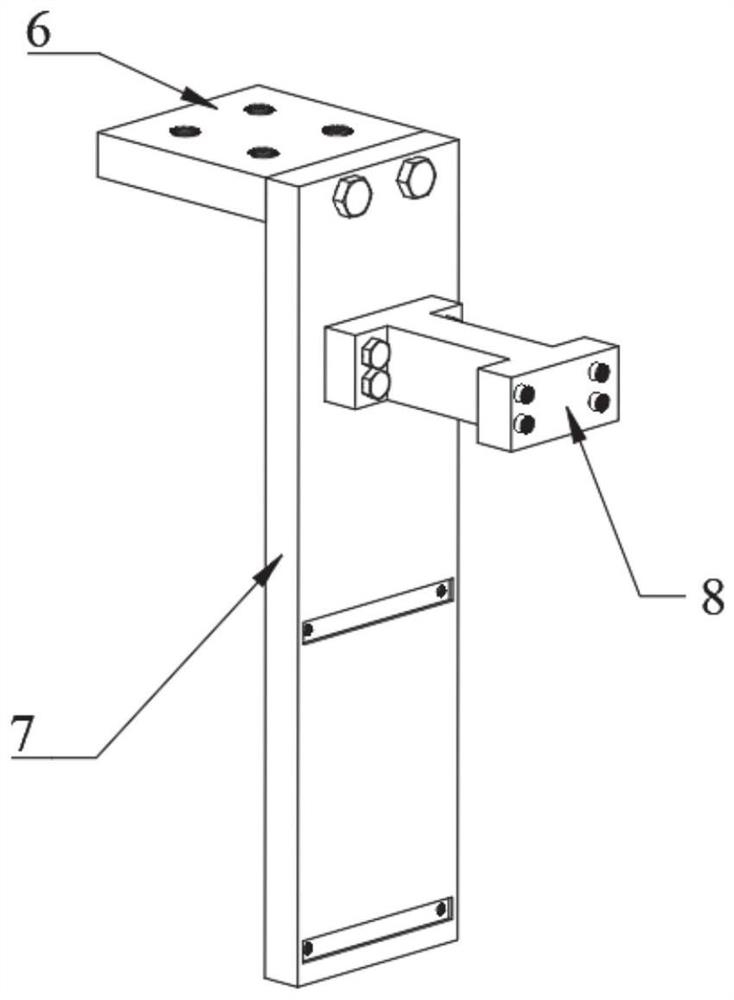

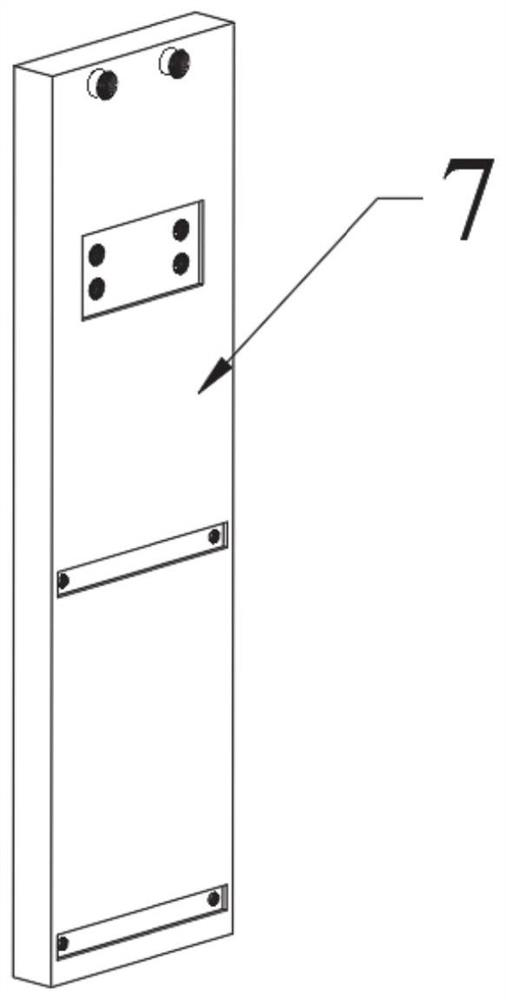

[0078] In this embodiment, the clamp 1 is connected by bolts, the upper part is connected to the robot arm 5, the middle part is connected to the spray gun 4, and the lower part is connected to the ball screw module 2, such as figure 2 , image 3 , Image 6 and Figure 7 shown;

[0079] In this embodiment, the ball screw module 2 includes a vertical ball screw module 11 and two horizontal ball screw modules 10 and 12, and the horizontal ball screw modules 10 and 12 pass through the fixing block 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com