Linear gravel dehydration device

A dehydration device, a linear technology, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve the problems of inability to further reduce, difficult to remove, etc. Guarantees the effect of squeezing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

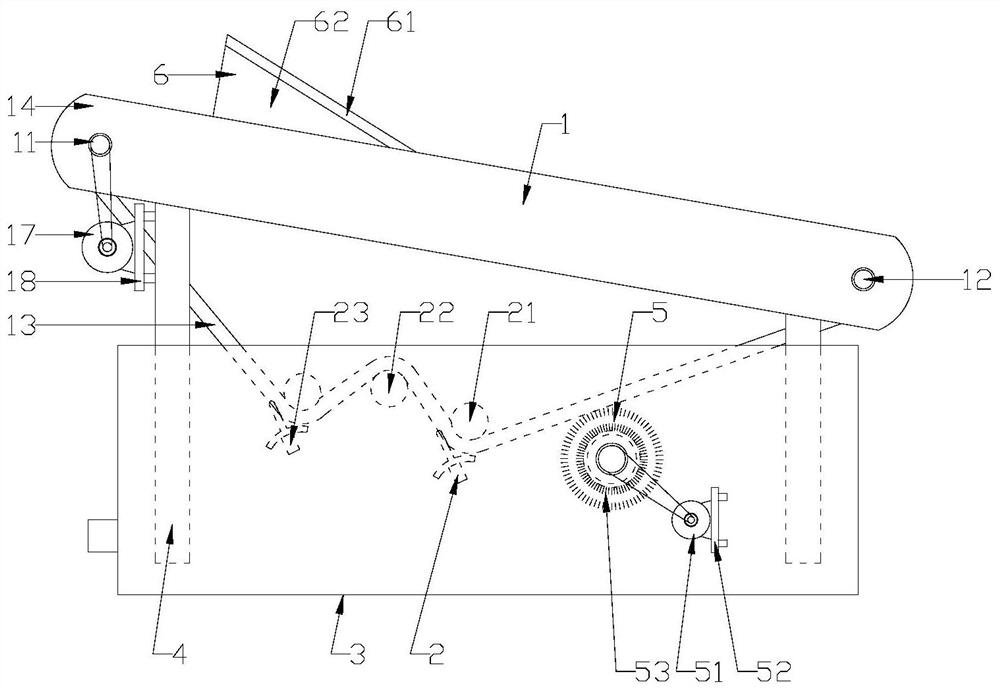

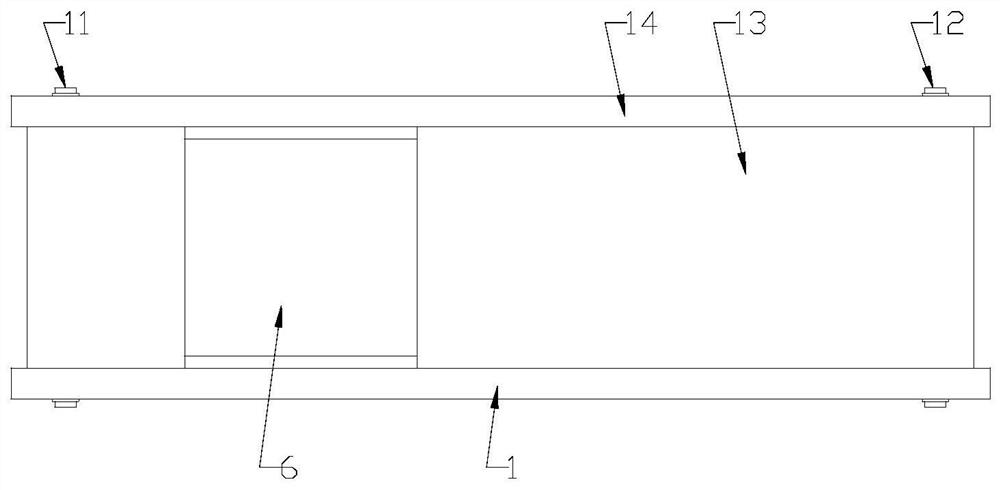

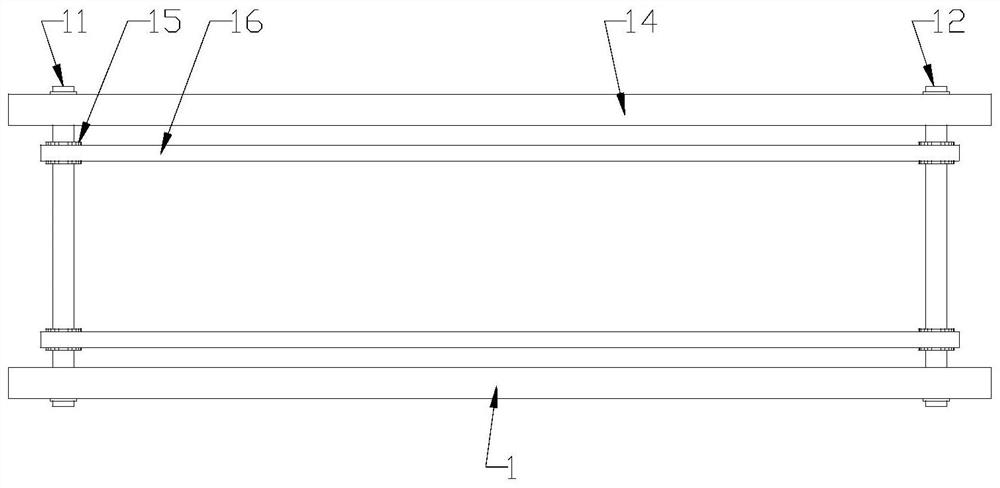

[0022] refer to Figure 1 to Figure 5 , a linear gravel dewatering device of the present invention, comprising a conveyor belt 1, a dehydration assembly 2, a water tank 3, legs 4, a brush 5 and a control device, the conveyor belt 1 is supported obliquely on the water tank 3 by several legs 4 Above, the dehydration assembly 2 includes a first guide roller 21, a second guide roller 22 and a presser 23, and several first guide rollers 21 and second guide rollers 22 are rotatably fixed in the water tank 3 through bearings respectively. One section of the moisture-absorbing belt body 13 of the conveyor belt 1 extends into the water tank 3 and is sequentially limited by the first guide roller 21 and the second guide roller 22 to form a wave band, and the presser 23 is fixed In the water tank 3 and press the hygroscopic belt 13 close to the first guide roller 21, the brush 5 is fixed in the water tank 3 and is located on the belt feeding side of the dehydration assembly 2, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com