High-precision portable inner taper hole grinding device

A portable, inner tapered hole technology, which is applied to the grinding drive device, grinding frame, grinding bed, etc., can solve the problems of processing efficiency and processing accuracy need to be improved, and achieve the improvement of grinding accuracy and grinding efficiency. , The effect of fast processing speed and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

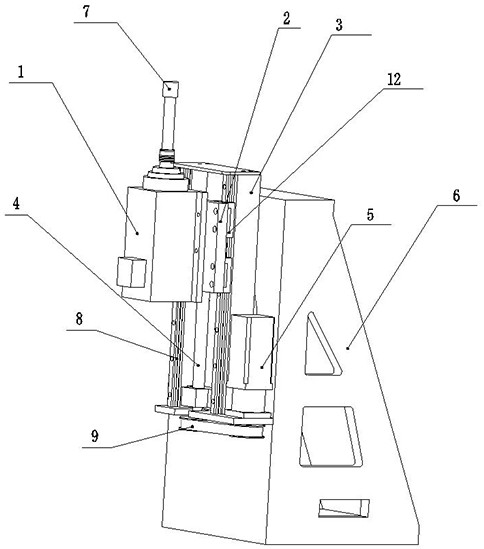

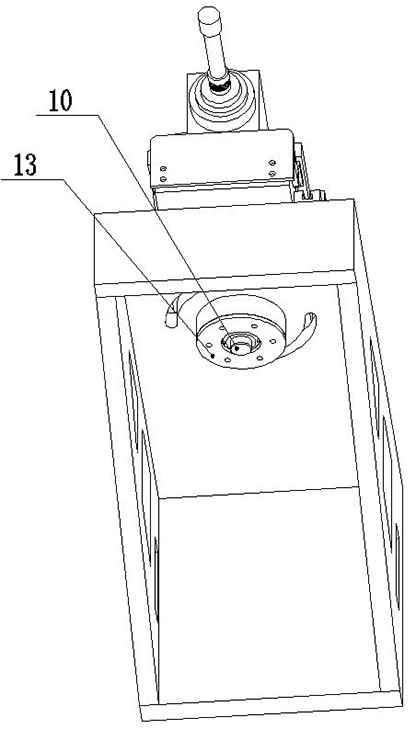

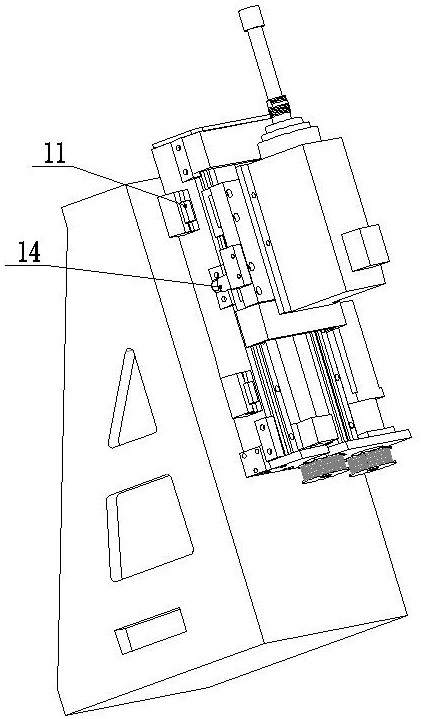

[0019] Such as figure 1 , a high-precision portable internal taper hole grinding device, including an electric spindle 1, an upper pallet 2, a lower pallet 3, a screw 4, a feed motor 5, a base 6, a grinding head 7, a guide rail 8, and a belt 9 , Central shaft 10, limit block 11, guide rail slider 12, bearing gland 13, limit switch 14. The lower supporting plate 3 is installed on the base 6 through the central shaft 10, the feed motor 5 is installed on the lower supporting plate 3, the electric spindle 1 with the grinding head 7 installed on the upper supporting plate 2, and the upper surface of the lower supporting plate 3 is installed There is a guide rail 8, the lower surface of the upper pallet 2 is installed on the guide rail slider 12, the feed motor 5 transmits power to the lead screw 4 through the belt 9, and drives the upper pallet 2 to slide on the guide rail 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com