Numerical control grinding machine for engine crankshaft

A CNC grinding machine and engine technology, applied in the direction of grinding machines, parts of grinding machine tools, and machine tools designed for grinding the rotating surface of workpieces, etc., can solve the problems of different grinding time, crankshaft machining accuracy, surface roughness and waviness of the machined surface Quality impact, different grinding force and other issues, to achieve the effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the present invention will be described below with reference to the drawings.

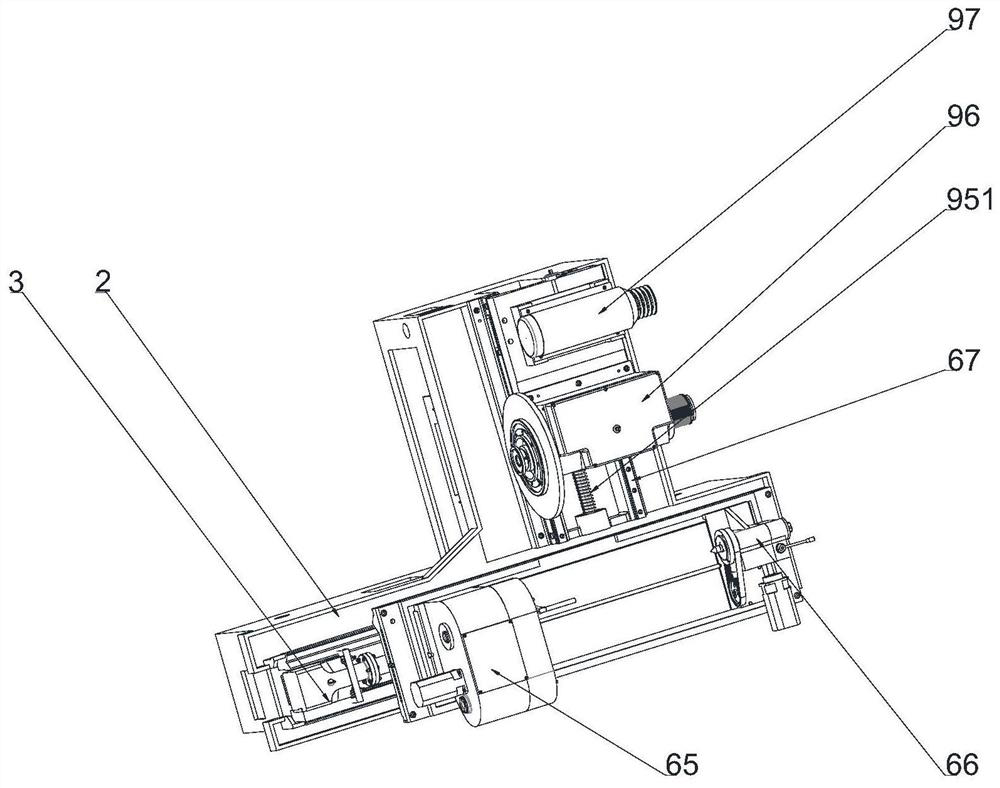

[0047] The present invention is made up of five parts, comprises bed base 2, longitudinal feeding system assembly 3, headstock assembly 65, tailstock assembly 66 and grinding wheel frame assembly 1. as attached figure 1 As shown: the bed base 2 is provided with a longitudinal feed system 3 and a backing plate 92 . The bed base 2 is connected to the longitudinal feed system 3 through the longitudinal ball screw 47, the wheel frame assembly 1 is connected to the backing plate 92 (arranged with the lateral feed system assembly), and the head frame assembly is connected to the guide rail of the upper workbench. Become 65, tailstock assembly 66.

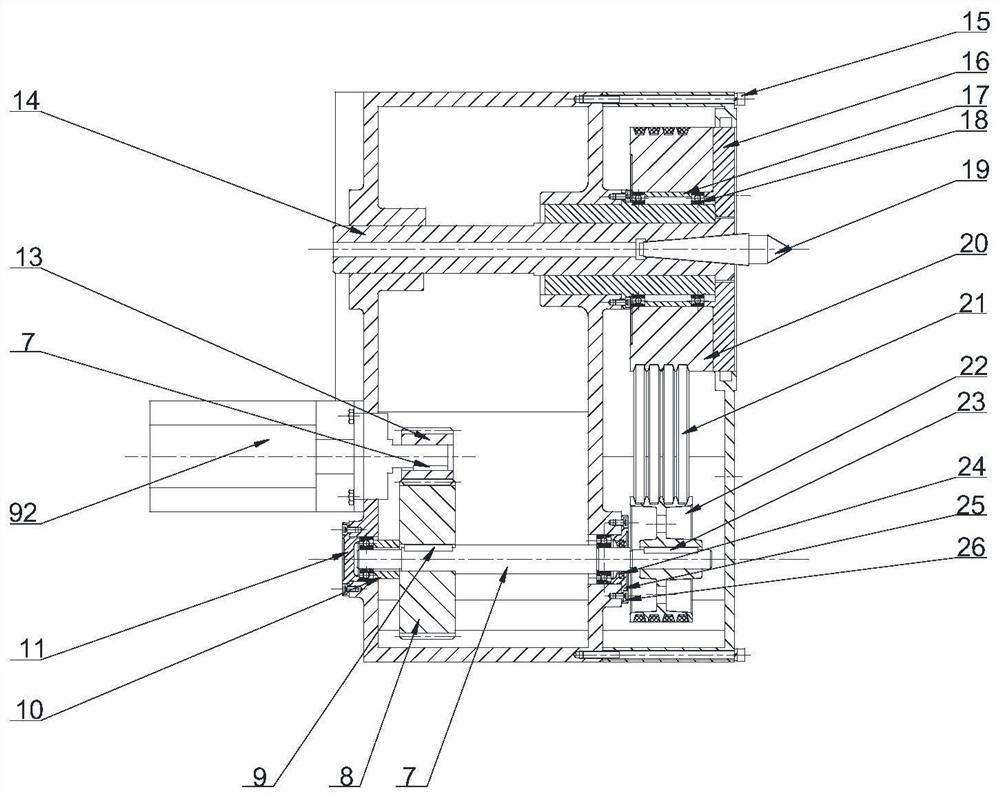

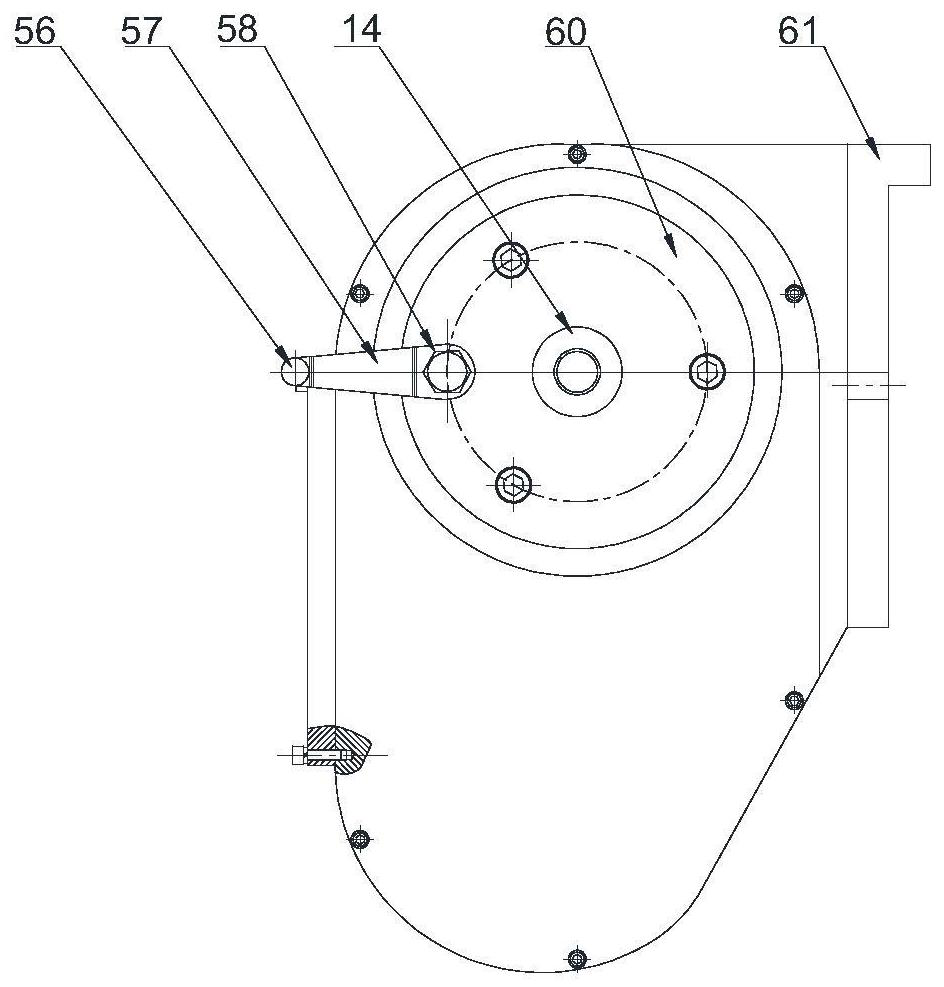

[0048] See figure 2 , image 3 : the AC servo motor 92 is fixed on the head frame box body 61 through bolts, the head frame driving rod 56 and the driving rod cover 57 are perpendicular to each other, the driving rod cover 57 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com