Corrugated board cutting production line and production method thereof

A corrugated cardboard, production line technology, applied in paper/cardboard containers, papermaking, containers, etc., can solve the problems of low degree of automation, health hazards of operators, and poor collection and processing of fibers and particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

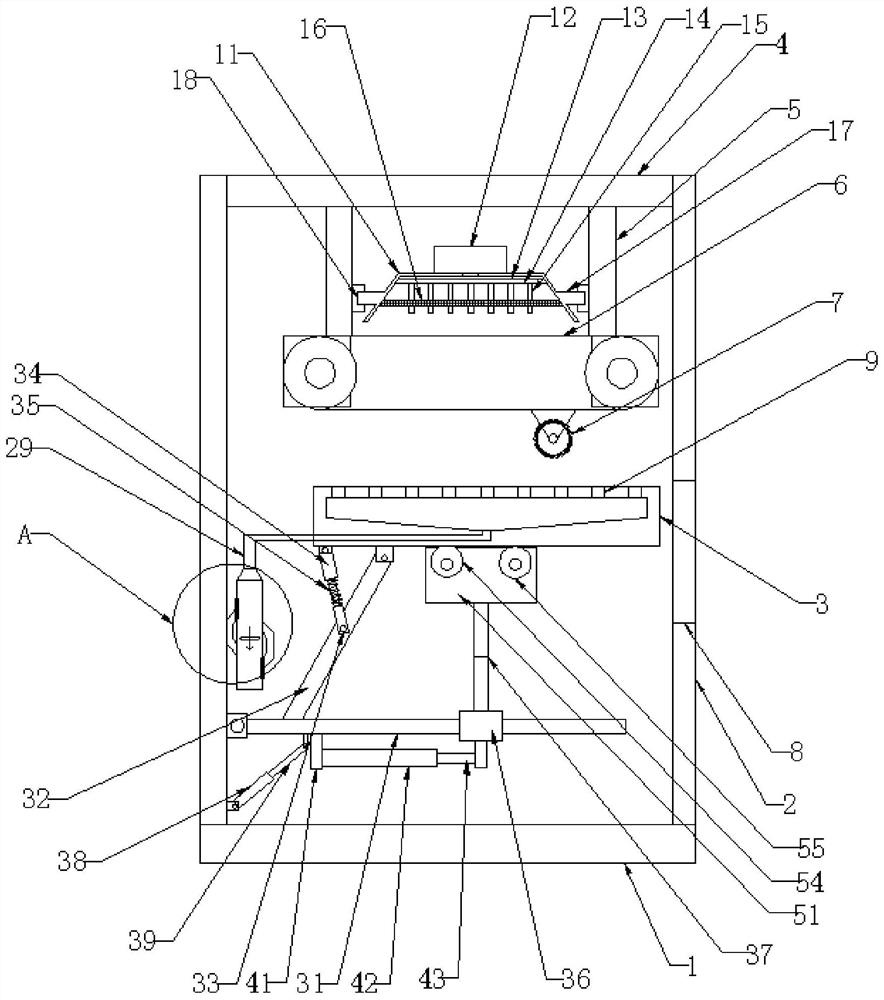

[0037] Such as figure 1 As shown, the present invention discloses a corrugated cardboard cutting production line, which includes a base 1 and two symmetrically arranged support frames 2 vertically fixed on the upper end surface of the base 1, and the two support frames 2 are fixedly connected with a placeable The cutting table 3 of corrugated cardboard and the positioning plate 4 of the positioning cutting assembly, the support frame 2 is provided with a discharge port 8, in a specific embodiment of the present invention, the cutting assembly includes two pieces arranged under the positioning plate 4 The cantilever bracket 5 on the surface and the motor arranged on one of the cantilever brackets 5, the motor shaft of the motor is provided with a driving wheel, and the other cantilever bracket 5 is provided with a driven wheel, and the driving wheel and the driven wheel are connected by a belt 6 transmission , the belt 6 is provided with a cutting knife assembly capable of cutt...

Embodiment 2

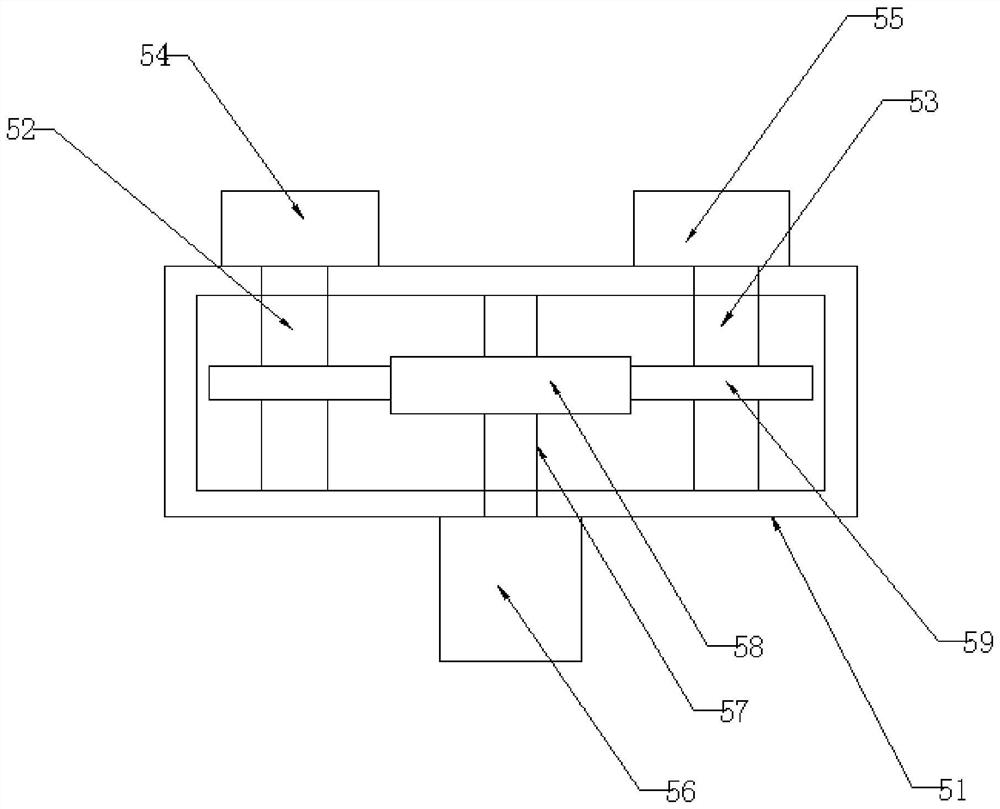

[0046] Such as Figure 1-Figure 3 As shown, the difference from Embodiment 1 is that, in a specific embodiment of the present invention, an inner cavity is provided inside the cutting table 3, and a number of air holes 9 communicating with the inner cavity are evenly arranged on the upper surface of the cutting table 3. , the inner cavity is connected with a control assembly for controlling the formation of negative pressure or positive pressure inside the inner cavity, and the support frame 2 is provided with a device for driving the cutting table 3 to rotate obliquely to the discharge port 8 and vibrate during the rotation. Vibration turns the assembly.

[0047] By adopting the above technical solution, during use, the corrugated cardboard is pushed onto the cutting table 3, at this time, the control component connected to the inner cavity controls the inner cavity to form a negative pressure, so that the lower surface of the corrugated cardboard is adsorbed through several ...

Embodiment 3

[0055] The present invention also discloses a production method suitable for the above-mentioned corrugated cardboard cutting production line. In a specific embodiment of the present invention, the following steps are included:

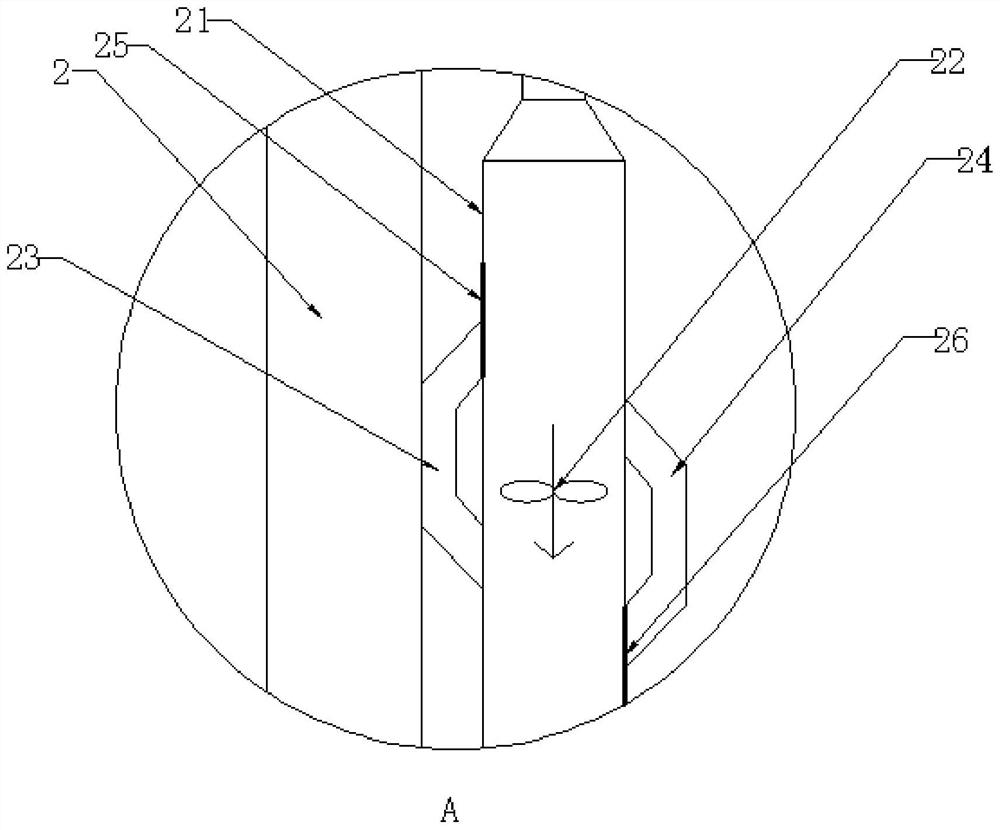

[0056] S1, fixed operation: the corrugated cardboard is pushed onto the cutting table 3, at this time, the controller controls the fan 22 to run, at this time, the main air duct 21 is switched to the first state, and the controller controls the first air door 25 to close the first air duct 23 and control the second damper 26 to close the lower port of the second air duct 24, under the operation of the blower fan 22, it extracts the air in the inner cavity through the hose 29 and discharges it through the main air duct 21, thereby Negative pressure is formed inside the inner cavity, and the lower surface of the corrugated cardboard is adsorbed and fixed through a number of air holes 9;

[0057] S2. Running cutting: After the corrugated cardboard is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com