A microbial sample pretreatment system

A microbiology and sample technology, applied in the field of microbiological sample pretreatment system, can solve the problems of personnel proficiency, different standardization of operation, influence on the accuracy of test results, increase of staff workload, etc., and achieve simple structure, convenient operation, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

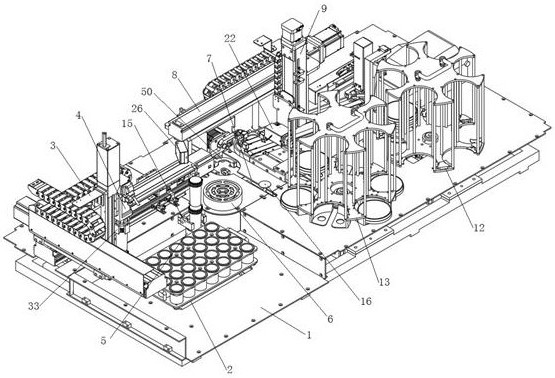

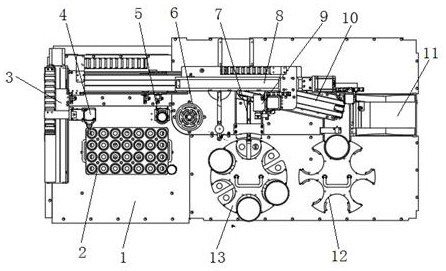

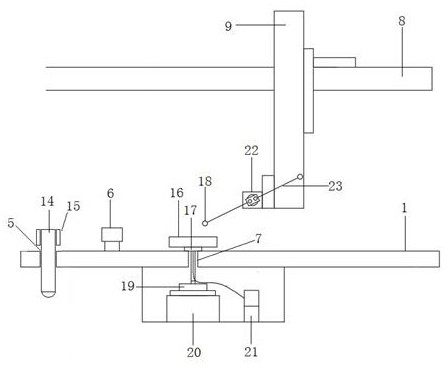

[0044] A microbial sample pretreatment system, comprising a workbench 1, an untreated petri dish compartment 13 and a controller 25, the workbench 1 is provided with a sample oscillation device 2 controlled by the controller 25, a sample tube clamping and cover opening Covering device, sterilizing device 6, scribing device, plate pushing and cap opening and closing device, automatic labeling device and petri dish storage device 12, in this embodiment, sterilizing device 6 is an infrared inoculating loop sterilizer.

[0045] Wherein: the device for pushing the plate, opening and buckling the cover and the automatic labeling device are all prior art, and a brief introduction is made here. The plate pushing and cap opening device is used in the microbial sample pretreatment system. It turns over the inverted culture dish and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com