Bearing steel and preparation method thereof

A bearing steel and molten steel technology, applied in the steel field, can solve the problems of shortening the initiation period of fatigue cracks, difficult deformation, and reducing bearing fatigue life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

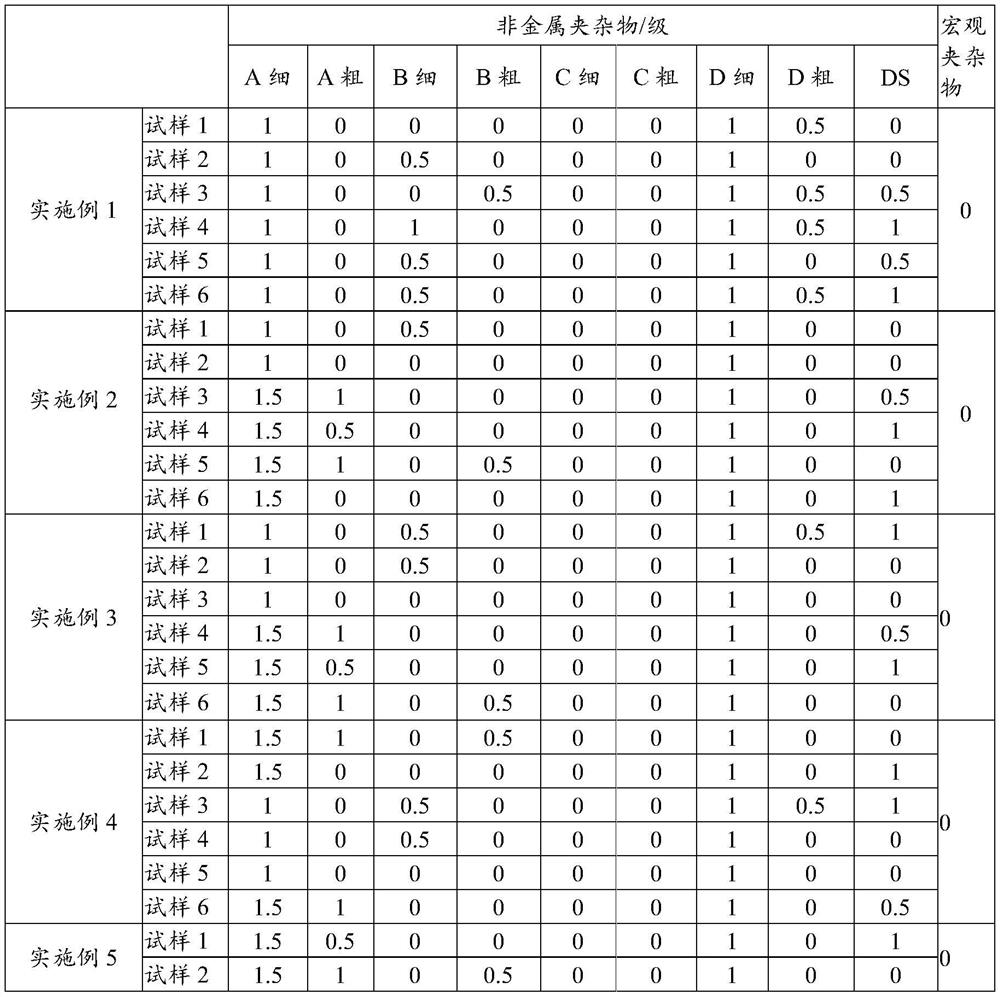

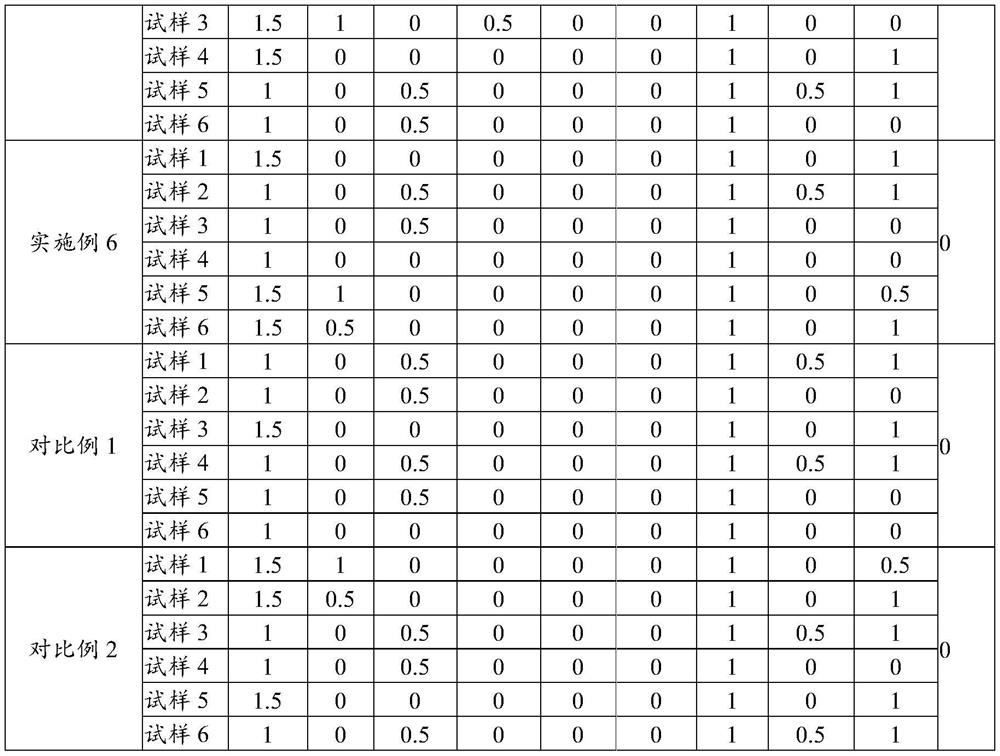

Examples

Embodiment 1

[0036] The present embodiment provides a kind of bearing steel, and its composition is listed in Table 1, and the preparation method of this bearing steel comprises the following steps:

[0037] (1) Converter smelting steps: During the tapping process of the converter, 120kg of effective aluminum is added to the molten steel to deoxidize the molten steel, and 800kg of steelmaking conditioner and 400kg of lime are added to slag.

[0038] (2) LF furnace refining step: when the LF furnace arrives at the station, add 404kg of lime; after the first sampling, adjust the Al content to 0.040%.

[0039] (3) RH vacuum degassing step: the processing time of the molten steel in an environment with a vacuum degree ≤ 266pa is 25 minutes, and the soft blowing time is 41 minutes.

[0040] (4) Continuous casting step: control the superheat of molten steel to 28°C, use 630A / 2.5Hz process conditions for electromagnetic stirring inside the crystallizer, and use 600A / 4Hz process conditions for ele...

Embodiment 2

[0042] The present embodiment provides a kind of bearing steel, and its composition is listed in Table 1, and the preparation method of this bearing steel comprises the following steps:

[0043] (1) Converter smelting steps: During the tapping process of the converter, 120kg of effective aluminum is added to the molten steel to deoxidize the molten steel, and 800kg of steelmaking conditioner and 400kg of lime are added to slag.

[0044] (2) LF furnace refining step: when the LF furnace arrives at the station, add 414kg of lime; after the first sampling, adjust the Al content to 0.040%.

[0045] (3) RH vacuum degassing step: the processing time of the molten steel in an environment with a vacuum degree ≤ 266pa is 25 minutes, and the soft blowing time is 34 minutes.

[0046] (4) Continuous casting step: control the superheat of molten steel to 32°C, use 630A / 2.5Hz process conditions for electromagnetic stirring inside the crystallizer, and use 600A / 4Hz process conditions for ele...

Embodiment 3

[0048] This embodiment provides a bearing steel whose composition is listed in Table 1. The preparation method of the bearing steel is the same as that of the bearing steel in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com