Construction method of foundation pit cover plate and support system

A construction method and a cover technology, which are applied in basic structure engineering, excavation, construction, etc., can solve the problems of low mechanical operation rate, high construction cost, long construction period, etc., achieve short construction period and improve resistance to earthwork extrusion Ability, effect of high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

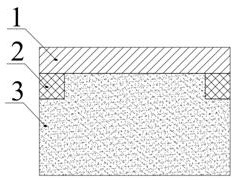

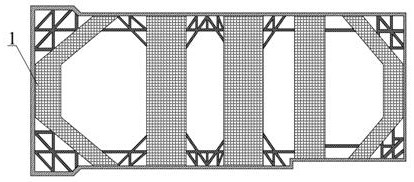

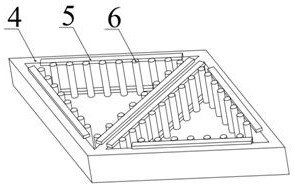

[0039] as attached figure 1 , attached figure 2 And attached image 3 This embodiment shows a construction method for foundation pit cover and support system. As an important auxiliary construction component in the construction process of a subway station, the cover has high quality requirements. The main uses of the cover are stacking materials, traffic passage, Cranes, pump trucks, and earthwork trucks are parked. For foundation pits with a length greater than 535.5m and a width of 71.4m to 80m, the construction load is considered to be a uniform load of 20kPa, and the thickness of the reinforced concrete cover 1 is 350mm. Double-layer two-way C25@150 Main tendon.

[0040] Under the action of a uniformly distributed load of 20kpa, the maximum bending moment and shear force of the first reinforced concrete support 2 under the reinforced concrete cover plate 1 reach 1248 kN m at the mid-span, and 2475 kN at the support m, the maximum shear force value reaches 684 kN. Acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com