Garbage incinerator used for garbage power generation and using method thereof

A technology for waste incinerators and waste-to-power generation, which is applied in combustion methods, incinerators, biochemical equipment and methods, etc., can solve problems such as low efficiency and incomplete waste incineration, and achieve the goal of ensuring safety, improving power, and ensuring environmental protection performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those of ordinary skill in the art can implement it after referring to this specification.

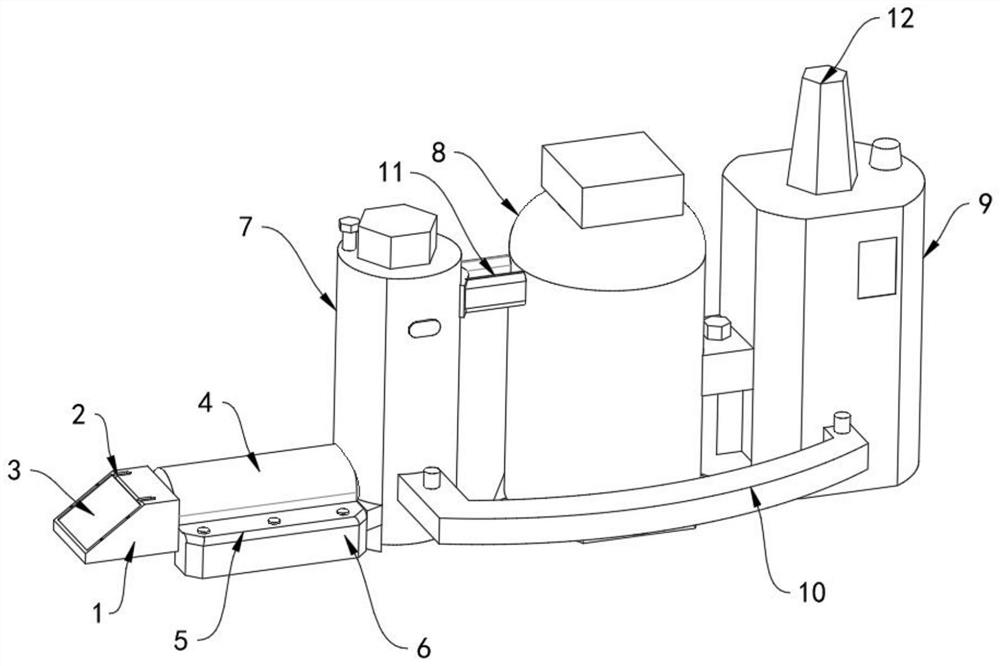

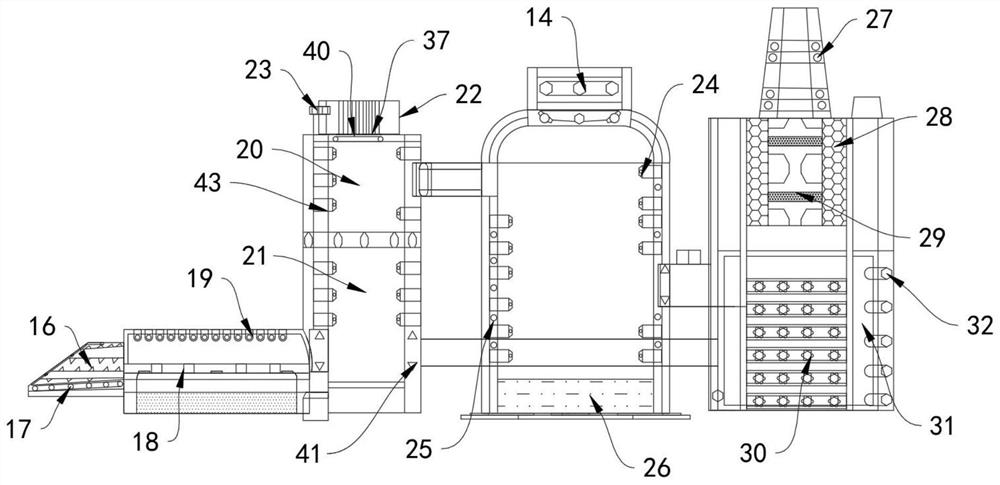

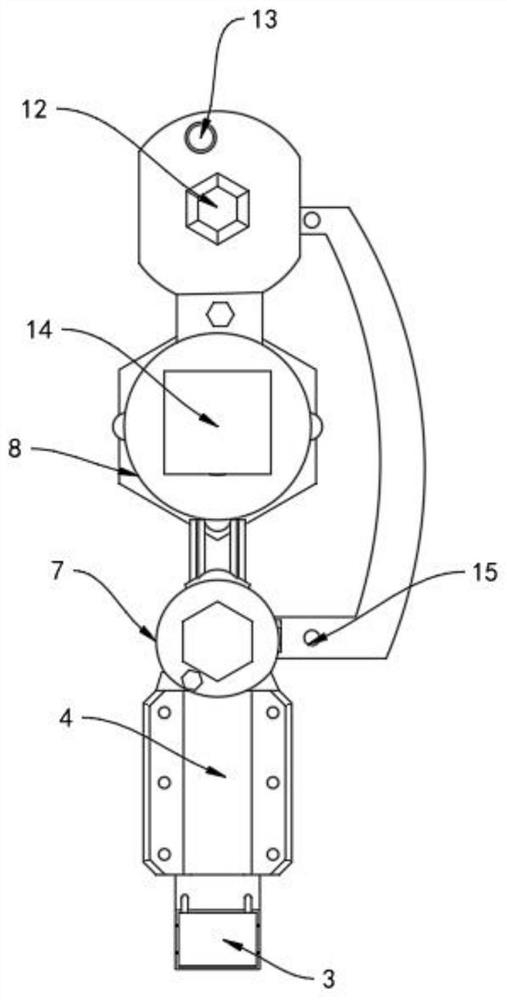

[0038] Such as Figure 1-5 As shown, a waste incinerator for waste power generation includes: a material guide structure 1, and a pre-processing structure 4 arranged on one side of the material guide structure 1; a fermentation tank 6, which is arranged on the pre-processing structure 4, the surface of the fermentation tank 6 is provided with a flip structure 5, and the flip structure 5 is fixedly connected to the surface of the fermentation tank 6; an incineration treatment structure 7 is arranged on one side of the expected treatment structure 4; heating drive Structure 8, which is arranged on one side of the incineration treatment structure 7, a connecting pipe 11 is installed at one end of the heating driving structure 8, and the connecting pipe 11 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com