Wide-area order tracking method and system for monitoring train running gear

A technology of order tracking and running parts, which is applied in the direction of railway vehicle testing, measuring ultrasonic/sonic/infrasonic waves, measuring devices, etc., can solve problems such as difficulty, large error, large cost of frequency multiplier, etc., to achieve reduction The effect of installation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the specific embodiments shown in the accompanying drawings, but these embodiments do not limit the present invention, those of ordinary skill in the art make structural, method, or functional changes based on these embodiments All are included in the scope of protection of the present invention.

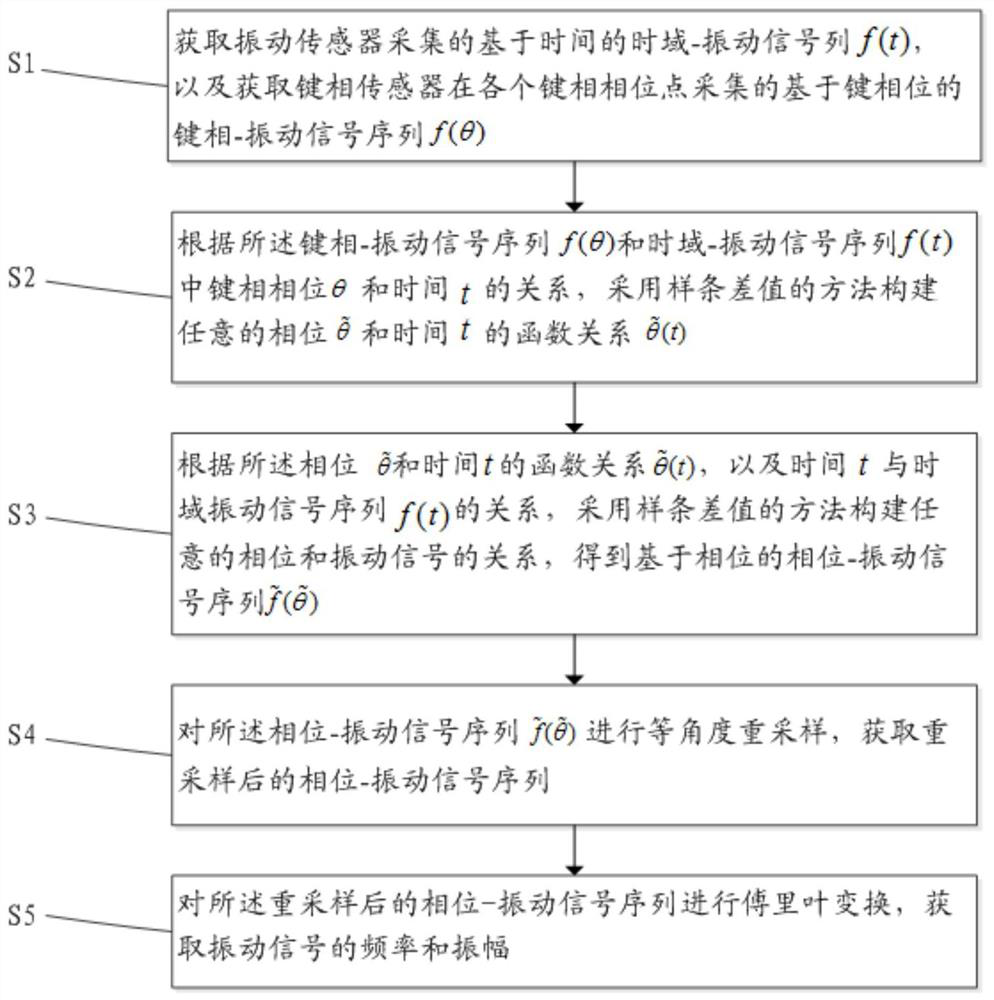

[0043] Such as figure 1 One embodiment of the present invention is shown, and the present invention provides a wide-area order tracking method for monitoring the running part of a train, the method comprising:

[0044] S1. Obtain the time-based time domain-vibration signal sequence f(t) collected by the vibration sensor, and obtain the key phase-vibration signal sequence f(θ) based on the key phase collected by the key phase sensor at each key phase point;

[0045] S2. According to the relationship between the key phase phase θ and time t in the key phase-vibration signal sequence f(θ) and the time d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com