Soft boiled egg preservative and application thereof in preparation of soft boiled eggs

A technology of soft-boiled eggs and preservatives, which is applied in the fields of application, egg preservation, food preservation, etc. It can solve the problems of coliform contamination of soft-boiled eggs, the inability to guarantee the initial microbial sterility level, and reduce the shelf life of soft-boiled eggs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of soft-boiled egg preservative, comprising the steps of:

[0035] According to the mass percentage of each component, 10% of glucose oxidase, 23% of protein glutaminase, 12% of phospholipase, 20% of citric acid and 35% of sodium citrate are uniformly mixed to obtain the soft-boiled egg preservative.

Embodiment 2

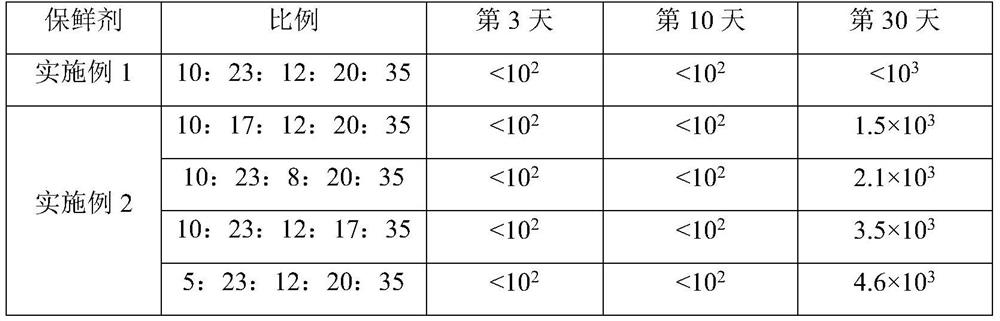

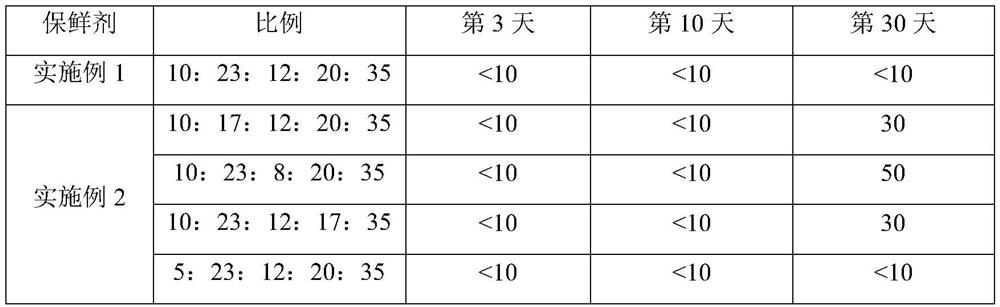

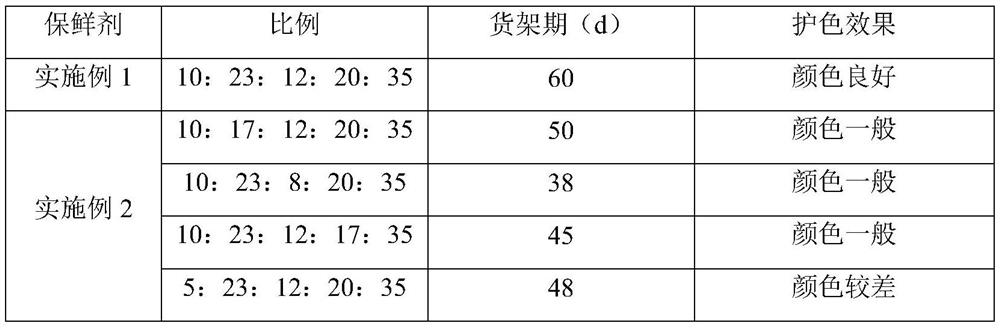

[0036] Example 2 Optimization of the dosage of preservative for soft-boiled eggs

[0037] Adjust the quality ratio of glucose oxidase, protein glutaminase, phospholipase, citric acid, and sodium citrate in Example 1 as shown in Table 1, and keep the others consistent with Example 1 to obtain the preservative for soft-boiled eggs.

Embodiment 3

[0039] A processing technology for soft-boiled eggs, comprising the steps of:

[0040] (1) After cleaning the surface of fresh eggs, boil them in a boiling water bath (98°C) for 6 minutes;

[0041] (2) Cool the boiled eggs obtained in step (1) in water at 10°C, peel off the shells and select eggs with no cracks on the surface and no protein loss, place the peeled eggs in water, and refrigerate at 4°C for 2 hours;

[0042] (3) Preparation of marinade: 100 parts of purified water, 3 parts of salt, 5 parts of white sugar, 0.8 parts of cooking wine, 4 parts of dark soy sauce, 0.8 parts of star anise, 1.8 parts of cinnamon, 1.2 parts of ginger, 1.8 parts of fennel, 1.6 parts of licorice part, soft-boiled egg preservative, heated for 30 minutes, and cooled to obtain marinade; wherein the amount of soft-boiled egg preservative is 0.2% of the marinade mass;

[0043] (4) Put the peeled egg obtained in step (2) into a packaging bag, and add the marinade prepared in step (3) at a ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com