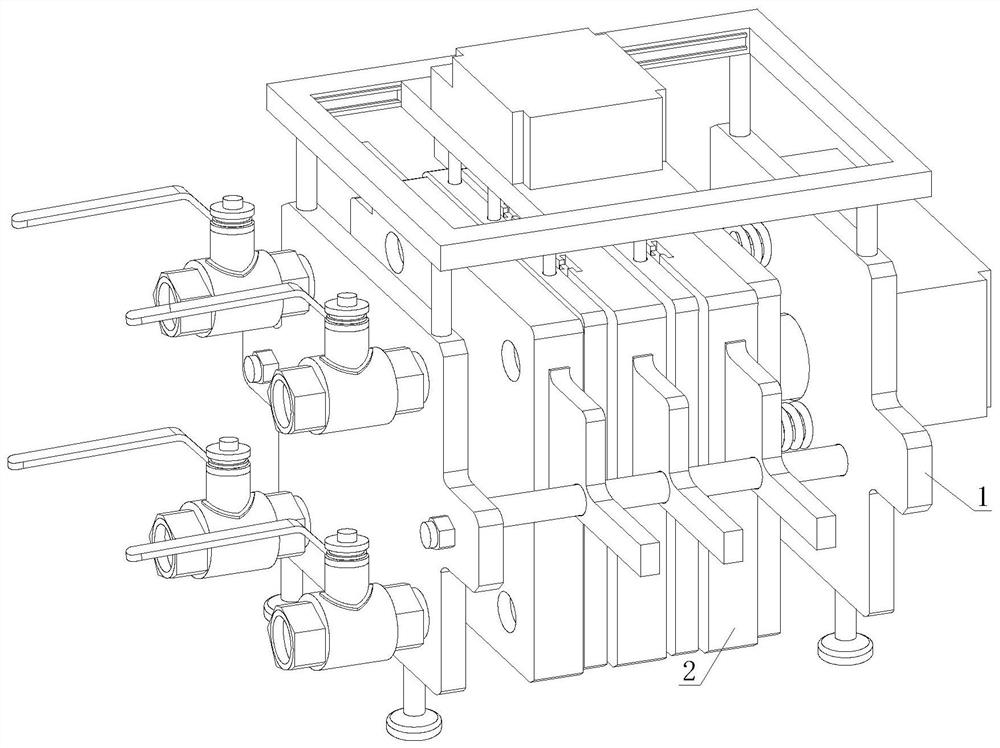

Crystal liquid filter pressing device for ammonium paratungstate production and processing and implementation method thereof

An ammonium paratungstate and hydraulic technology, which is applied in the field of crystal hydraulic filtration devices for the production and processing of ammonium paratungstate, can solve the problems of poor pressure filtration and insufficient filtration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0038] In order to better demonstrate the implementation process of a crystal hydraulic filter device for ammonium paratungstate production and processing, this example now proposes a method for implementing a crystal hydraulic filter device for ammonium paratungstate production and processing, including the following steps:

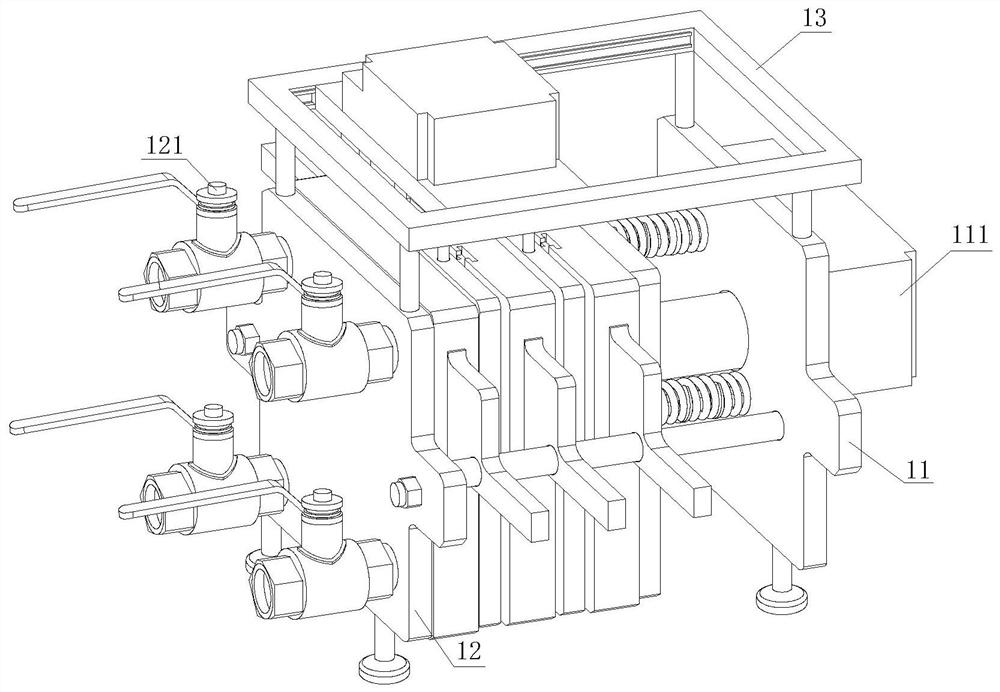

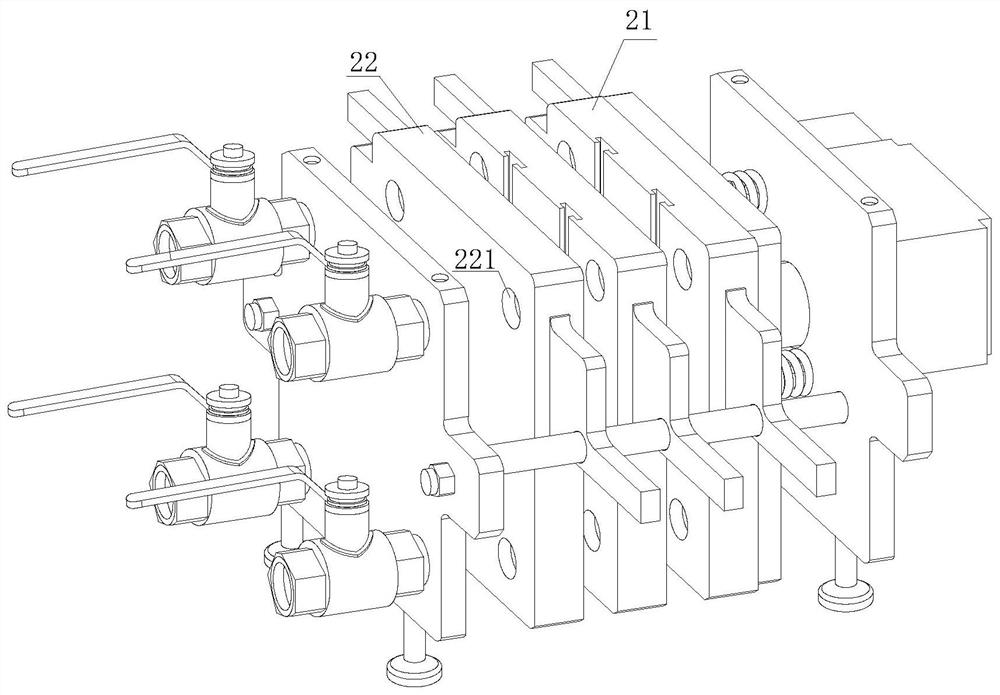

[0039] Step 1: start the hydraulic cylinder 111, drive the jack rod 1111 of the cylinder to shrink inwardly, and put the ammonium paratungstate flake crystals to be processed between the separated adjacent diaphragm frame 21 and filter plate 23;

[0040] Step 2: Start the hydraulic cylinder 111 again, drive the jack rod 1111 of the cylinder to elongate in the horizontal direction, and use the push plate 11111 to slowly contact and press the diaphragm plate frame 21 near one end thereof;

[0041] Step 3: Continuously press the diaphragm frame 21 at its adjacent end through the diaphragm frame 21, and continuously drive the cylinder ejector rod 1111 to sque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com