Method for preparing zirconia hollow film by microfluidic control

A zirconium dioxide and microfluidic system technology is applied in the field of preparation of ceramic films to achieve the effects of uniform distribution, high synthesis efficiency and uniform film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Steps include:

[0040] (1) Material preparation

[0041] External phase: surfactant Span 80 (1.5wt%), 0.25vol% tetramethyldiethylamine (TMEDA) is added in the silicone oil; Above-mentioned Span 80 and tetramethyldiethylamine are the final concentrations in the silicone oil ;

[0042] Intermediate phase: zirconium sol precursor: zirconium gel precursor is composed of 2.5mol / L zirconium oxychloride (ZrOCl 2 ) aqueous solution, 4.5mol / L urea (CON 2 H 4 ), 0.8mol / L citric acid (C 6 H 8 O, ), 10wt% polyethylene (PVA) was mixed in a volume ratio of 2:3:0.8:1.5, followed by adding 2.66g of yttrium nitrate (Y(NO) 3 ) 3 ·6H 2 O), the mixture was heated to 90 °C and slowly stirred to 30 mL; then 0.10 μmol / L pH probe-carboxyfluorescein 2',7'-bis(2-carboxyethyl)-5(6)-carboxyfluorescein (BCECF) was added to the sol in the composition;

[0043] Internal phase: 60g molten paraffin (melting point 27°C);

[0044] (2) Preparation of gel film

[0045] Use a syringe pump to pa...

Embodiment 2

[0054] Steps include:

[0055] (1) Material preparation

[0056] External phase: silicone oil and surfactant Span 80 (1wt%), 0.125vol% tetramethyldiethylamine (TMEDA) is added in the silicone oil;

[0057] Intermediate phase: zirconium sol precursor: zirconium gel precursor is composed of 2mol / L zirconium oxychloride (ZrOCl 2 ) aqueous solution, 4mol / L urea (CON 2 H 4 ), 0.5mol / L citric acid (C 6 H 8 O), 8wt% polyethylene (PVA) were mixed in a volume ratio of 2:3:0.8:1.5, followed by adding 1.33g of yttrium nitrate (Y(NO) 3 ) 3 ·6H 2 O), the mixture was heated to 90 °C and slowly stirred to 22 mL; then 0.09 μmol / L pH probe-carboxyfluorescein 2',7'-bis(2-carboxyethyl)-5(6)-carboxyfluorescein (BCECF) was added to the sol constitute;

[0058] Internal phase: 50g molten paraffin (melting point 27°C);

[0059] (2) Preparation of gel film

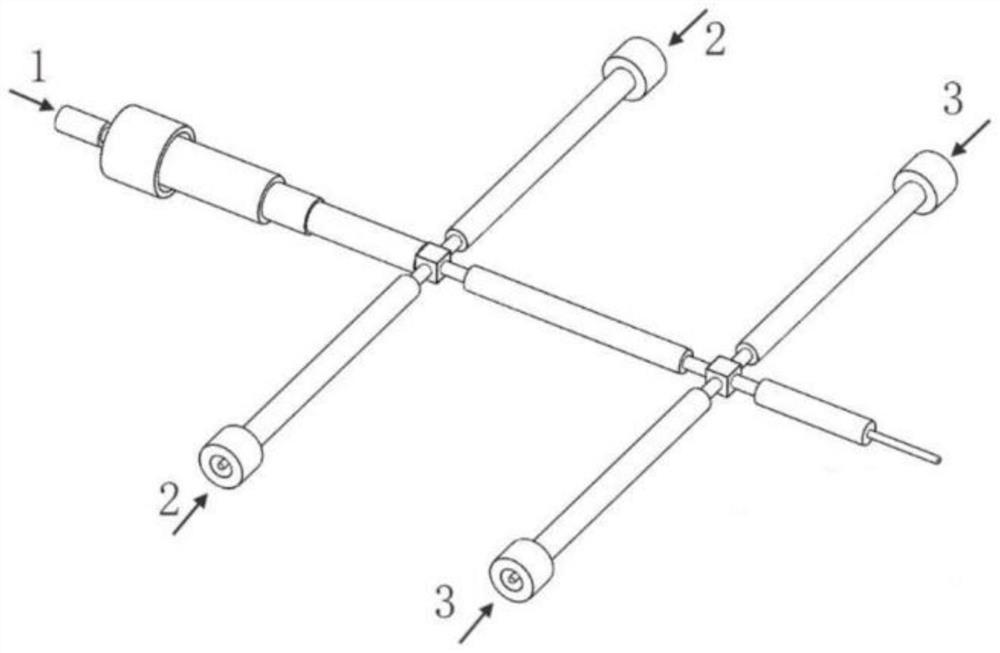

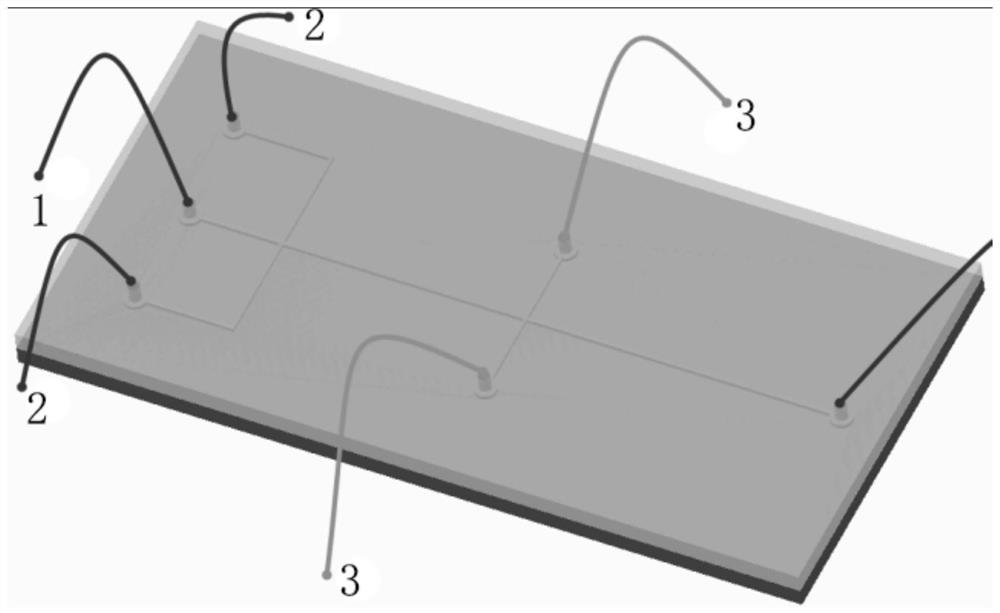

[0060] Use a syringe pump to pass the material into the channels of the microfluidic system described in the appendix. figure 1 As s...

Embodiment 3

[0069] Steps include:

[0070] (1) Material preparation

[0071] External phase: 2wt% surfactant Span 80, 0.25vol% tetramethyldiethylamine (TMEDA) is added in the silicone oil; Above-mentioned Span 80 and tetramethyldiethylamine are the final concentrations in the silicone oil;

[0072] Intermediate phase: zirconium sol precursor: zirconium gel precursor is composed of 2.5mol / L zirconium oxychloride (ZrOCl 2 ) aqueous solution, 4.5mol / L urea (CON 2 H 4 ), 0.8mol / L citric acid (C 6 H 8 O, ), 10wt% polyethylene (PVA) was mixed in a volume ratio of 2:3:0.8:1.5, followed by adding 2.66g of yttrium nitrate (Y(NO) 3 ) 3 ·6H 2 O), the mixture was heated to 90 °C and slowly stirred to 30 mL; then 0.10 μmol / L pH probe-carboxyfluorescein 2',7'-bis(2-carboxyethyl)-5(6)-carboxyfluorescein (BCECF) was added to the sol in the composition;

[0073] Internal phase: 58g molten paraffin (melting point 27°C);

[0074] (2) Preparation of gel film

[0075] Use a syringe pump to pass mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com