Purification method of N-(2-aminoethyl)-N-ethyl m-toluidine

A purification method and technology of toluidine, applied in amino compound purification/separation, organic chemistry, etc., can solve the problems of high equipment requirements for purification, harsh conditions for purification, etc., and achieve the effect of reducing difficulty and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

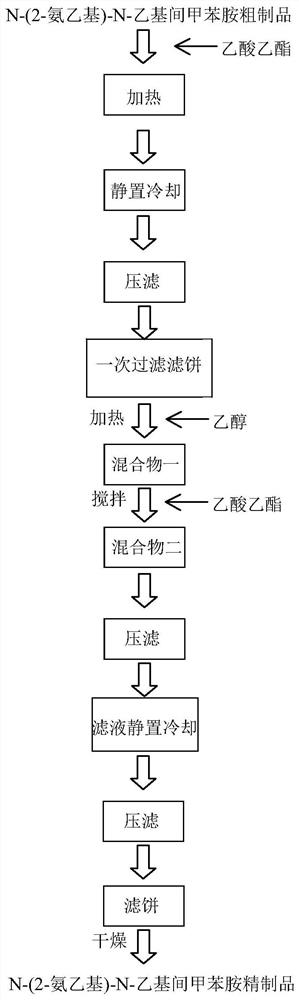

Image

Examples

preparation example 1

[0042] Preparation method: Add 0.1mol (13.52g) N-ethyl-m-toluidine, 0.11mol (22.54g) 2-bromoethylamine hydrobromide to a 250mL three-necked flask equipped with a thermometer, condenser and magnetic stirrer Salt, 0.07mol (7g) calcium carbonate and 7.5ml water, then stir the material in the flask at a speed of 300r / min, and raise the temperature to 140°C, reflux for 4h, and then naturally cool to room temperature to obtain a purity of 92.70%N - 50.2 g of crude product of (2-aminoethyl)-N-ethyl-m-toluidine.

preparation example 2

[0044]Preparation method: Add 0.1mol (13.52g) N-ethyl-m-toluidine, 0.11mol (22.54g) 2-bromoethylamine hydrobromide to a 250mL three-necked flask equipped with a thermometer, condenser and magnetic stirrer Salt, 0.07mol (7g) calcium carbonate and 7.5ml water, then stir the material in the flask at a speed of 300r / min, and raise the temperature to 140°C, reflux for 4h, and then naturally cool to room temperature to obtain a purity of 90% N - 50 g of a crude product of (2-aminoethyl)-N-ethyl-m-toluidine.

preparation example 3

[0046] Preparation method: Add 0.1mol (13.52g) N-ethyl-m-toluidine, 0.11mol (22.54g) 2-bromoethylamine hydrobromide to a 250mL three-necked flask equipped with a thermometer, condenser and magnetic stirrer Salt, 0.07mol (7g) calcium carbonate and 7.5ml water, then stir the material in the flask at a speed of 300r / min, and raise the temperature to 140°C, reflux for 4h, and then naturally cool to room temperature to obtain a purity of 93% N - 49.5 g of crude product of (2-aminoethyl)-N-ethyl-m-toluidine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com