Glycosylated protein preparation method based on deep eutectic solvent

A glycosylated protein and deep eutectic solvent technology, which is applied in the field of protein processing, can solve the problems of poor emulsification ability and emulsification stability of glycoproteins, and achieve the effects of good emulsification activity, improved functional properties, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

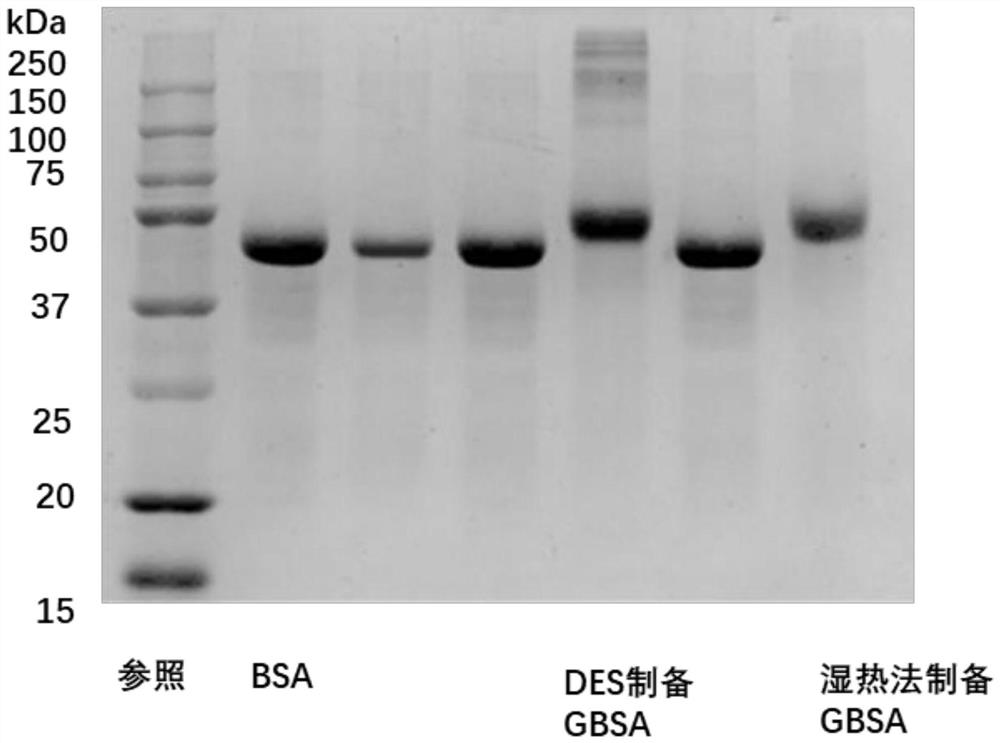

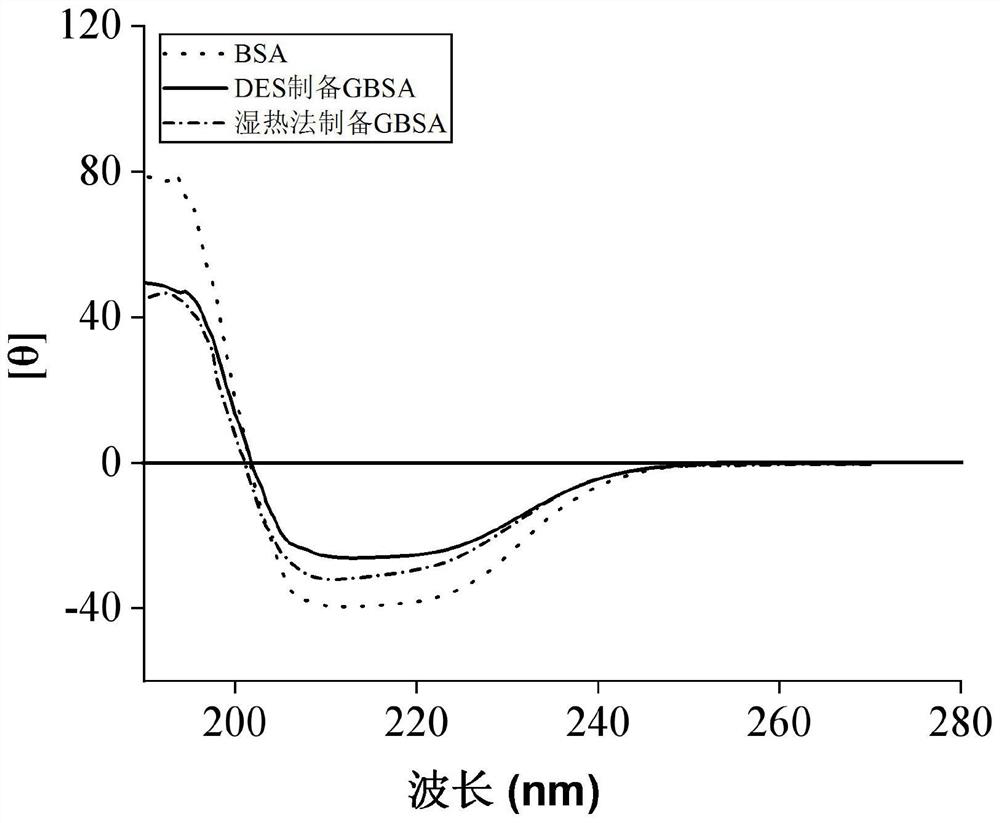

[0037] A method for preparing glycoprotein with a deep eutectic solvent, through the following process steps:

[0038] S1. Preparation of deep eutectic solvent: Mix choline chloride and glucose (Glucose, G) with a molar mass ratio of 1:1 in a beaker, stir at 200 rpm, and incubate in an oil bath at 90°C for 5 hours to obtain a uniform Transparent deep eutectic solvent (DES);

[0039] S2. Preparation of glycosylated protein: Dilute the DES prepared in S1 with PBS (0.01M, pH=7) into a 60% (w / w) DES solution, and mix thoroughly with a vortex mixer; then dilute the diluted DES The solution (5g) was incubated with bovine serum albumin (BSA, 0.25g) in an oil bath at 100°C for 2 hours to obtain glycosylated bovine serum albumin (GBSA);

[0040] S3. Preparation of glycosylated protein by traditional wet heat method (control group): Dilute 2.82g of glucose with 2mL of PBS (0.01M, pH=7), mix thoroughly; then mix with 0.25g of BSA, and place in an oil bath at 100°C Incubate for 2 hours to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emulsion stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com