Polypropylene composition special for automobile hard plastic blasting instrument board and preparation method thereof

A polypropylene composition and composition technology, applied in the field of polypropylene materials, can solve the problems of poor rigidity and toughness balance of polypropylene materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

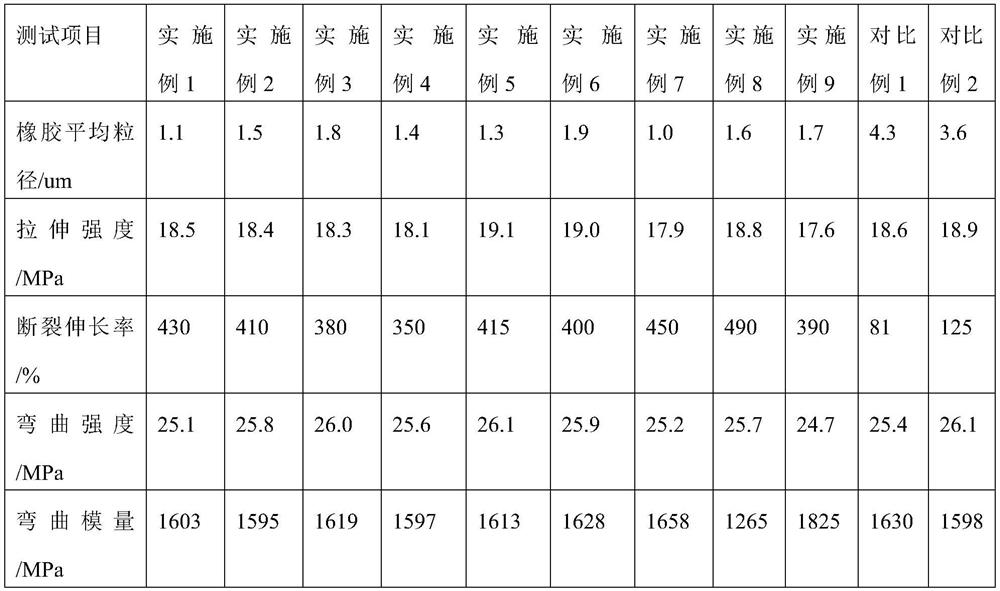

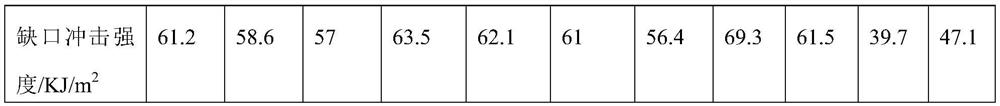

Examples

Embodiment 1

[0033] This embodiment provides a polypropylene composition for automotive hard plastic blasting instrument panels and a preparation method thereof. The composition includes the following raw materials in parts by weight: 54 parts of polypropylene PP M2600R, 20 parts of elastomer POE 8842, and ionic polymer Surlyn 5 parts of 8920, 20 parts of talc powder TYT-899, 0.25 parts of hindered phenolic primary antioxidant Irganox 1010, 0.25 parts of phosphite secondary antioxidant Irganox 168, 0.3 parts of hindered amine light stabilizer 770, stearic acid Zinc ZN-ST 0.2 parts.

[0034] The preparation method of above-mentioned composition is:

[0035] (1) After mixing 20 parts of elastomer POE 8842, 54 parts of polypropylene PP M2600R and 0.1 part of azobisisobutyronitrile AIBN, under the action of an initiator, chemically react in the first-stage twin-screw extruder, get the material;

[0036] (2) Physically blending other raw materials according to parts by weight with the materia...

Embodiment 2

[0039] According to Example 1, this example provides a polypropylene composition for automotive hard plastic blasting instrument panels and a preparation method thereof, except that the initiator is benzoyl peroxide BPO, the rest are the same as Example 1.

Embodiment 3

[0041] According to Example 1, this example provides a polypropylene composition for automotive hard plastic blasting instrument panels and a preparation method thereof, except that the initiator is dicumyl peroxide DCP, and the others are the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com