Photoelectric signal switching connector

A technology for switching connectors and optoelectronic signals, which is applied in the direction of connection, parts and circuits of connecting devices, and can solve the problems of inability to meet the requirements of miniaturization of equipment and use in harsh environments, poor strength and stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

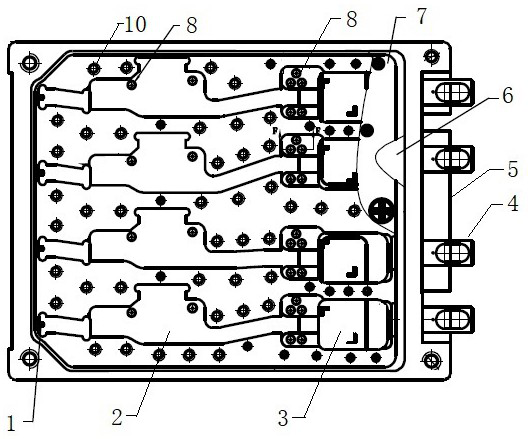

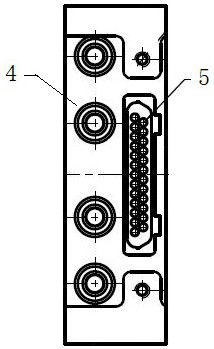

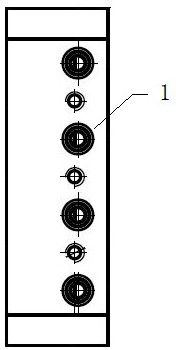

[0032] Such as Figure 1-11 , a photoelectric signal transfer connector, including a box body, an electrical connector 1 and an optical connector 4, the box body is made of metal, and a conversion cavity and a control cavity are arranged on the box body, and the conversion cavity A converter installation position is provided, a conversion controller is provided in the control chamber, a glass-sealed welding pin 8 is provided between the conversion chamber and the control chamber, and the bottom surface of the converter installation position is provided with a The heat conduction block 9 on the outside of the box body, and the control connector 5 is also provided on the box body. The material of the heat conduction block 9 is tungsten copper, and the material of the box body is copper. After the surface of the box body is electroplated with nickel, it is welded with the heat conduction block 9 by silver-copper solder, and then the surface is plated with gold.

[0033] Such as ...

Embodiment 2

[0040] The leakage rate of said electrical connector 1 in the connector is lower than 1X10 -3 Pa.cm 3 / S. The insulation resistance between the pins 8 is greater than 1000MΩ (500V-DC), and the dielectric withstand voltage is greater than 500V.

[0041] The surface of the heat conducting block 9 is required to be flat and smooth. The outer side of the control connector 5 is in the shape of a jack, and the inner side is in the shape of a pin. There are 20-30 control signals in the control connector 5, corresponding to four groups of photoelectric conversion.

[0042] Such as Figure 9 , the pressing plate 7 in the transition cavity can be set as multi-layers, and for more transition cavity components, they are respectively fixed, and after fixing, it is convenient to weld and seal the cover plate. The box body, the pressing plate 7 and the inner surface of the cover plate are provided with 0.5mm deep milling grooves to facilitate the placement or spacing of internal componen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Insulation resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com