An Octane Loss Prediction Method Based on Particle Swarm Optimization Random Forest Parameters

A technology of particle swarm optimization and random forest algorithm, applied in neural learning methods, computer components, instruments, etc., can solve the problems of high complexity of the refining process, untimely response to process optimization, and high requirements for raw material analysis, etc., to achieve reduction Economic cost and time cost, avoiding the effect of overfitting, and solving the effect of comparability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

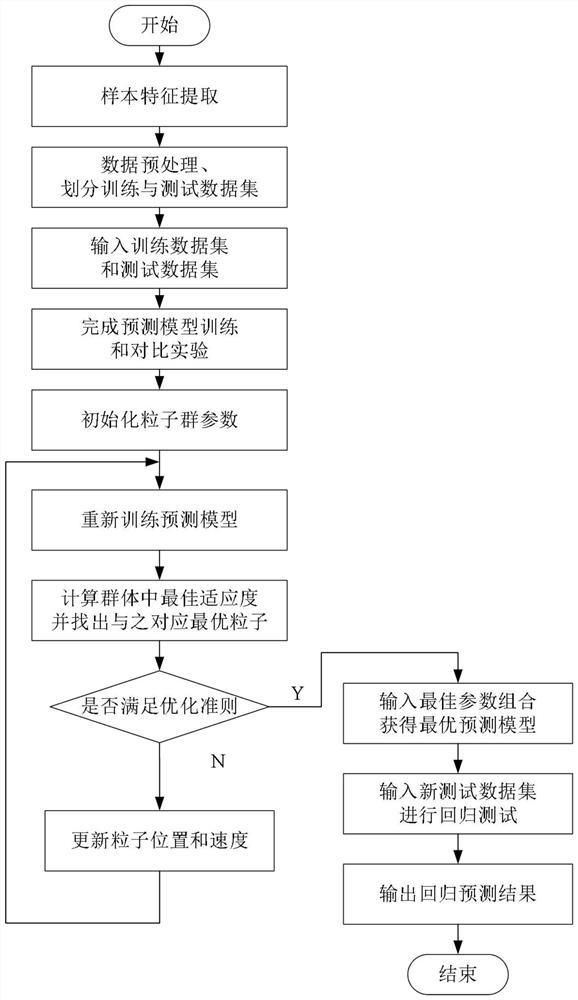

[0028] Example 1: as figure 1 As shown, a method for predicting octane loss value based on particle swarm optimization random forest parameters, the method steps are as follows:

[0029] Step 1. Calculate the information gain value of the relevant features of the octane loss value, and delete the features with less impact on the octane value loss;

[0030] Step 2. Preprocess the remaining data of the features that have less impact on the octane number loss, and divide the preprocessed data into a training data set and a test data set;

[0031] Step 3. Use the training data set to train the random forest algorithm, obtain a training model, and use the test data set to verify the training model;

[0032] Step 4. Initialize the parameters of the particle swarm algorithm;

[0033] Step 5. The root mean square error of the verified random forest algorithm training model is used as the fitness function of the particle swarm algorithm, and the number of parameter decision trees n_e...

Embodiment 2

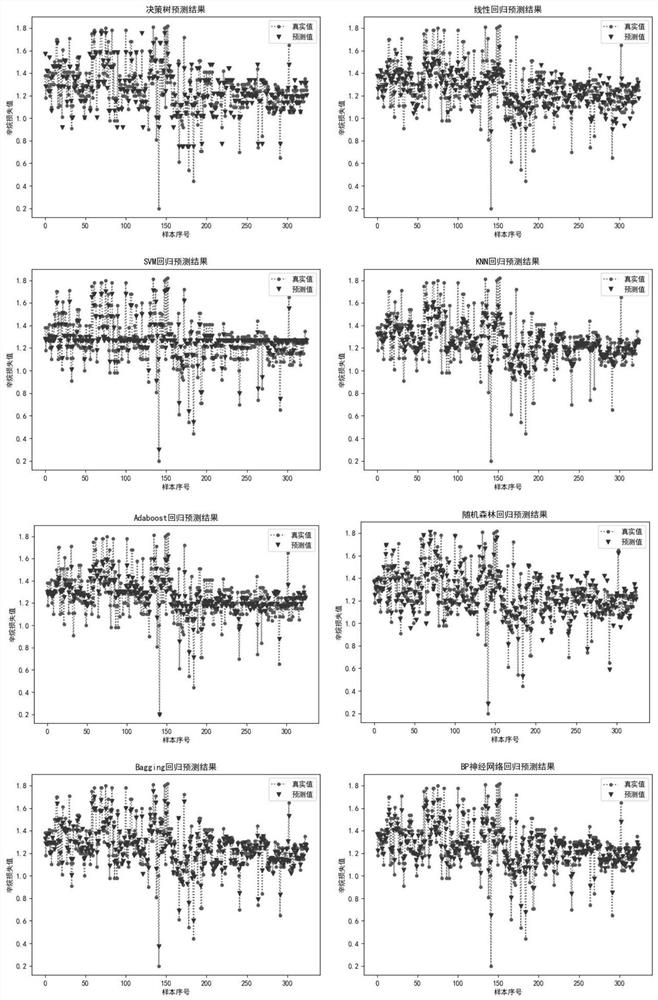

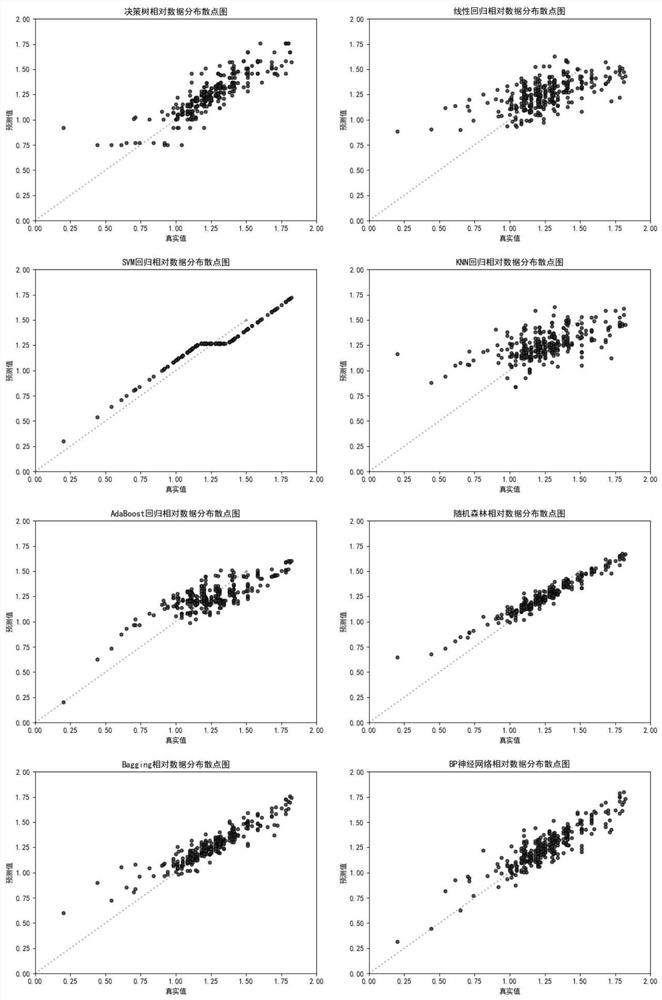

[0052] Embodiment 2: For a prediction method of octane loss value based on particle swarm optimization random forest parameters, the present invention provides the following experimental data process:

[0053] Step 1. Extract the characteristic data that affects the octane loss in the gasoline catalytic cracking process as the original data set, calculate the information gain value of each feature in the original data set, and delete the features with less impact on the octane number loss to avoid excessive generation. fitting problem. Specific steps are as follows:

[0054] 1.1. In the gasoline catalytic cracking process, the reason for the loss of octane is that in the desulfurization process, the hydrodesulfurization leads to the production of excessive olefins and causes the reaction consumption of octane. Therefore, the sensor of the hydrodesulfurization section in the gasoline catalytic cracking process per hour is selected. The collected data is used as the original da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com