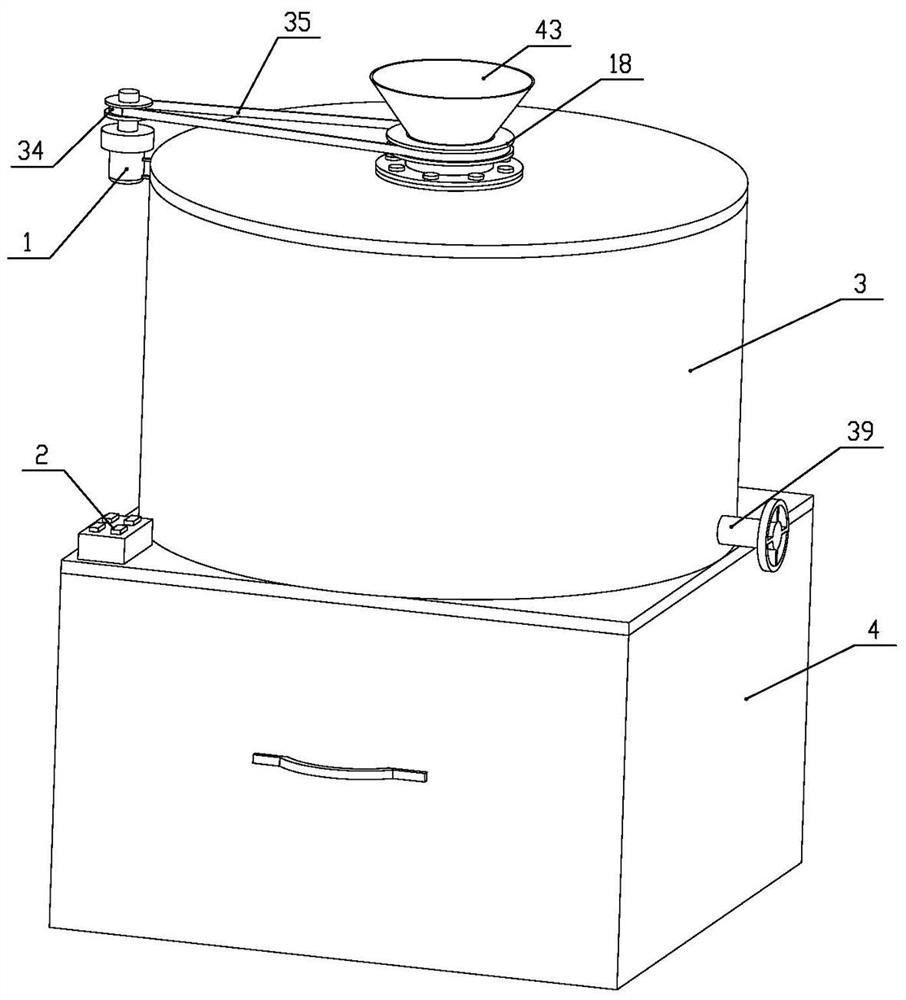

Household flour machine

A technology for household flour mills and speed-regulating motors, which is applied in applications, agricultural machinery and equipment, filter screens, etc., can solve the problems of pollution, low efficiency, and large space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

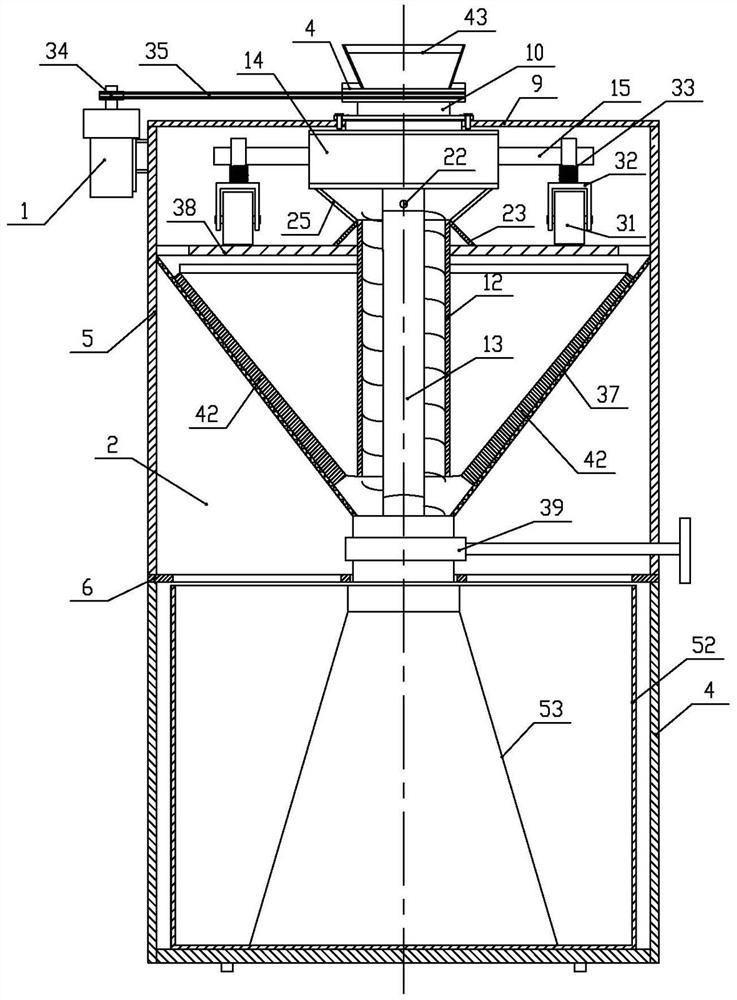

Embodiment 1

[0031] When the present invention is used to prepare flour from wheat and sieve bran, all components mentioned above are prepared and connected and assembled before operation. The total height of the present invention is 1180mm, the power of the speed-regulating motor 1 that is adopted is 200 watts, the rotating speed of the speed-regulating motor 1 is 150 rpm, the outer diameter of the cylindrical box 5 is 350mm, and the height is 400mm. The height is 420mm, and the conical sieve cylinder 37 is a 60-order square hole sieve. Before the grain addition operation of the present invention, the gate valve 39 is closed, and then 5 kilograms of clean wheat are added into the present invention through the feeding cap 43. The gap between the shafts 17 falls on the cloth circular plate 38 through the tapered material guide skirt 23 again. After covering the feeding cap mouth 43, turn on the switch of the speed regulating motor to rotate the speed regulating motor 1 (and ensure the turn...

Embodiment 2

[0034] When the present invention is used to prepare wheat, soybean, mung bean mixed flour (miscellaneous noodles) and screen out the bran, the equipment and operation steps are the same as in Embodiment 1; the gate valve 39 is closed, and then 2 kilograms of clean wheat, 2 After 1 kilogram of soybeans and 1 kilogram of mung beans are added to the present invention through the feeding cap mouth 43 successively, after the feeding cap mouth 43 is covered, the speed regulating motor switch is opened to rotate the speed regulating motor 1, and the governor is adjusted to make the speed regulating motor 1 rotate. The rotating speed (that is, the rotating speed of the lifting screw 13) is matched with the grain being crushed. After a period of time, the grain (wheat, soybean, mung bean) is fully ground and sieved, and passed through the distributing circular plate 38 and the grain scraping plate frame 24 and other components. After the blending of the flour is uniform, the flour fall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com