Double-lateral extension forming device and forming method for irregular curved surface part

A curved part, double lateral technology, applied in the field of sheet metal processing, can solve the problems of increasing the processing cost and production cycle of parts, increasing the risk of unqualified parts, and being unable to form at one time, so as to shorten the production cycle, easy to operate and realize, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074]According to a particular embodiment of the present invention, a bilaterally directed molding method is disclosed, and the forming apparatus of the first embodiment is formed, and the positionally asymmetric projection in both sides is formed. The two feature shape is different, and all are Irregular surface circular bumps. The forming method includes the following steps:

[0075]1) The guide post passes through the through hole on the protruding portion 23 of the upper mold 2, and the second compression spring 7 is arranged outside the guide post 5, and one end of the second compression spring 7 is fixed to the forming surface block 3 in which the internal space is formed. At the bottom of -1, the other end abuts against the bottom surface of the protruding portion 23, the nut 6 is sleeved in the portion of the guide post 5 above the protruding portion, and the press forming assembly 3 is hoisted below the upper mold;

[0076]2) Secure the upper mold 2 to the upper platform of the ...

Embodiment 2

[0086]This embodiment is described in detail to the bilateral direction of the irregular curved sheet sheet metal part.

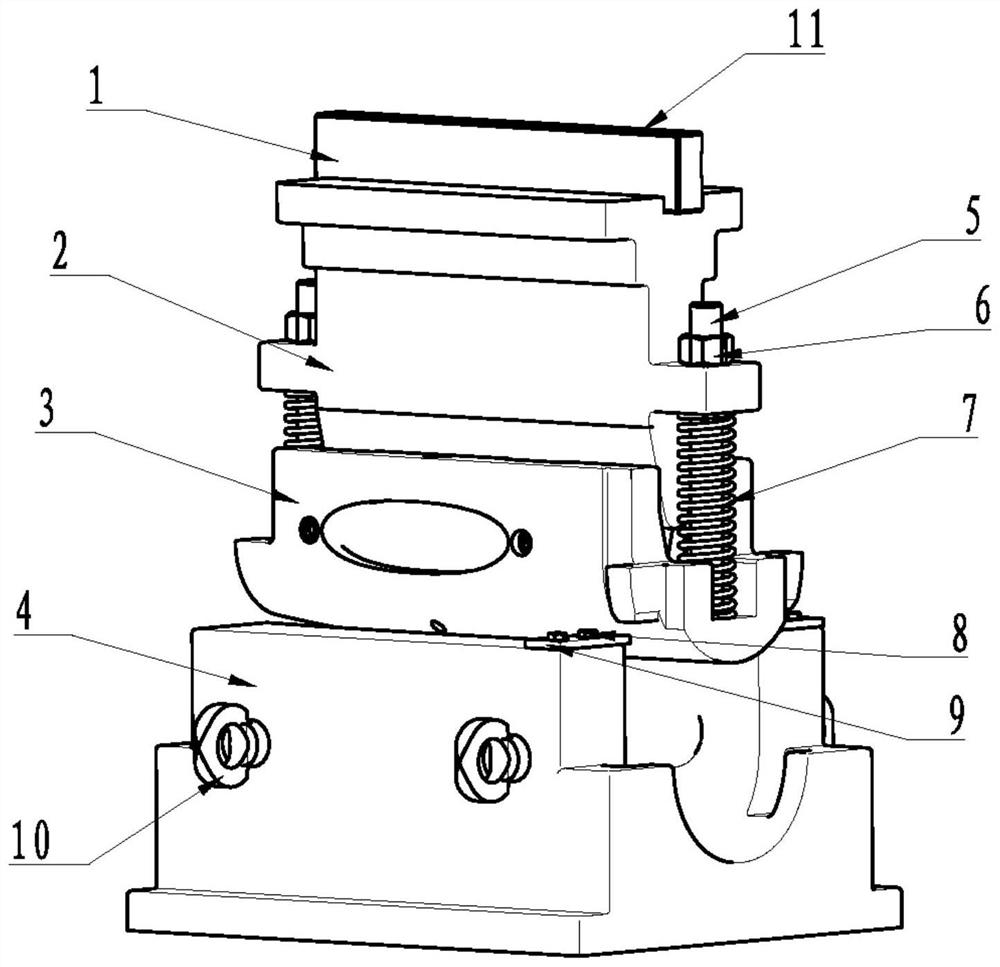

[0087]When the mold is in an open mode,Figure 7-9 As shown, the press forming assembly 3 is hoisted under the upper mold 2 by a guide post 5, the nut 6, and the second compression spring 7 on both sides, and the upper mold 2 is fixed to the upper platform of the hydraulic device by the mold opening 1; The mold 4 is fixed to the lower platform of the hydraulic press.

[0088]At this time, in the press forming assembly 3, the first press clamping mold 3-2 and the second press clamping mold 3-3 are fitted in the through hole of the type surface block 3-1, and the first compression clamp mold 3 The outer surface of the second compressor punch 3-3 cooperates with the through hole surface of the type surface block 3-1, which can be recovered and ejective, such asFigure 9 Indicated.

[0089]The guide screw 3-4 passes through the long round holes on the first compression clamping...

Embodiment 3

[0096]In still another embodiment of the present invention, an extension forming apparatus is disclosed, and the apparatus is used for two lateral extensions of the unregulated curved surface of the above-described embodiment, specifically a irregular surface having a forming feature of the bilateral feature. Sheet metal parts.

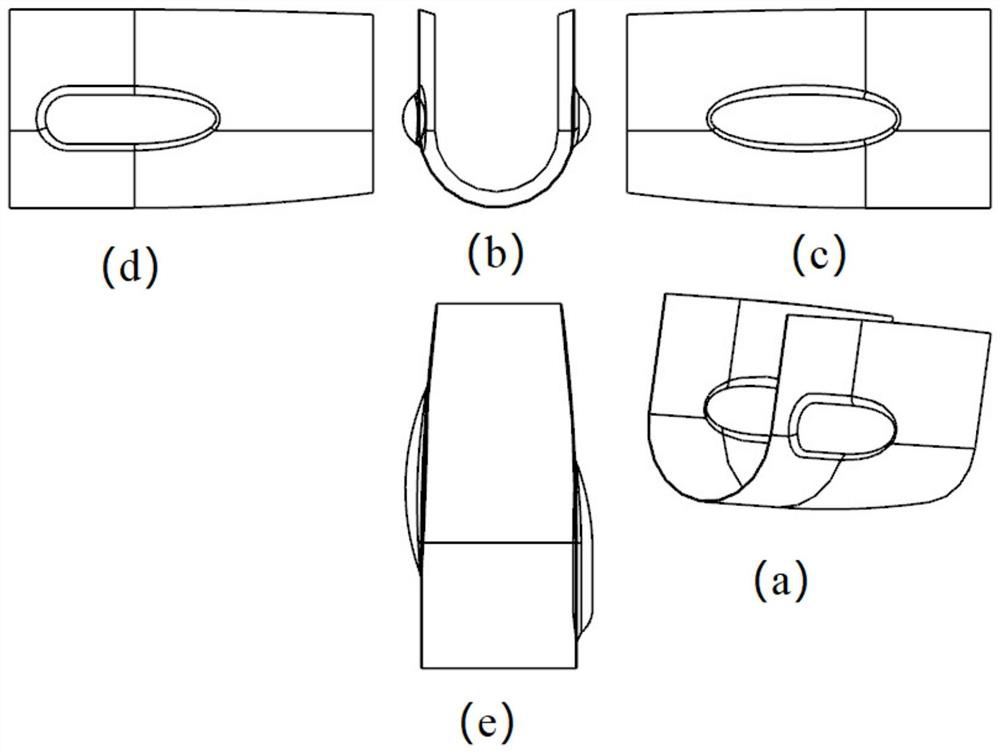

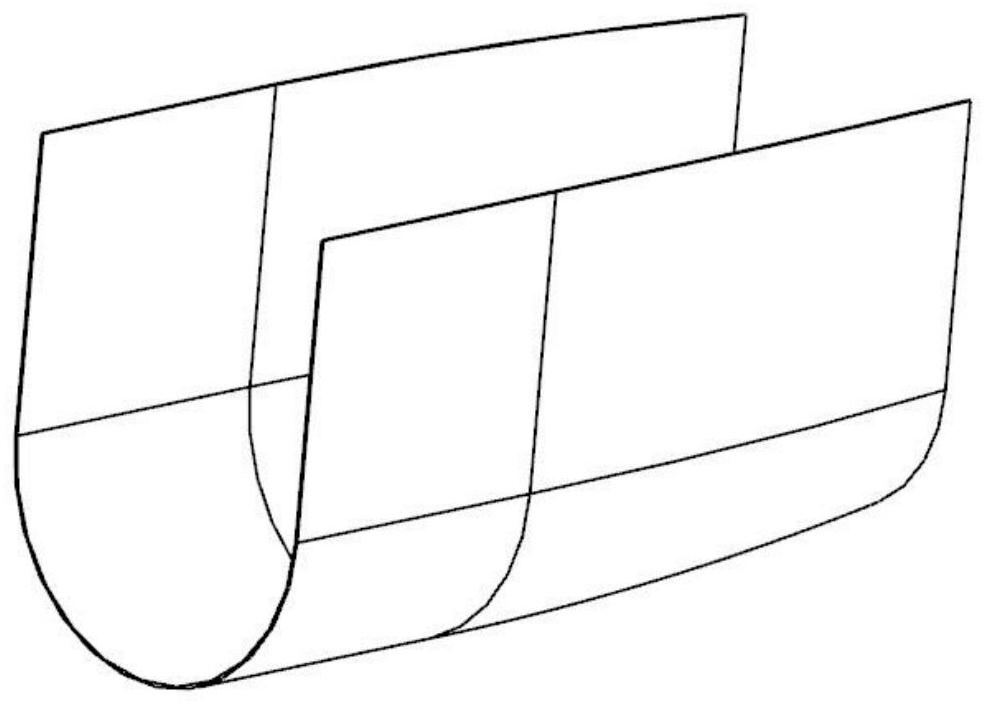

[0097]The material of the sheet metal part is 1 cr18 ni9Ti, a wall thickness of 0.8 mm, and its shape size is likefigure 1 As shown, the part is integrally irregular convergence surface, the head depth is 170mm, the opening width is 130mm, the end depth is 130mm, and the opening is 100 mm. There is a non-symmetrical projection on both sides of the part. The two feature shapes are different, all of which are irregular curved circular projections, and the highest point is 15 mm from the surface.figure 2 For the partial architectural diagram of the parts process, the irregular surface has been completed by the mold extension, and the bilateral features are formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com