High-throughput intelligent sorting method and system for recovering waste plastic

A waste plastics, sorting system technology, applied in plastic recycling, mechanical material recycling, recycling technology and other directions, can solve the problems of low degree of automation, secondary pollution, high energy consumption, etc., to achieve resource reuse and high degree of automation , No secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

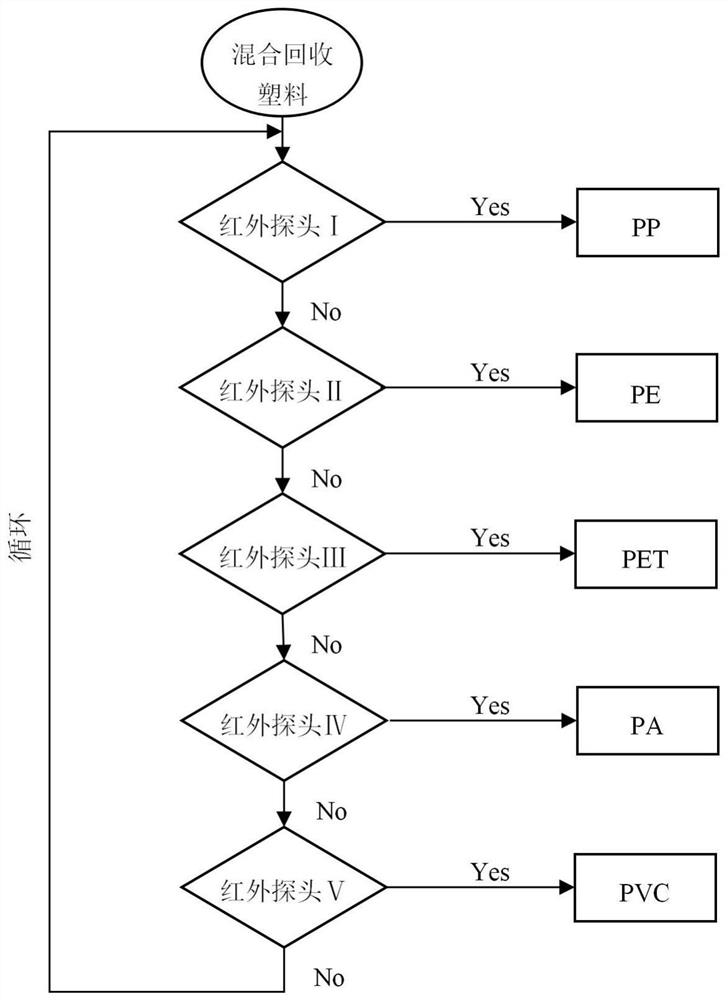

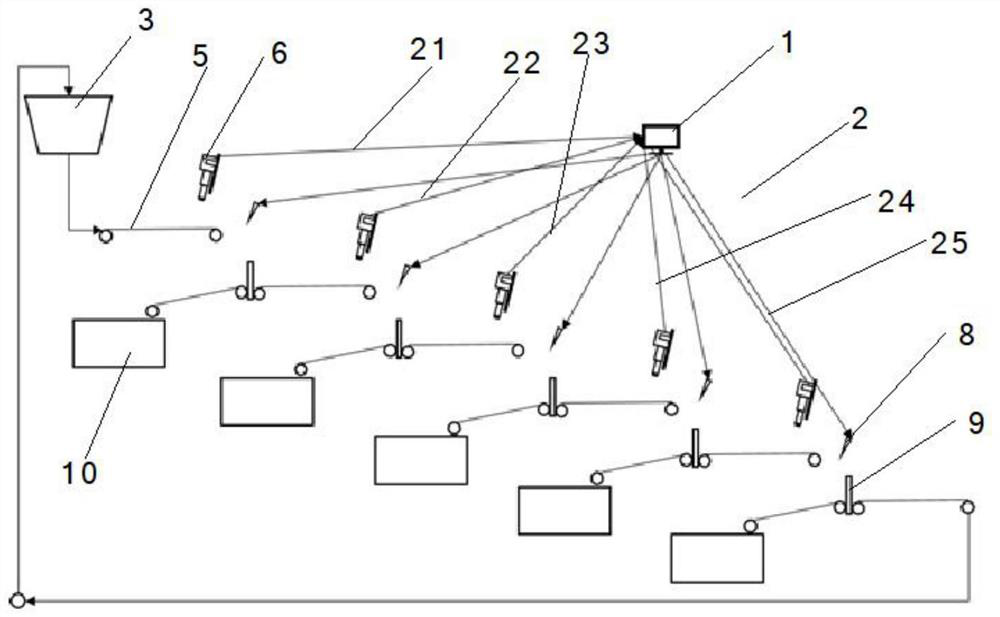

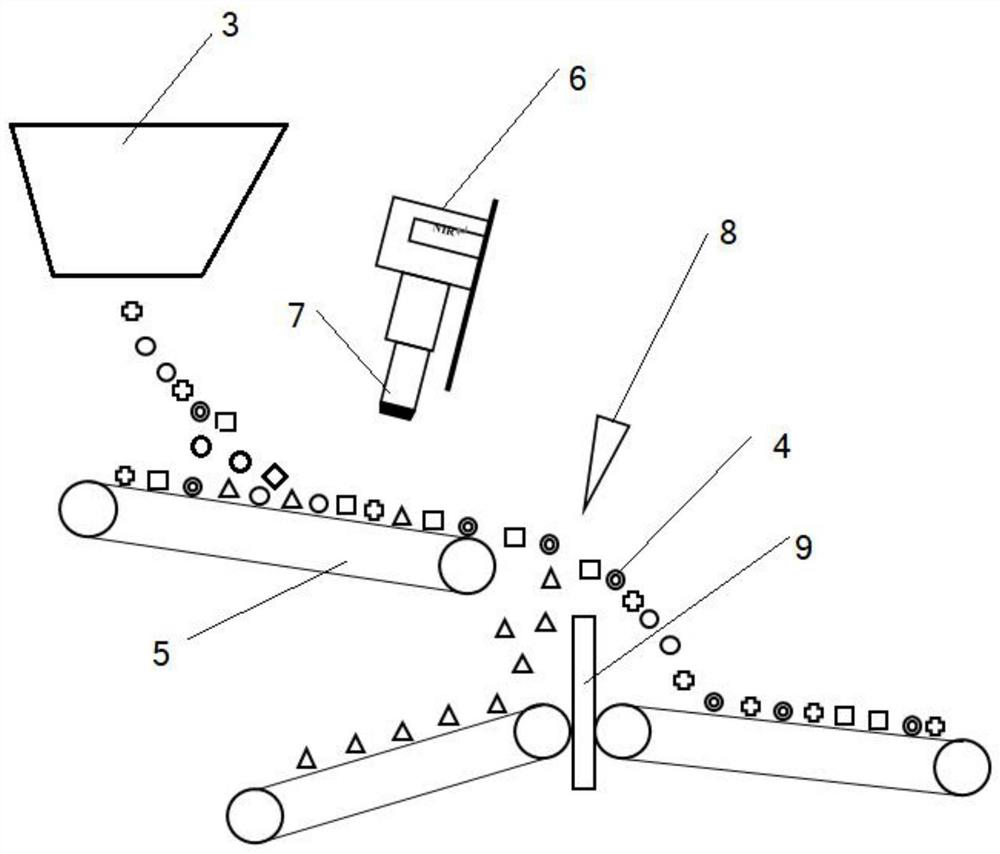

[0041] Please see attached Figure 1~3 , the high-throughput intelligent sorting method for recycling waste plastics provided by the embodiment of the present invention includes the following steps:

[0042] (1) Set up a high-throughput intelligent sorting system, which includes a main controller and a plurality of infrared screening manipulators, and each infrared screening manipulator is equipped with an NIR spectrum recognition system capable of sensing several characteristic peaks specific to different waste plastic components Device and air injection device, each NIR spectrum identification device is equipped with an infrared probe; each screening manipulator is arranged in layers from top to bottom from the hopper to form a multi-layer infrared screening production line;

[0043] (2) Put the recovered mixed waste plastic fragments into the hopper, and then transfer them to the infrared screening manipulators sequentially by the conveyor belt, and slide down one by one. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com