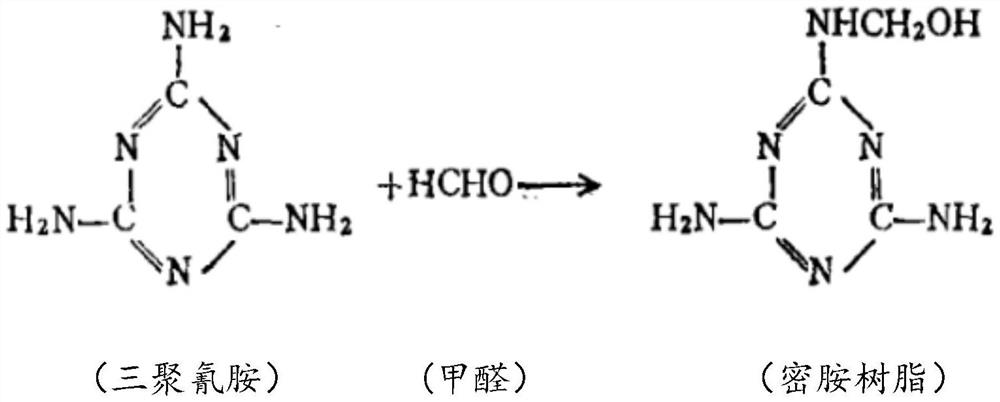

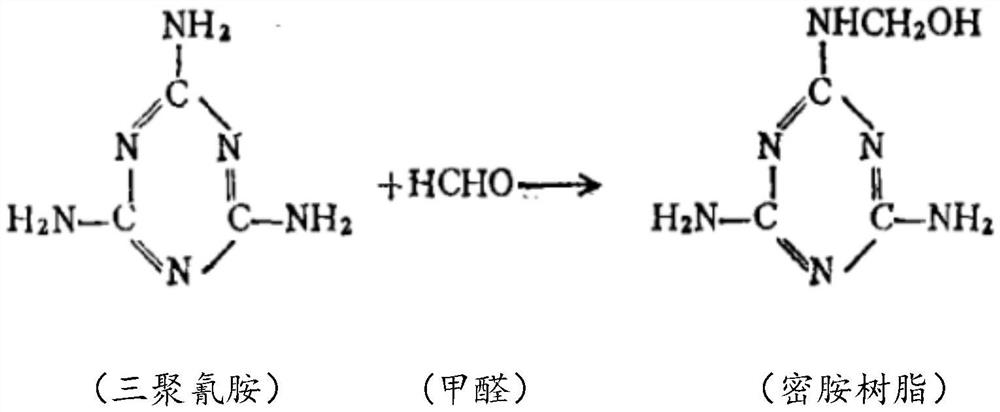

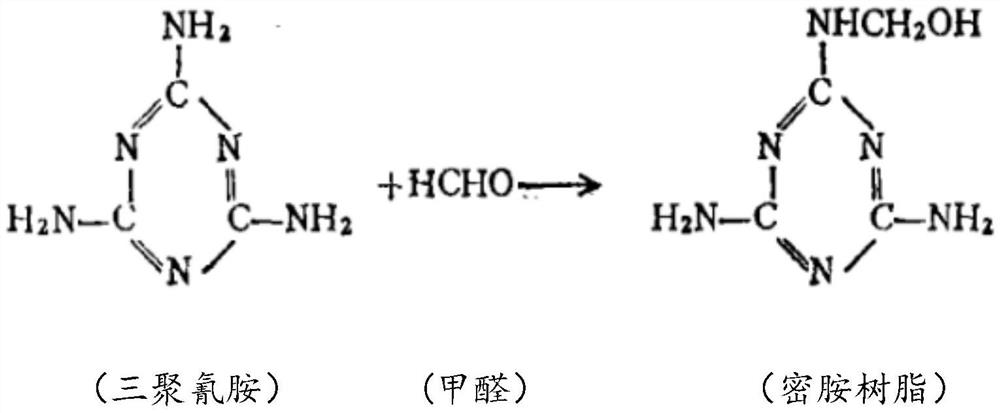

Printing method of melamine resin product and melamine container

A technology of melamine resin and printing method, which is applied in the direction of crafts, decorative arts, and household components for producing decorative surface effects, and can solve the problems of dullness, poor printing effect, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention, but this does not constitute a limitation to the protection scope of the present invention.

[0028] The present embodiment provides a kind of printing method of melamine resin product, comprises the following steps:

[0029] (1) Baking, first hang a stack of 50 long-fiber decals in an oven with a temperature of 80-85°C to bake, so as to dry the ink on the decals, the temperature is preferably 82°C;

[0030] (2) To prepare melamine formaldehyde resin slurry water, first add industrial pure water with a temperature of 90-95°C and a mass of 700 grams into the mixer. The water quality of industrial pure water requires a resistivity greater than or equal to 5MΩ*cm, and then add in order 218 grams of 907-2501#LG model bright powder, 20 grams of 907-2202#LG model bright powder, 20 grams of 907-220#LG model bright powder, and 10 grams produced by Songyi Indus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com