High-modulus insulating flame-retardant pp double-wall corrugated pipe and preparation method thereof

A double-wall corrugated pipe and corrugated pipe technology, applied in the field of corrugated pipes, can solve problems such as inconvenient removal of burrs, large cooling water consumption, and injury to staff, and achieve the effects of fast and convenient cooling, avoiding injuries, and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

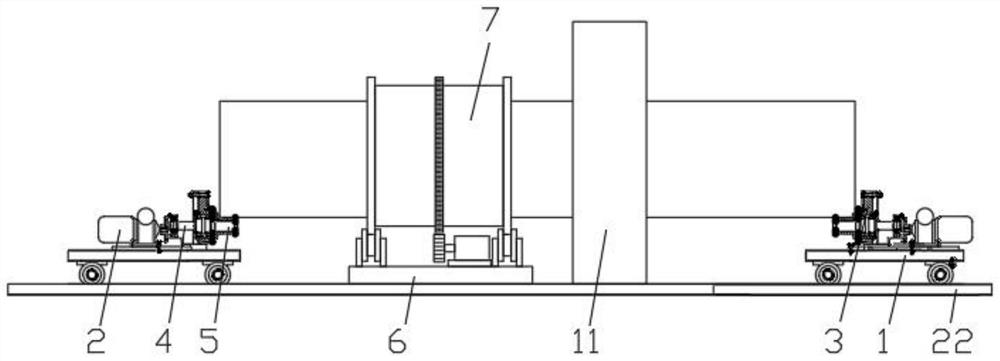

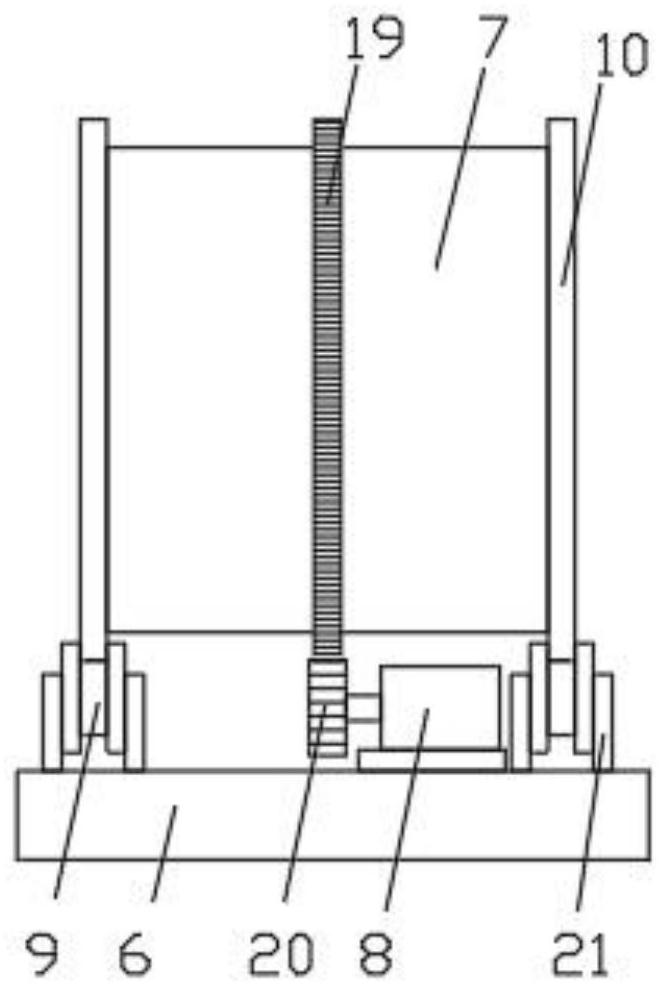

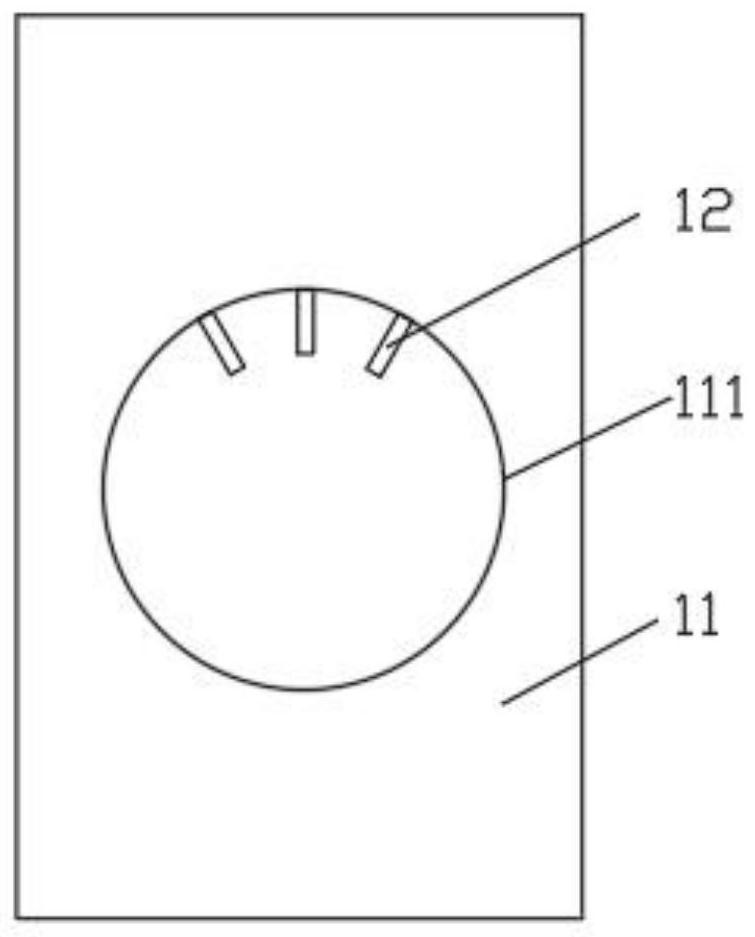

[0040] Such as Figure 1-4 As shown, a high-modulus insulating flame-retardant pp double-wall corrugated pipe is prepared from the following raw materials in parts by mass:

[0041] 42 parts of matrix material, 2 parts of ethylene octene copolymer or olefin block copolymer, 2 parts of high modulus impact-resistant filler masterbatch, 0.7 part of heat-resistant, insulating and flame-retardant functional masterbatch.

[0042] The high-modulus impact-resistant filling masterbatch is made of polypropylene, PET, ultra-high molecular polyethylene, nano-modified talcum powder, and glass fiber microbeads according to the mass ratio of 4:2.5:3:0.1:0.3 and then extruded Granulation obtained.

[0043] A method for preparing a high-modulus insulating flame-retardant pp double-wall corrugated pipe, the method specifically comprising the following steps:

[0044] Step 1. Mix the matrix material, one or any mixture of ethylene octene copolymer and olefin block copolymer, high modulus impac...

Embodiment 2

[0057] Such as Figure 1-4 As shown, a high-modulus insulating flame-retardant pp double-wall corrugated pipe is prepared from the following raw materials in parts by mass:

[0058] 48 parts of matrix material, 5 parts of ethylene octene copolymer or olefin block copolymer, 10 parts of high modulus impact-resistant filler masterbatch, 0.9 part of heat-resistant, insulating and flame-retardant functional masterbatch.

[0059] The high-modulus impact-resistant filling masterbatch is made of polypropylene, PET, ultra-high molecular polyethylene, nano-modified talcum powder, and glass fiber microbeads according to the mass ratio of 4:2.5:3:0.1:0.3 and then extruded Granulation obtained.

[0060] A method for preparing a high-modulus insulating flame-retardant pp double-wall corrugated pipe, the method specifically comprising the following steps:

[0061] Step 1. Mix the matrix material, one or any mixture of ethylene octene copolymer and olefin block copolymer, high modulus impa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt finger | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com