Single-component graphene zinc powder coating and preparation method thereof

A graphene, one-component technology, used in anti-corrosion coatings, epoxy coatings, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

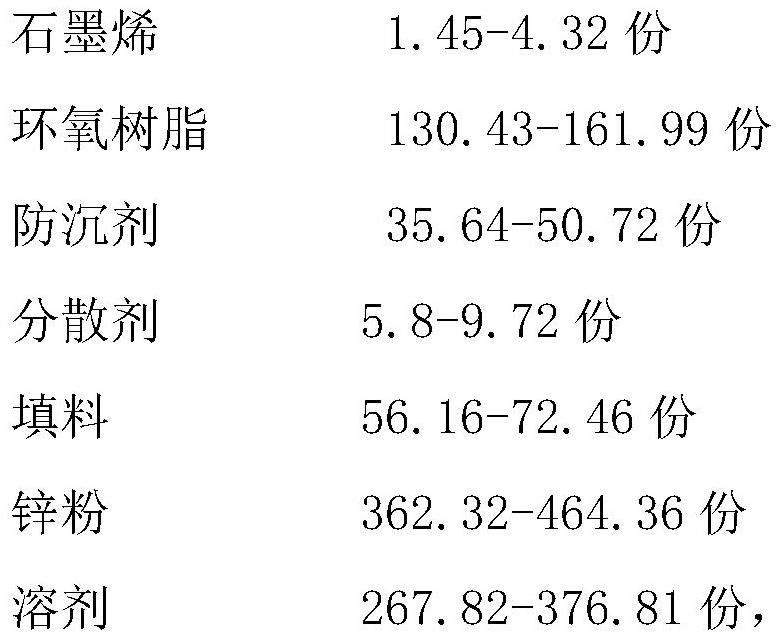

[0034] A kind of one-component graphene zinc powder coating of the present invention is mainly prepared according to the following parts by weight ratio by following components:

[0035]

[0036] Wherein, the solvent is formulated according to the mass ratio of 6:3:1 by xylene, n-butanol and methyl isobutyl ketone or cyclohexanone;

[0037] The graphene is redox graphene or mechanically exfoliated graphene, and the number of layers is ≤10 layers;

[0038] The epoxy resin is a bisphenol A type epoxy resin with a molecular weight of 2500-5500.

[0039] The preparation method of described one-component graphene zinc powder coating mainly comprises the following steps carried out in sequence:

[0040] (1) Start the mixer, and adjust the stirring speed to 200r / min, add the solvent that accounts for 90% of its own weight percentage in the mixer, then add epoxy resin and dispersant in turn, stir until mixed evenly,

[0041] (2) keep the stirring speed of 200r / min, add graphene a...

Embodiment 2

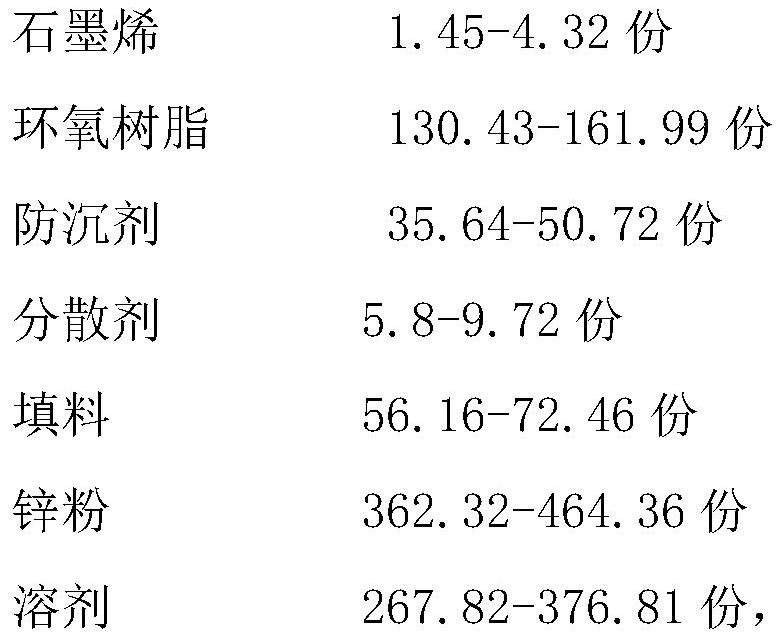

[0045] A kind of one-component graphene zinc powder coating of the present invention is mainly prepared according to the following parts by weight ratio by following components:

[0046]

[0047]

[0048] Wherein, the solvent is formulated according to the mass ratio of 5:3:1 by xylene, n-butanol and methyl isobutyl ketone or cyclohexanone;

[0049] The graphene is redox graphene or mechanically exfoliated graphene, and the number of layers is 4-6 layers;

[0050] The epoxy resin is a bisphenol A type epoxy resin with a molecular weight of 3000-5000.

[0051] The preparation method of described one-component graphene zinc powder coating mainly comprises the following steps carried out in sequence:

[0052] (1) Start the mixer, and adjust the stirring speed to 300r / min, add the solvent accounting for 93.03% of its own weight percentage in the mixer, then add epoxy resin and dispersant in turn, stir until mixed evenly,

[0053] (2) keep the stirring speed of 300r / min, ad...

Embodiment 3

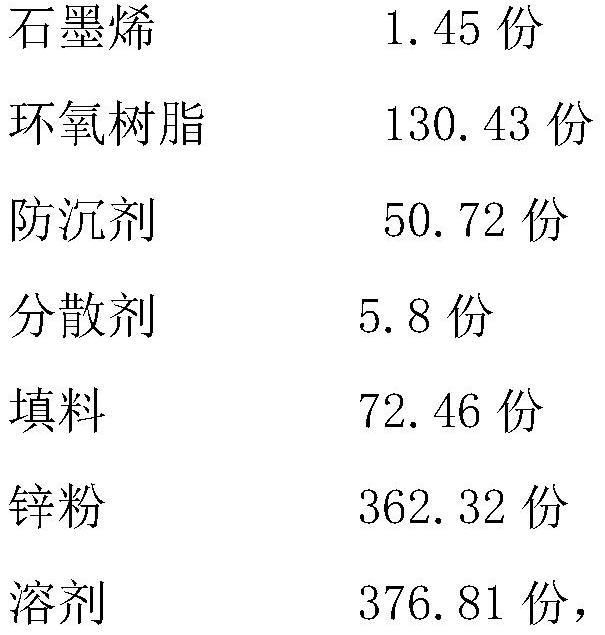

[0057] A kind of one-component graphene zinc powder coating of the present invention is mainly prepared according to the following parts by weight ratio by following components:

[0058]

[0059] Wherein, the solvent is prepared from xylene, n-butanol and methyl isobutyl ketone or cyclohexanone according to the mass ratio of 7:3:1;

[0060] The graphene is redox graphene or mechanically exfoliated graphene, with 4-6 layers.

[0061] The epoxy resin is a bisphenol A type epoxy resin with a molecular weight of 3000-5000.

[0062] The preparation method of described one-component graphene zinc powder coating mainly comprises the following steps carried out in sequence:

[0063] (1) Start the stirrer, and adjust the stirring speed to 250r / min, add the solvent accounting for 92% of its own weight percentage in the stirrer, then add epoxy resin and dispersant in turn, stir until mixed evenly,

[0064] (2) keep the stirring speed of 250r / min, add graphene and anti-sedimentation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com