Mask manufacturing device and manufacturing method

A technology for manufacturing devices and masks, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of stagnant manufacturing accuracy and difficulty in further improving the manufacturing accuracy of metal masks, so as to improve the fixed accuracy, improve the manufacturing accuracy, Effect of improving positional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

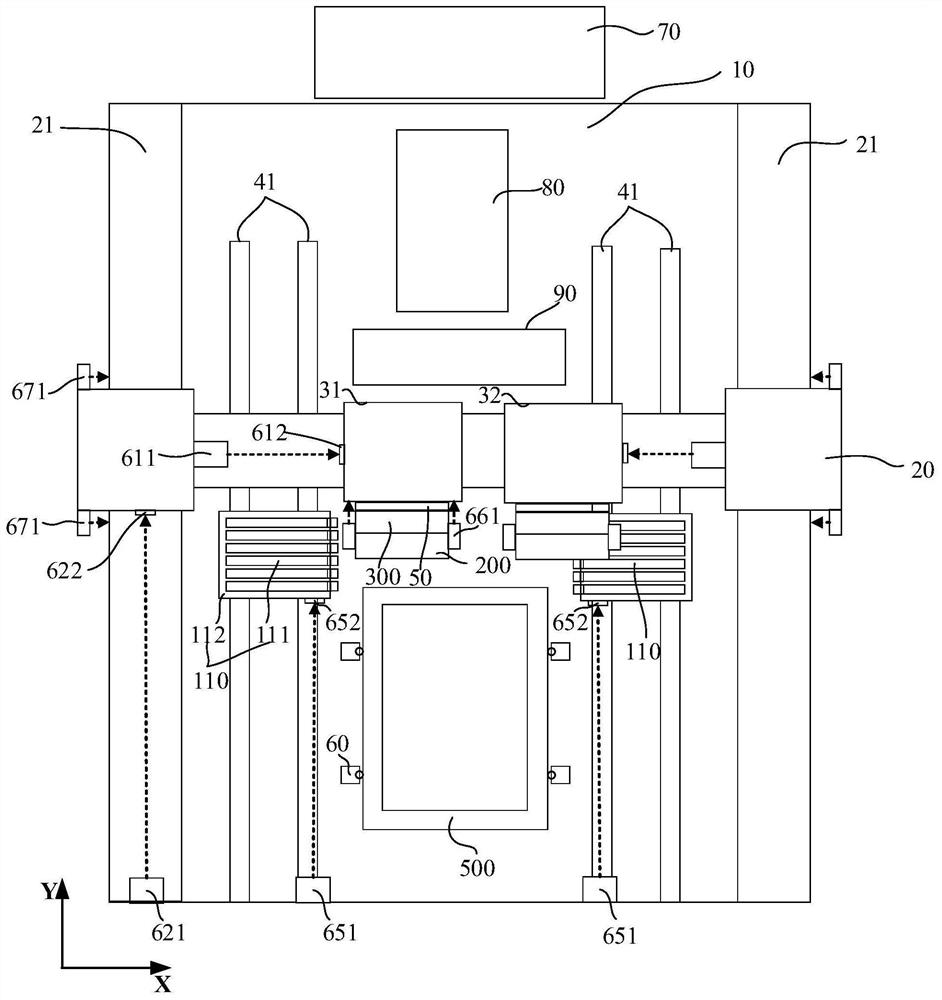

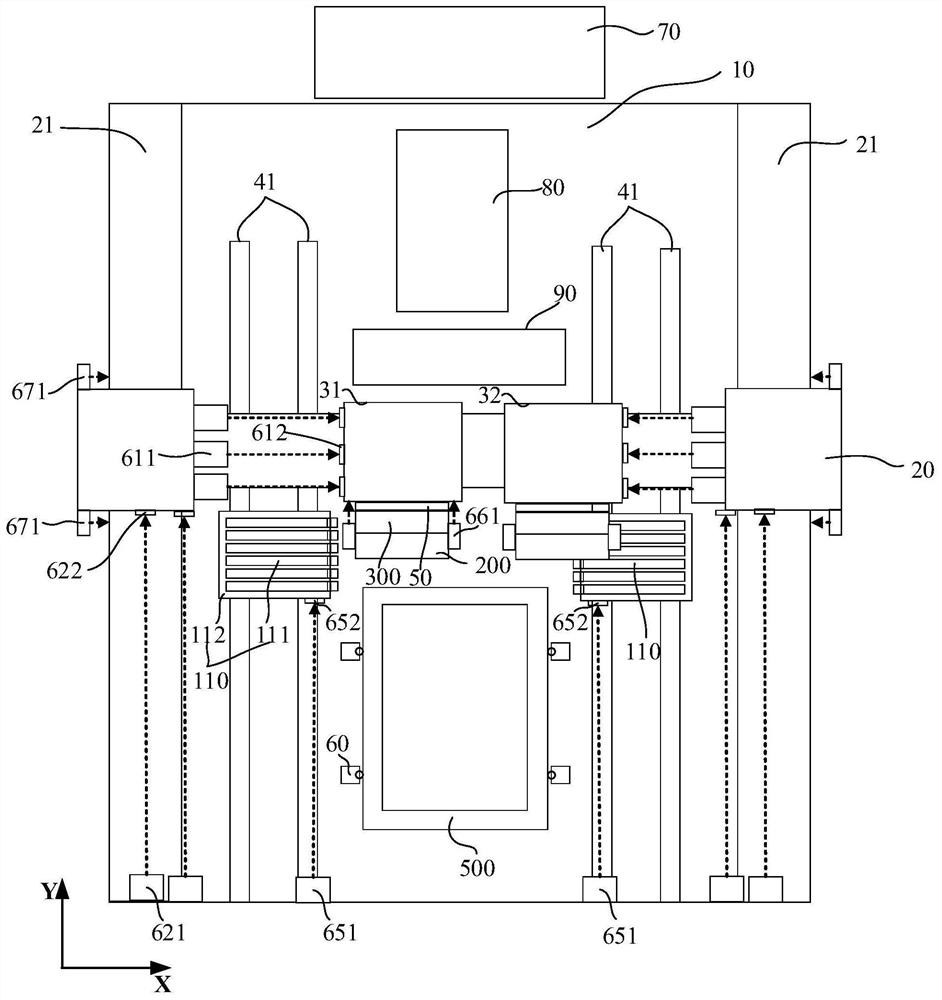

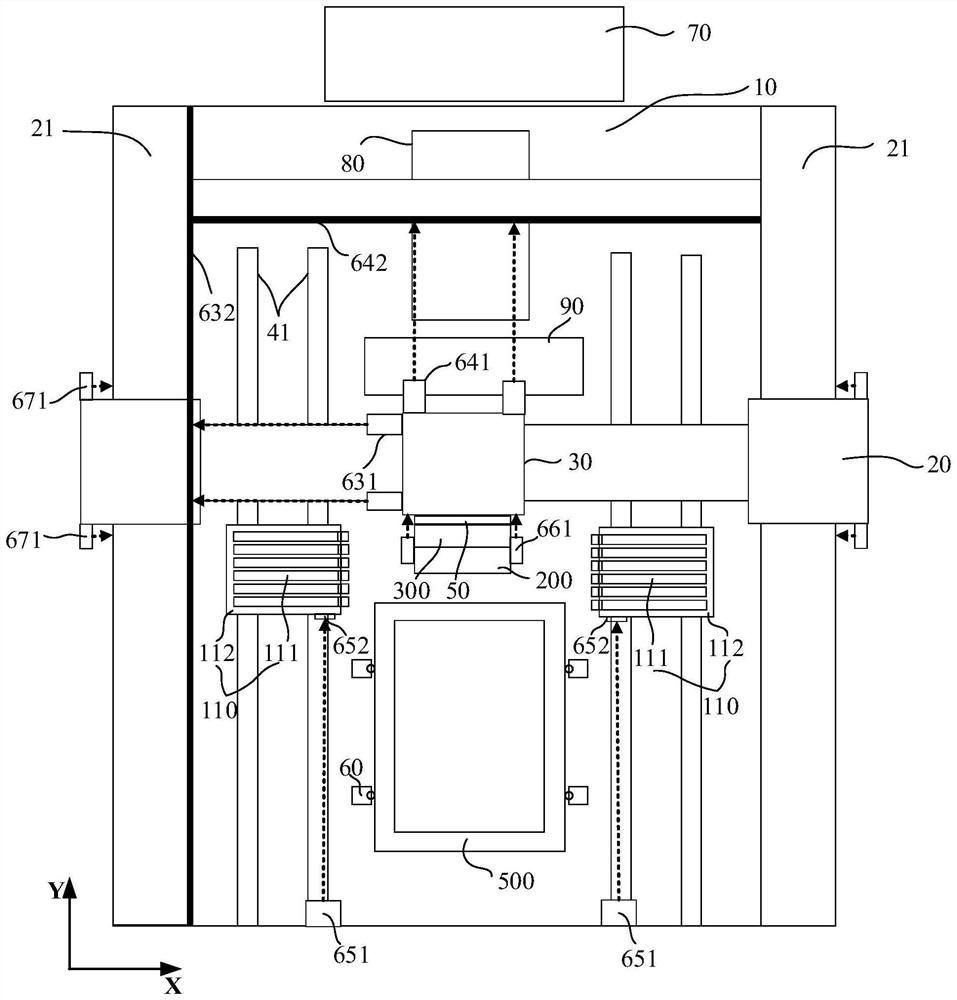

[0111] An embodiment of the present invention provides a mask manufacturing method, which is based on the mask manufacturing device provided in the above embodiments of the present invention, Figure 5 A flow chart of a mask manufacturing method provided by an embodiment of the present invention, such as Figure 5 As shown, the mask making method includes:

[0112] S101. Establish a reference coordinate system.

[0113] Exemplarily, firstly, a reference plane is selected, which is perpendicular to the Z direction. The reference plane may be the plane where the surface of the base is located, the plane where the surface of the moving table is located, the plane where the surface of the gantry beam is located, etc. The embodiment of the present invention is here There is no limitation, as long as the reference plane is perpendicular to the Z direction. Then, a reference coordinate system is established in the reference plane. For example, the geometric center of the mask frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com