A kind of polymer waterproof membrane and its forming method

A technology of polymer waterproofing and waterproofing membranes, which can be applied to other household appliances, building insulation materials, and roofs using flexible materials, etc. It can solve problems such as waste of raw materials, lack of pre-washing process, oil thickness and unsatisfactory finished product effects, etc. , to achieve the effect of improving the effect of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

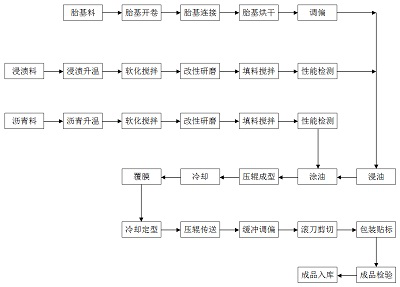

[0048] The present invention will now be described in further detail with reference to the accompanying drawings. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0049] A polymer waterproofing membrane (ie, GPS-SL reactive bonding wet-laying polymer waterproofing membrane), the waterproofing membrane comprises the following components in parts by mass: 0.50-0.55% of petroleum asphalt, 0.05% of high-activity rubber powder -0.10%, aromatic oil 0.10-0.15%, styrene SBS 0.10-0.15%, styrene butadiene rubber SBR 0.05-0.10%, and stone powder 0.05-0.10%.

[0050] like figure 1 As shown, the present invention also provides a method for forming a polymer waterproof coiled material, comprising the following steps:

[0051] 1) Preparation of asphalt material:

[0052] 1.1) Detect whether the raw material formulation of asphalt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com