Synthesis method of chemical reagent auxiliary agent containing acetate

A technology of chemical reagents and synthesis methods, applied in chemical instruments and methods, separation/purification of carboxylic acid esters, organic chemistry, etc., can solve problems such as excessive internal moisture, more impurities, and purity that cannot meet certain requirements, and achieve Improve the effect of finished products, improve the purity of the solution, and improve the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

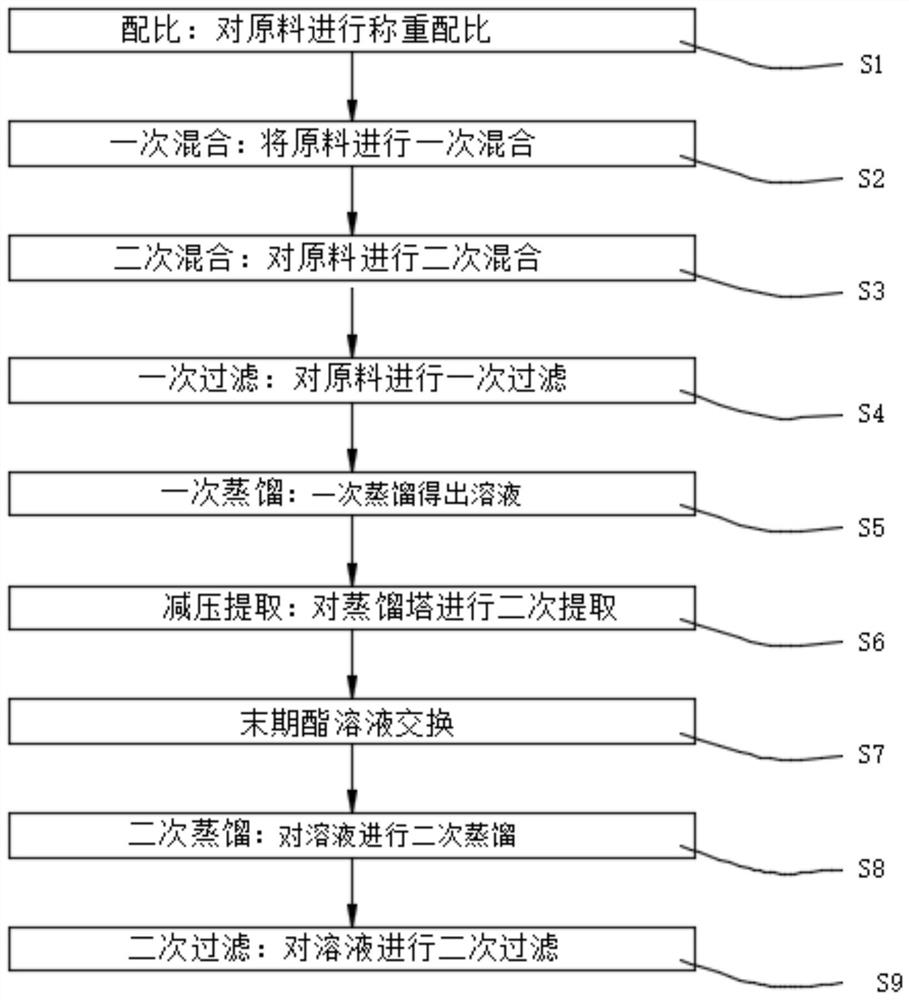

[0034] see figure 1 , the present invention provides a kind of technical scheme: a kind of synthetic method of chemical reagent auxiliary agent containing acetate, comprises the following steps:

[0035] S1, proportioning: 10 parts by weight of catalyst, 5 parts by weight of acetic acid, 1 part by weight of water and 10 parts by weight of methyl acetate are weighed and proportioned;

[0036] S2, primary mixing: pump 5 parts by weight of acetic acid, 10 parts by weight of water and 10 parts by weight of methyl acetate into a gravity-free heating mixer for preheating and mixing;

[0037] S3, secondary mixing: stop mixing after 3 minutes and add 10 parts by weight of catalyst, add 1 part by weight of water and 8 parts by weight of catalyst again, and start the gravity-free heating mixer again;

[0038] S4, primary filtration: filter and desalt the raw materials after heating and mixing;

[0039] S5, primary distillation: pump the raw material into the distillation tower, pressu...

Embodiment 2

[0055] see figure 1 , the present invention also provides a kind of technical scheme: a kind of synthetic method of the chemical reagent auxiliary agent containing acetate, comprises the following steps:

[0056] S1, proportioning: 12 parts by weight of catalyst, 6 parts by weight of acetic acid, 11 parts by weight of water and 1.3 parts by weight of methyl acetate are weighed and proportioned;

[0057] S2, primary mixing: pump 5 parts by weight of acetic acid, 10 parts by weight of water and 10 parts by weight of methyl acetate into a gravity-free heating mixer for preheating and mixing;

[0058] S3, secondary mixing: stop mixing after 3 minutes and add 12 parts by weight of catalyst, add 1.3 parts by weight of water and 9 parts by weight of catalyst again, and start the gravity-free heating mixer again;

[0059] S4, primary filtration: filter and desalt the raw materials after heating and mixing;

[0060] S5, primary distillation: pump the raw material into the distillation ...

Embodiment 3

[0076] see figure 1 , the present invention also provides a kind of technical scheme: a kind of synthetic method of the chemical reagent auxiliary agent containing acetate, comprises the following steps:

[0077] S1, proportioning: 15 parts by weight of catalyst, 10 parts by weight of acetic acid, 3 parts by weight of water and 15 parts by weight of methyl acetate are weighed and proportioned;

[0078] S2, primary mixing: 10 parts by weight of acetic acid, 113 parts by weight of water and 15 parts by weight of methyl acetate are pumped into a gravity-free heating mixer for preheating and mixing;

[0079] S3, secondary mixing: stop mixing after 5 minutes and add 15 parts by weight of catalyst, add 1.5 parts by weight of water and 10 parts by weight of catalyst again, and start the gravity-free heating mixer again;

[0080] S4, primary filtration: filter and desalt the raw materials after heating and mixing;

[0081] S5, primary distillation: pump the raw material into the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com