Method for preparing emulsion by simulating stratum shearing through reciprocating shearing, simulated emulsion and application of simulated emulsion

A technique for simulating formations and emulsions, used in the preparation of samples for testing, testing material strength using a stable shear force, analysis of suspensions and porous materials, etc. , it is difficult to achieve viscosity reduction and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

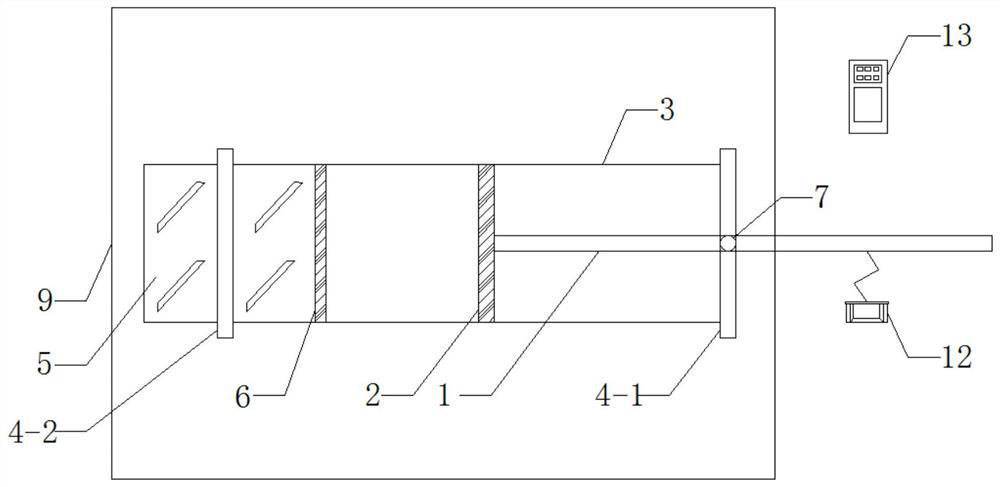

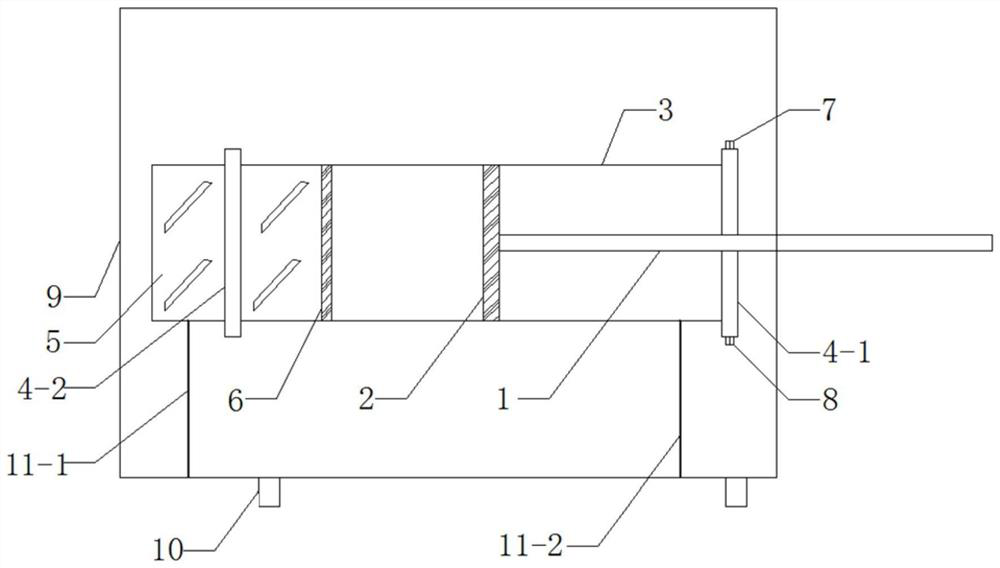

[0046] This embodiment provides a device for simulating formation tunnels with a porous plate, figure 1 with figure 2 are the top view and side view of the device, respectively. The device specifically includes: a constant temperature box 9 , a mixing pipe 3 , a driving motor 12 , a transmission rod 1 and a perforated plate 2 .

[0047] The incubator 9 is provided with a cavity inside and a base 10 outside. The mixing pipe 3 , the transmission rod 1 and the perforated plate 2 are all located inside the incubator 9 . The mixing pipe 3 is fixed at the bottom of the inner chamber of the incubator through the first bracket 11-1 and the second bracket 11-2. Drive motor 12 is located at the outside of thermostatic box, easy to operate.

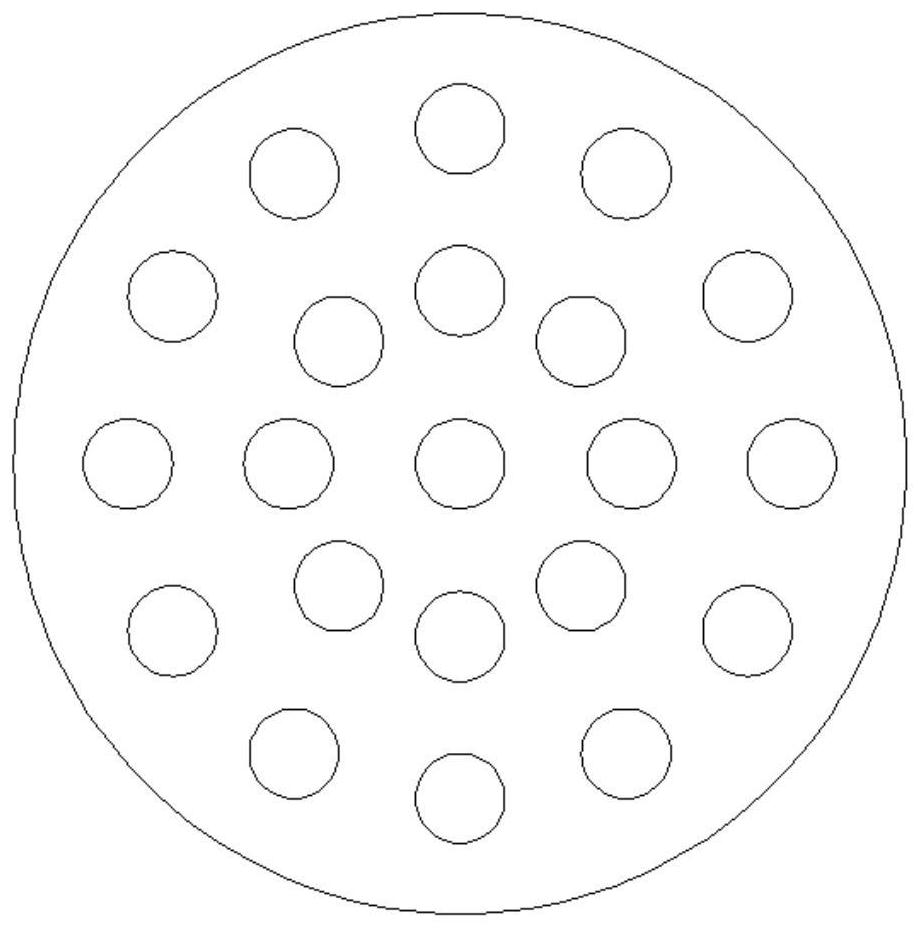

[0048] The material mixing pipe 3 is a pipe body with openings at both ends, a first baffle plate 4-1 is provided on one end opening, and a second baffle plate 4-2 is provided on the other end opening. One end of the first baffle 4-1 is provid...

Embodiment 2

[0053] This embodiment provides a method for preparing an emulsion by reciprocating shear simulation formation shear, which is carried out in the device of Example 1, and specifically includes the following process:

[0054] Select a mixing tube with a volume of 200ml, add 24g of oil well emulsion dehydration and crude oil 96g of oil well emulsion to separate water, the mass ratio of oil well emulsion dehydrated crude oil and oil well emulsion to separate water is 2:8, close the first valve of the liquid inlet, Start the driving motor to make the transmission rod and the perforated plate do a reciprocating shearing motion. After 4 hours, a simulated emulsion is formed in the mixing tube. When it is necessary to test the simulated emulsion, the driving motor is turned off, the second valve of the liquid outlet is opened, and the simulated emulsion is taken out.

[0055] Among them, the shear frequency of the perforated plate is determined according to the following process:

...

Embodiment 3

[0067] This embodiment provides a method for preparing an emulsion by simulating formation shearing. In this method, 72 g of a viscosity reducer aqueous solution with a mass concentration of 0.1% is used to replace 96 g of the oil well emulsion water in Example 2, and the dehydrated crude oil of the oil well emulsion is 48 g. The operation and parameters were the same as in Example 2 to obtain a simulated emulsion containing a viscosity reducer.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap