Waterproof and breathable underground cable capable of preventing mistaken digging and breaking

An underground cable, breathable technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problem of electrical components being out of power and cannot be used, and achieve the effect of increasing service life, increasing strength, and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

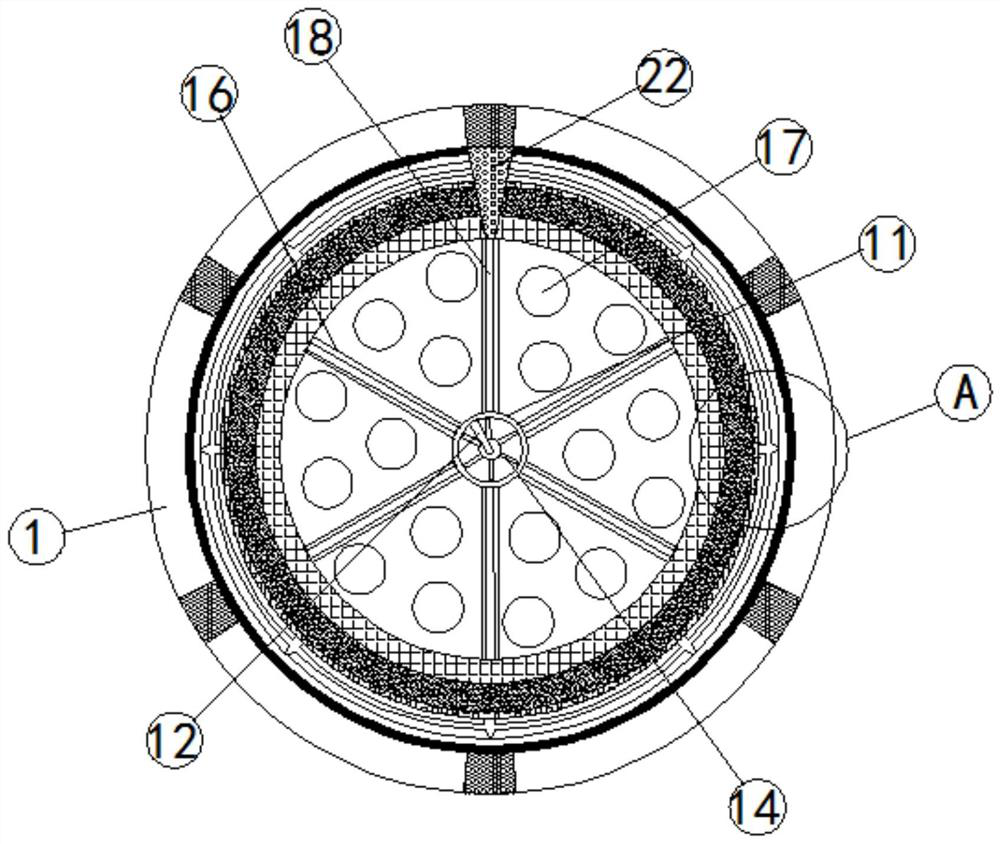

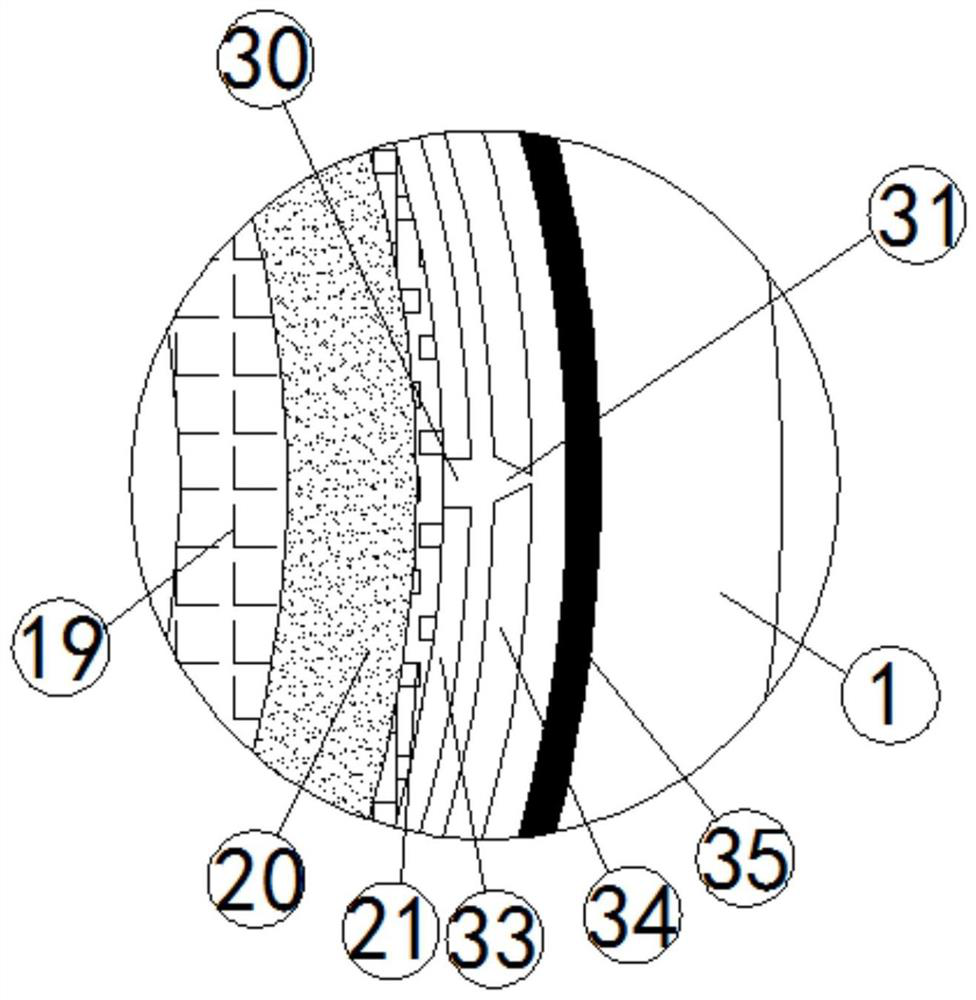

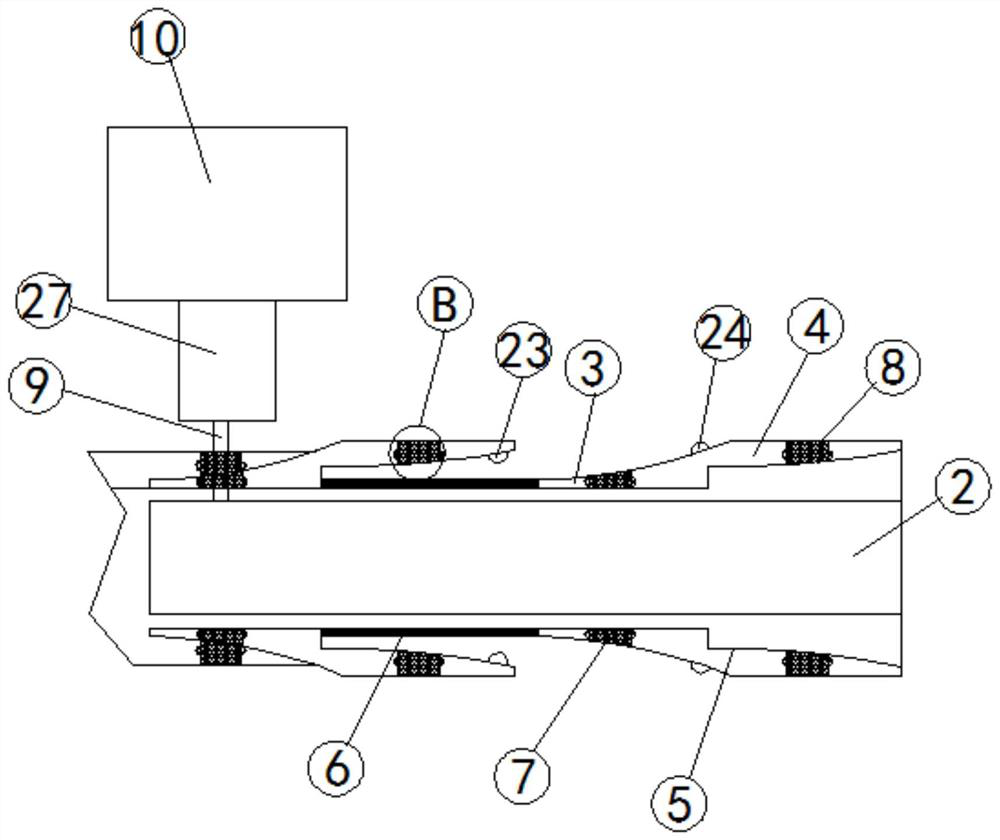

[0034] see Figure 1-6 , according to an embodiment of the present invention, a waterproof and breathable underground cable to prevent accidental digging, comprising an outer tube 1 and an inner tube 2, the outer tube 1 is sleeved outside the inner tube 2, and the outer tube 1 includes The connection end 3 and the contact end 4, the contact end 4 is provided with a card slot 5, the connection end 3 is connected to the inner wall of the card slot 5 through a rubber tube 6, and the connection end 3 is connected to the The card slot 5 is matched, and the connecting end 3 and the contacting end 4 are respectively embedded with a first rubber plug 7 and a second rubber plug 8, wherein a set of the first rubber plug 7 and the second rubber plug 8 are A puncture needle 9 is provided throughout, and the puncture needle 9 is connected to the output end of the fan 10. The inner pipe 2 includes a first air duct 11, and a plurality of L-shaped connecting rods 12 are fixed inside the first...

Embodiment 2

[0037] see again Figure 1-6 , for the card slot 5, the inner wall of the card slot 5 is provided with a first rubber ring 23, and the outside of the connecting end 3 is provided with a second rubber ring 24, and the first rubber ring 23 and the second rubber ring 24 matches. Through the first rubber ring 23 and the second rubber ring 24, the connection stability between the connecting end 3 and the draw-in groove 5 can be effectively guaranteed. For the puncture needle 9, the puncture needle 9 includes a needle point 25 and a connecting sleeve 26, and the needle point 25 passes through the first rubber stopper 7, the second rubber stopper 8 and the third rubber stopper 22 in sequence, and the needle point One end of 25 is fixed with the connecting sleeve 26 , and one end of the connecting sleeve 26 communicates with the output end of the fan 10 through the second air pipe 27 . By setting the puncture needle 9, it can be ensured that the airflow driven by the fan 10 can smoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com