Coating production line

A coating production line and spraying device technology, which is applied to the surface coating liquid device, coating, spraying device, etc., can solve the problems of uneven spraying and different thicknesses of spraying, and achieve the effect of strengthening the fixation, reducing waste and saving resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

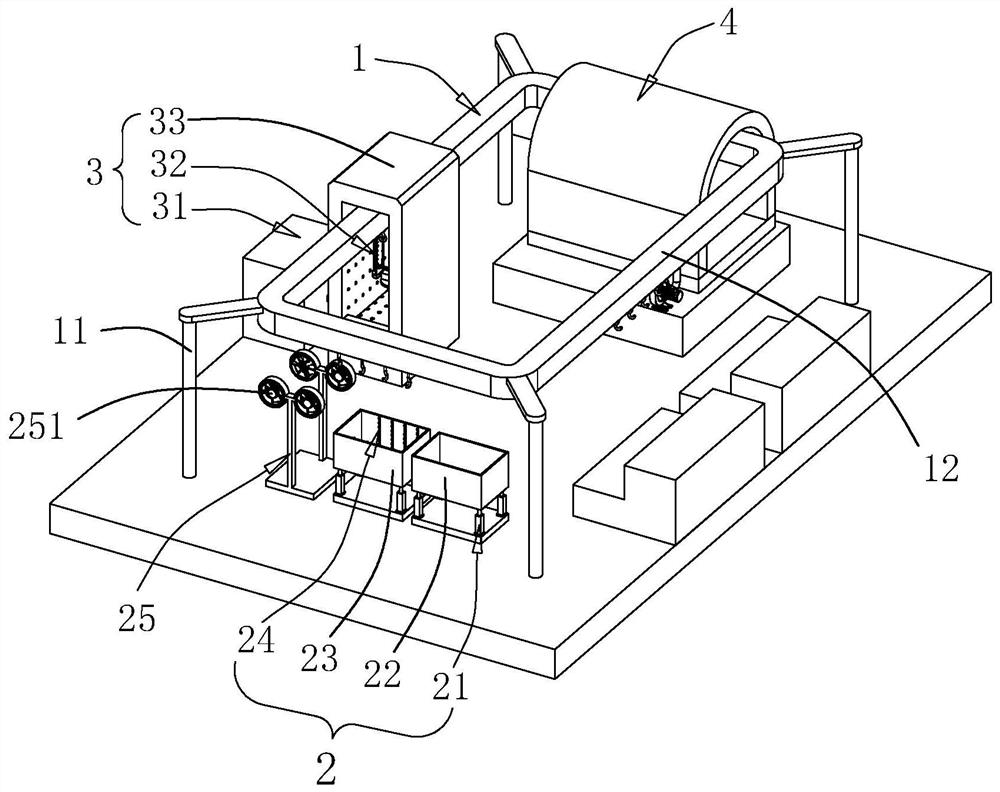

[0038] The following is attached Figure 1-6 The application is described in further detail.

[0039] The embodiment of the present application discloses a coating production line. refer to figure 1 , the coating production line includes a conveying device 1 and a pre-processing device 2, a spraying device 3 and a curing device 4 which are sequentially arranged on the conveying device 1; the pre-processing device 2 can clean the surface of the workpiece, and the curing device 4 can clean the workpiece after spraying The surface is dried and solidified; the spraying device 3 includes a body 33 and a spraying mechanism 31 and a rotating mechanism 32 arranged on the body 33 .

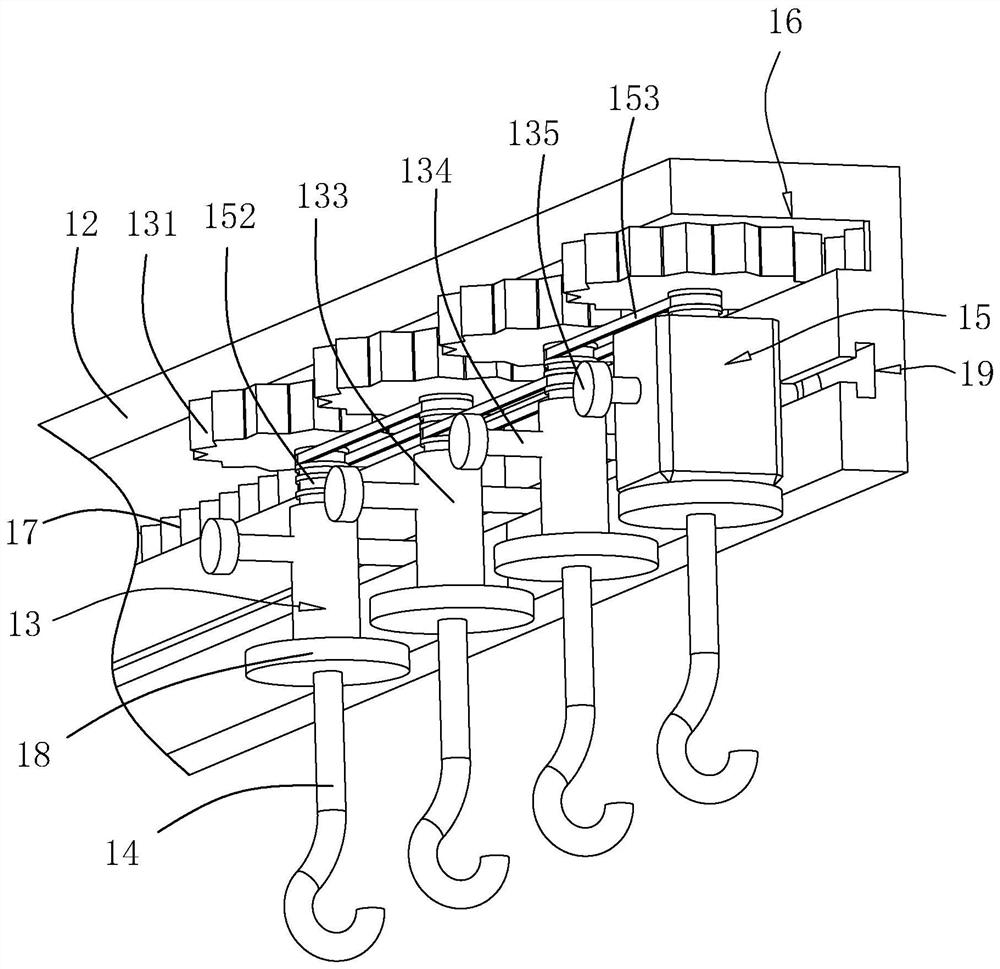

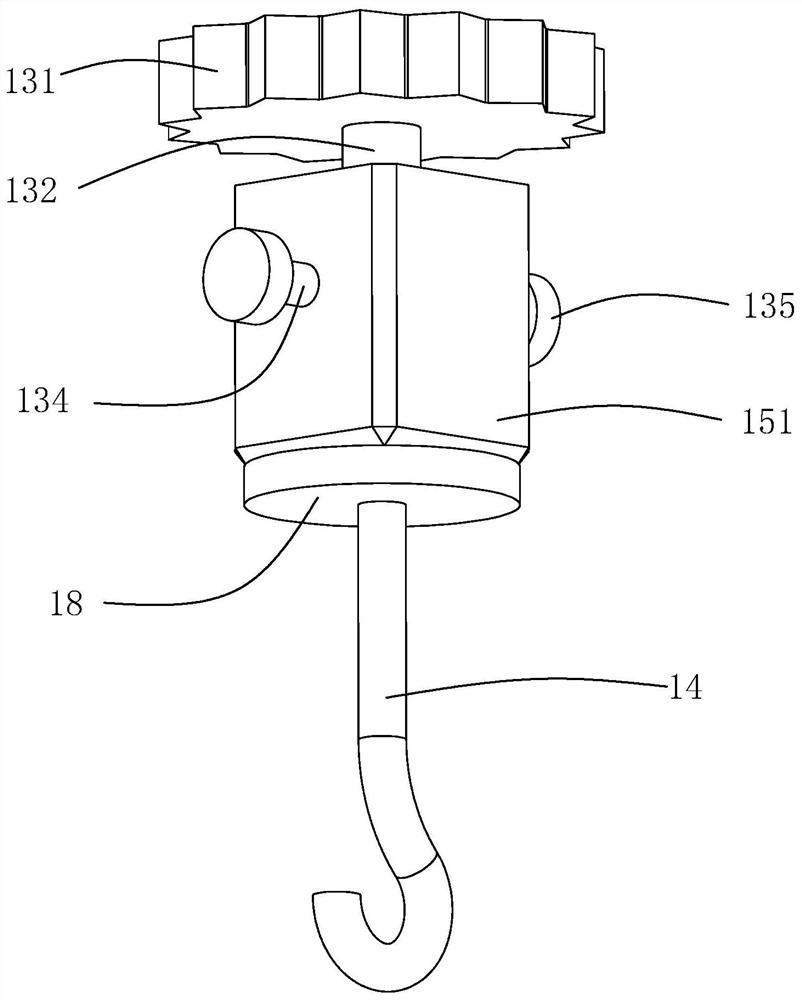

[0040] refer to figure 1 with figure 2 , the conveying device 1 includes a support 11 , a conveying track 12 , a plurality of moving parts 13 , a hanger 14 and a driving mechanism 15 . refer to image 3 , several moving parts 13 are divided into several groups, and moving part 13 comprises transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com