Mold stacking and unstacking device for rice straw decoration plate production

A technology of rice straw and moulds, which is applied in the stacking, unstacking, transportation and packaging of objects, which can solve the problems of easy falling off, potential safety hazards, and low strength, so as to facilitate pushing and taking out and reduce potential safety hazards , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

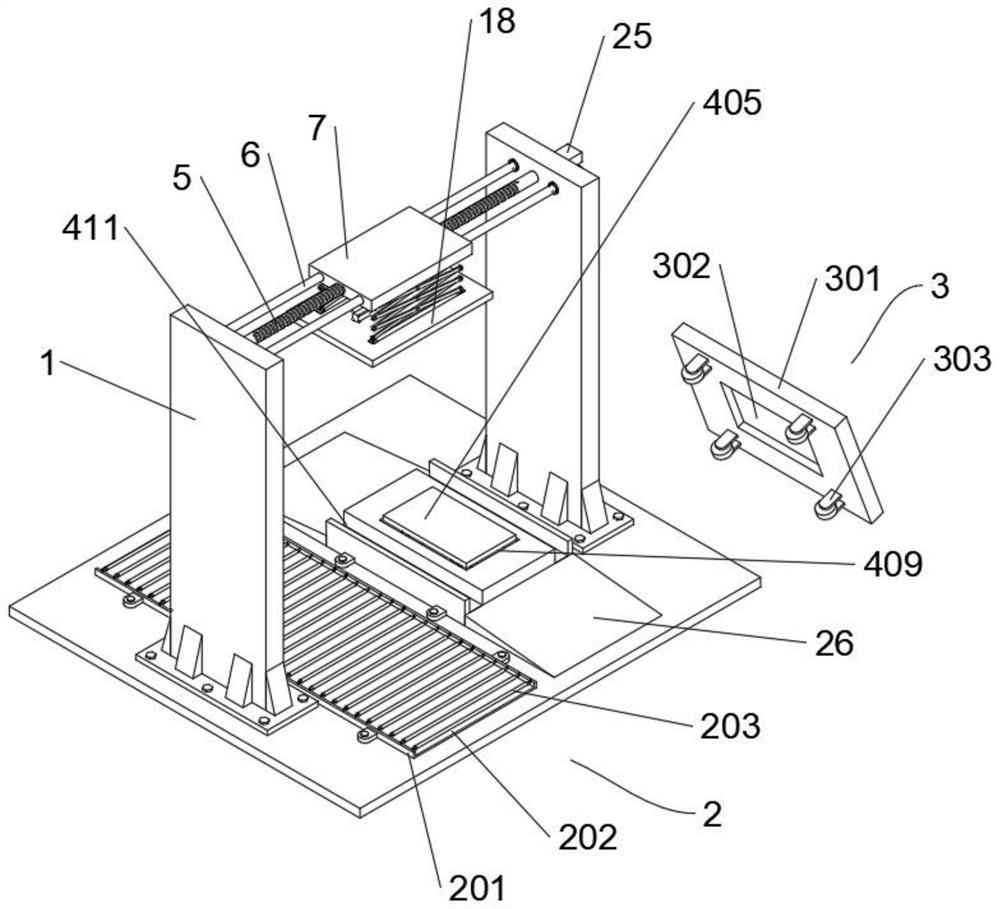

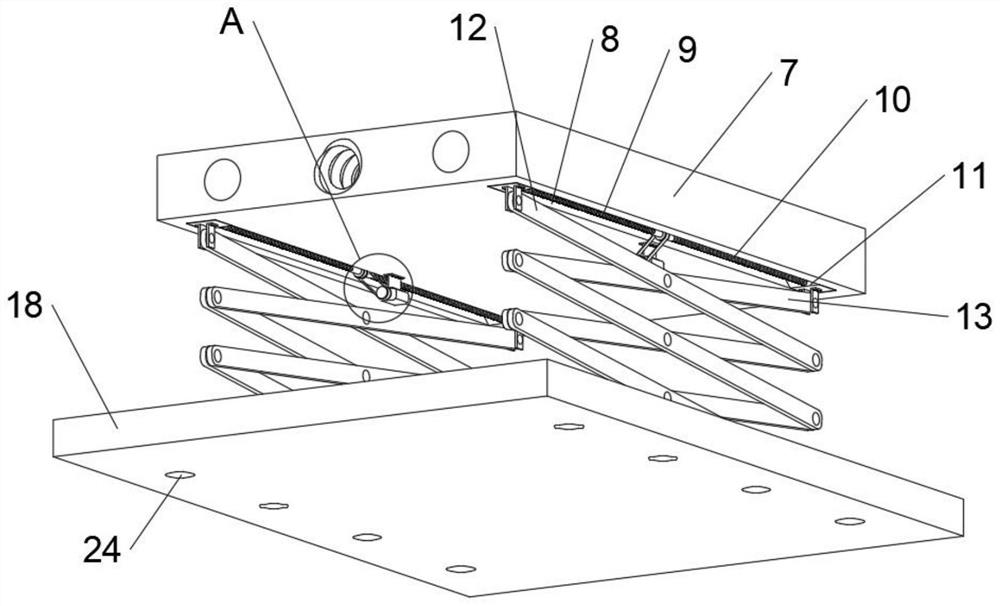

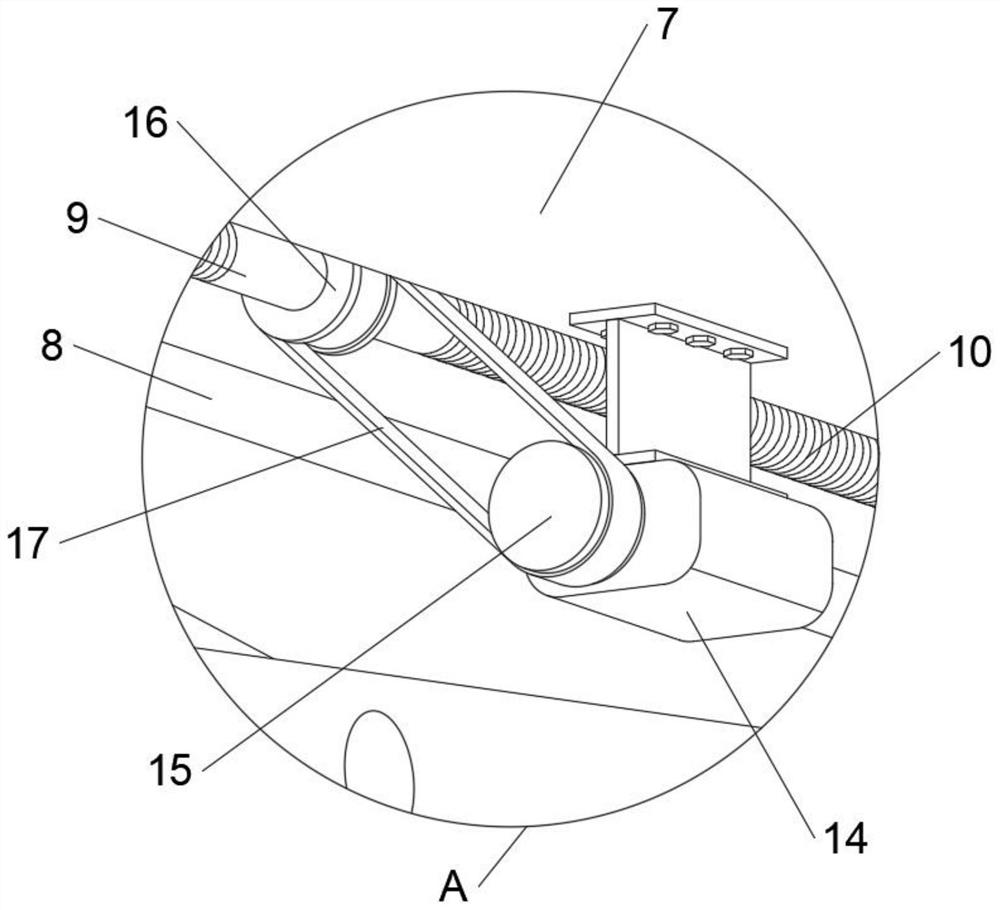

[0029] see Figure 1-6, the present invention provides a technical solution: a mold stacking and unstacking device for the production of rice straw decoration boards, including a push mechanism 2, a limit mechanism 4, a moving component 3 and two support plates 1, and the two support plates 1 are arranged symmetrically , the moving assembly 3 includes a moving plate one 301 , the bottom end of the moving plate one 301 is equipped with rollers 303 , and the bottom end of the moving plate one 301 is provided with a limiting groove 302 . The limiter mechanism 4 comprises a limiter 401, and the two sides of the top of the limiter 401 are symmetrically provided with slideways 411, and the limiter 401 is provided with a cavity 410, and the center of the top wall of the cavity 410 is provided with an opening 409, The inner wall of the cavity 410 is rotationally connected with a rotating shaft 402 symmetrically, and the inner wall of the cavity 410 is rotationally connected with two w...

Embodiment 2

[0034] On the basis of Embodiment 1, the push mechanism 2 includes a push plate 201, the top of the push plate 201 is provided with a through groove 202, and the inner wall of the through groove 202 is rotatably connected with a plurality of guide rollers 203, and the top ends of the guide rollers 203 protrude from the through groove 202.

[0035] Mold is placed on the top of guide roller 203, then, push mold to the lower position of suction plate 18, similarly, the mold after destacking also can be extracted from guide roller 203, is convenient to the pushing and moving out of mold.

[0036] The electrical components appearing in this application are all connected with the external main controller and 220V mains electricity, and the main controller can be a conventional known device such as a computer that plays a control role.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap