Electric heating methanol reformer

A reformer and electric heating technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as large volume, complex structure, and small specific heat of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

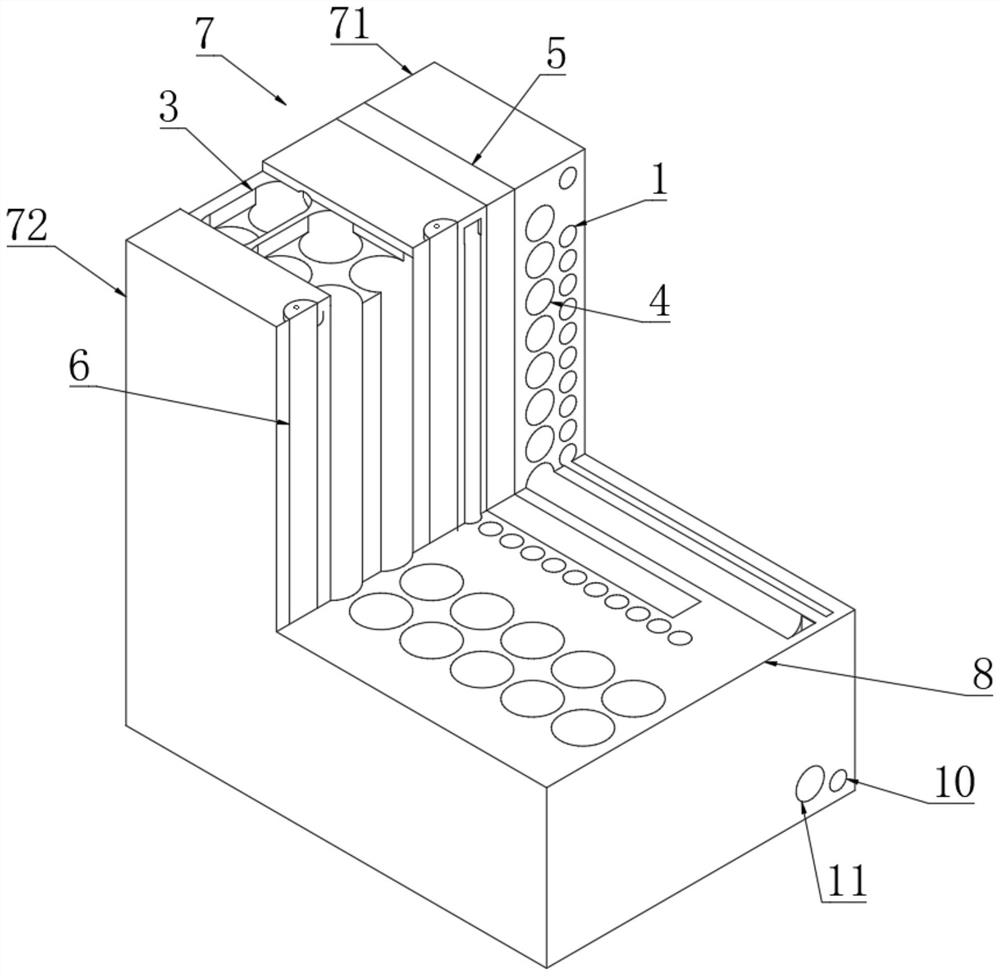

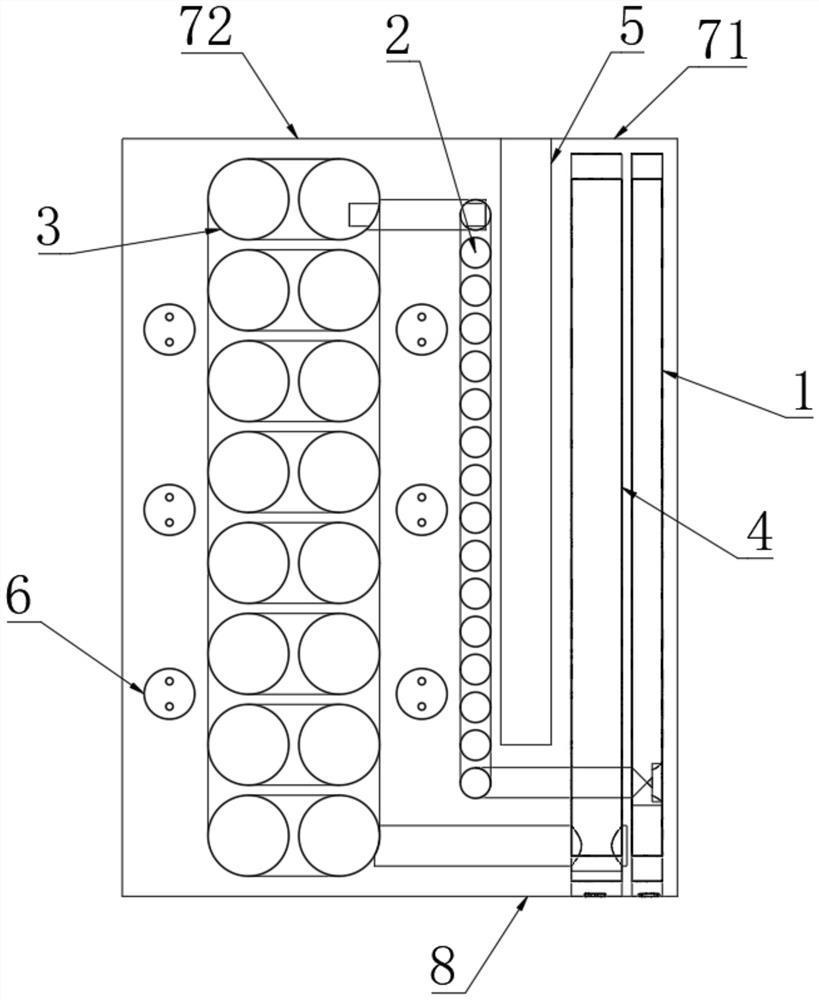

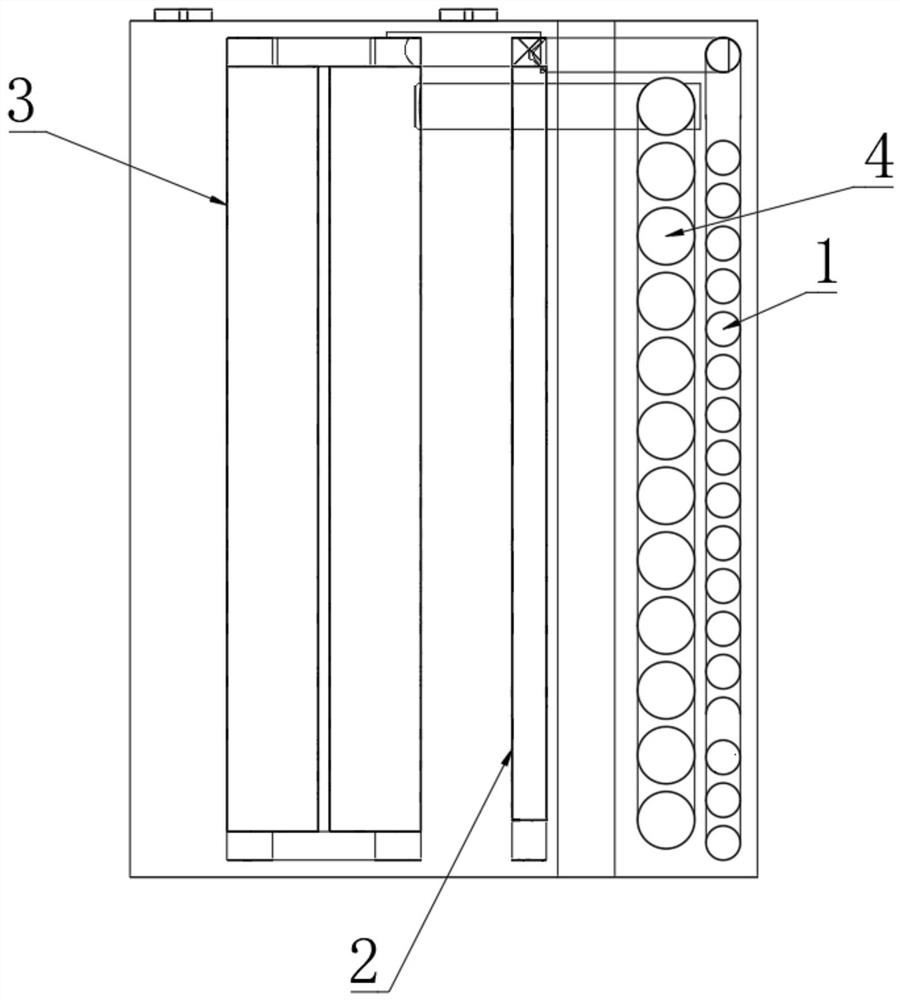

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0028] see Figure 1-4 An electrically heated methanol reformer of the present invention includes a reformer body 7. In this specific embodiment, the reformer body 1 is a cubic structure, and the reformer body 7 has a raw material heat exchange area and a raw material preheating area. , electric heating area, reforming area, recombined gas discharge circuit and heat insulation area;

[0029] The tail end of the raw material heat exchange zone is connected to the head end of the raw material preheating zone, the tail end of the raw material preheating zone is connected to the head end of the reforming zone, and the tail end of the reforming zone is connected to the head end of the recombined gas discharge circuit Connectivity settings;

[0030] The electric heating zone is set corresponding to the reforming zone and raw material preheating zon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com