Method for preparing anisotropic hydrogel

An anisotropic and hydrogel technology, applied in the field of 3D printing and biomaterials, can solve problems that do not conform to the structural composition characteristics of organisms, achieve high precision and simplify the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0085] Dissolve pigskin gelatin (G1890) in phosphate buffer solution to prepare gelatin solutions with a concentration of 80g / L, 100g / L, 120g / L and 140g / L, and use a rheometer to test its temperature change curve to determine the printing temperature.

[0086] Figure 4 The storage modulus and loss modulus of 80g / L, 100g / L, 120g / L and 140g / L gelatin solutions are shown as a function of temperature. From the intersection of the storage modulus curve and the loss modulus curve, the gel temperatures of 80g / L, 100g / L, 120g / L and 140g / L hydrogels were 24°C, 26°C, 26.5°C and 28°C respectively. °C to determine the printing temperature of each gelatin solution.

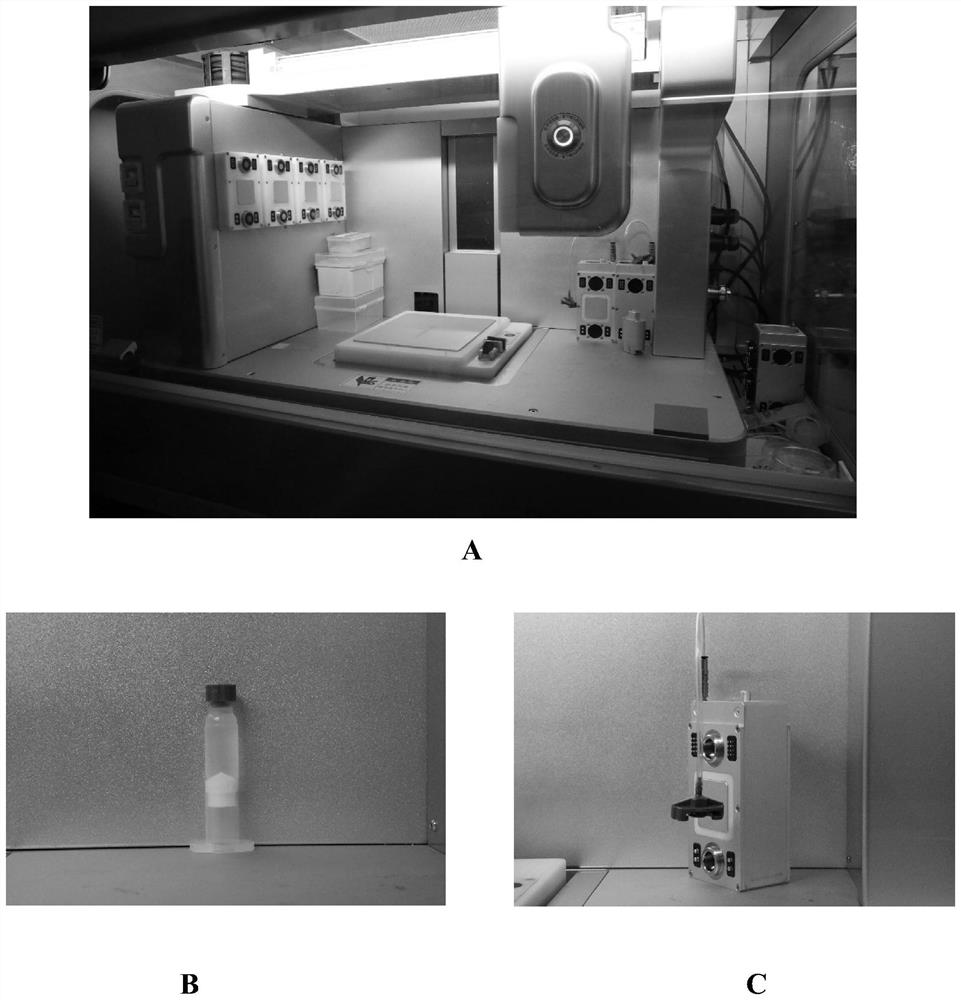

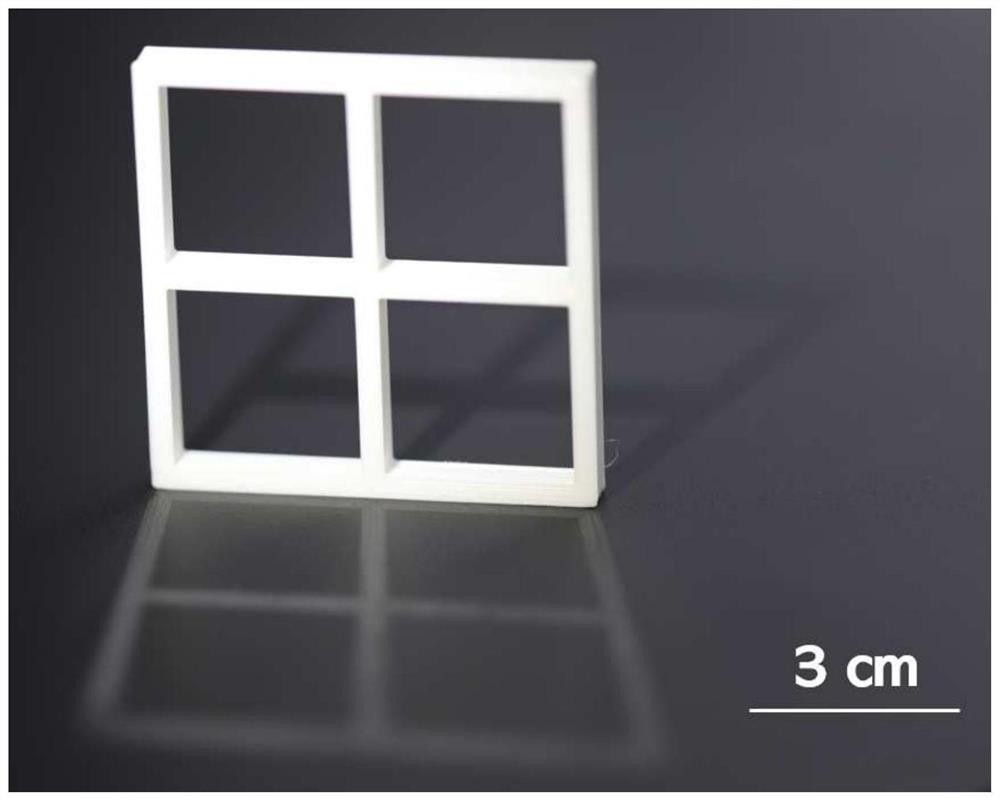

[0087] Using commercially available PLA filaments that can be used for 3D printing as raw materials, a 3D printer was used to print the mold. The specifications of the PLA wire are as follows: diameter 2.85±0.10mm, maximum roundness deviation 0.10mm, wire net weight 350g / 750g, wire length ~44m / ~95m.

Embodiment 1

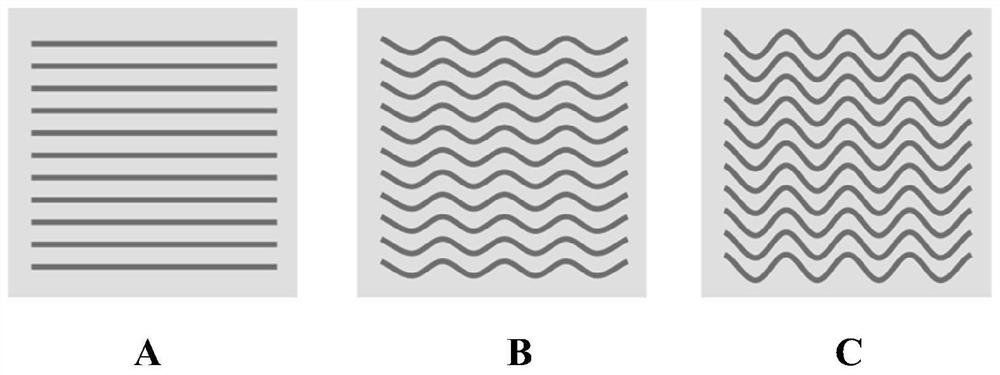

[0089] Add the gelatin solution with a concentration of 80g / L into the barrel of the 3D printer. The temperature of the 3D printer platform is controlled at 10°C, the temperature of the nozzle is controlled at 24°C, the printing pressure is set to 0.12MPa, and the printing speed is set to 30mm / s. Default patterns such as image 3 As shown in A, the wire spacing is set to 1mm, and the number of printing layers is set to 1 layer. After the printed 80g / L gelatin solution is solidified, manually add 4.5mL of 100g / L gelatin solution into the mold, and add 15mM 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide 600 μL of aqueous solution of N-hydroxysuccinimide and 600 μL of 6 mM N-hydroxysuccinimide aqueous solution were cross-linked at 4 ° C for one hour in the dark, and then washed with phosphate buffer for 3 times for 15 min each time to obtain a hydrogel glue.

[0090] The mechanical properties of the hydrogel obtained in this embodiment were tested using a tensile tester. The hy...

Embodiment 2

[0092] Add the gelatin solution with a concentration of 80g / L into the barrel of the 3D printer. The temperature of the 3D printer platform is controlled at 10°C, the temperature of the nozzle is controlled at 24°C, the printing pressure is set to 0.12MPa, and the printing speed is set to 30mm / s. Default patterns such as image 3 As shown in B, the wire spacing is set to 1mm, the period is set to 2mm, the amplitude is set to 1mm, and the number of printing layers is set to 1 layer. After the printed 80g / L gelatin solution is solidified, manually add 4.5mL of 100g / L gelatin solution into the mold, and add 15mM 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide 600 μL of aqueous solution of N-hydroxysuccinimide and 600 μL of 6 mM N-hydroxysuccinimide aqueous solution were cross-linked at 4 ° C for one hour in the dark, and the cross-linking agent was washed away with phosphate buffer, 15 min / time, and washed 3 times in total to obtain a hydrogel .

[0093] The mechanical properties...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture stress | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| Fracture stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com