Soluble ball seat capable of increasing dissolving speed

A technology of dissolution rate and ball seat, applied in the fields of production fluids, wellbore/well components, earthwork drilling, etc., can solve the problems of slow dissolution rate, large rubber length and volume, etc., to prevent loss, reduce metal volume, Volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

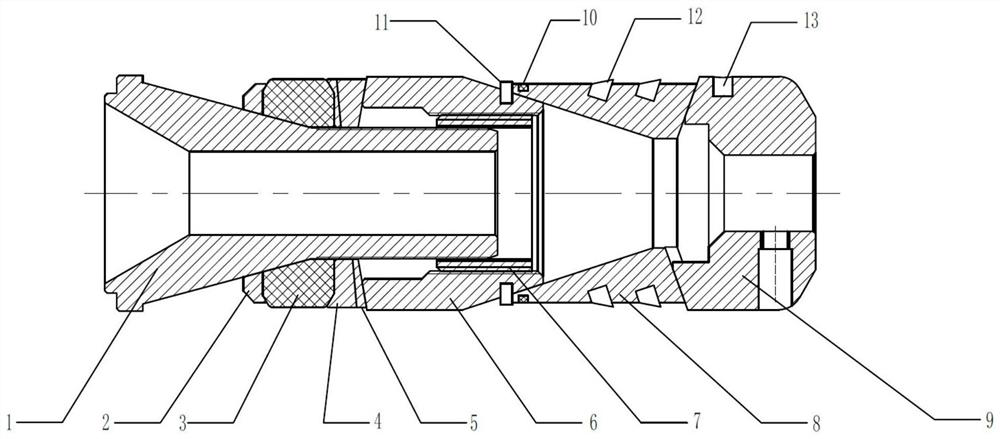

[0032] refer to figure 1 , 5 and 6, the present embodiment provides a dissolvable ball seat that improves the dissolution rate, including a central tube 1, a cone 6, a slip body 8 and an anti-collision ring 9 that are sequentially connected from top to bottom, and the external center tube 1 The thread is connected with the inner thread of the lock ring 7, and the inner thread of the cone 6 is connected with the outer thread of the lock ring 7; the central tube 1 has an outer tapered surface, and the central tube 1 is sequentially provided with the upper wrist guard 2, sealing Rubber 3, lower wrist guard 4 and support seat 5, slip teeth 12 are installed circumferentially on the slip body 8, and the slip teeth 12 are helical teeth, and the tip of the slip teeth 12 faces below the ball seat when assembled.

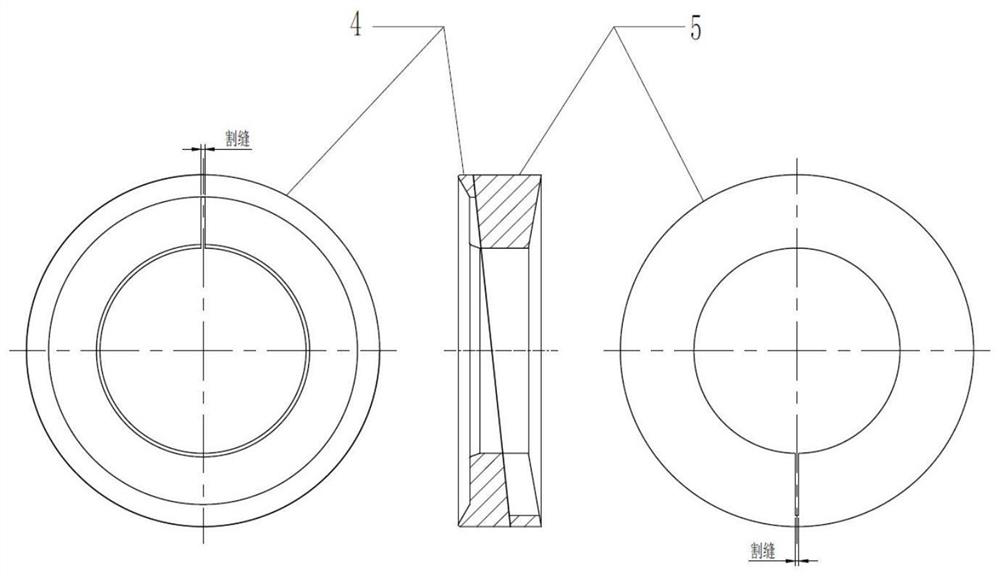

[0033] The lower wrist guard 4 and the support seat 5 are fitted on an inclined plane. At the same time, the lower wrist guard 4 and the support seat 5 are respectively slit...

Embodiment 2

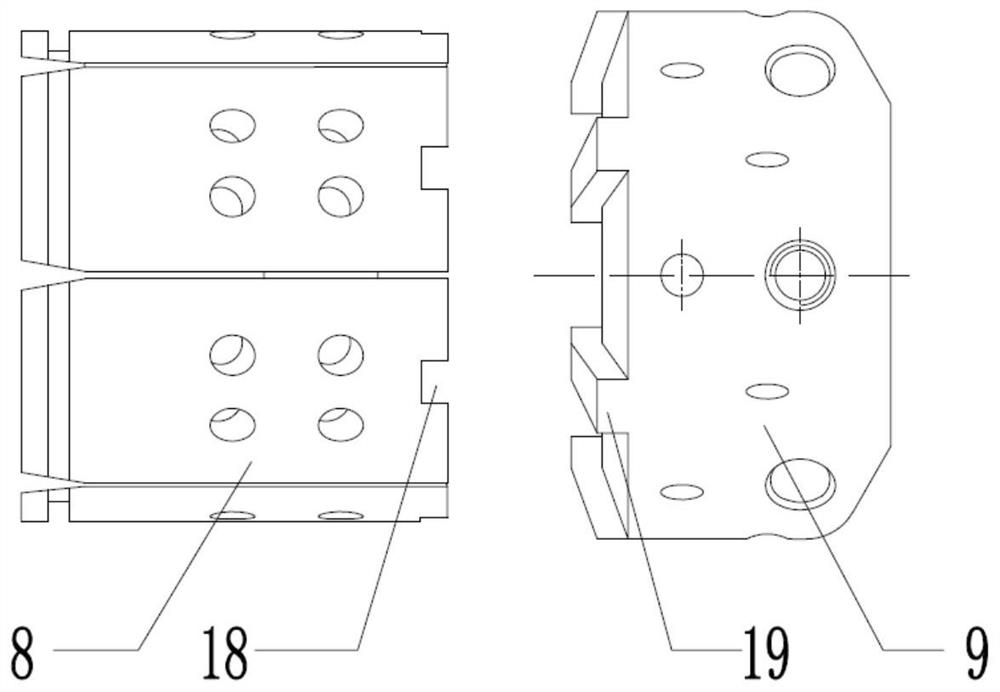

[0038] This embodiment is further preferred on the basis of Embodiment 1, refer to figure 1 , 3 And 4, the inner tapered surface of the slip body 8 cooperates with the outer tapered surface of the cone 6, and the split pin 11 is evenly installed on the cone 6, and the split pin 11 is opened with the upper end of the slip body 8 The lower end of the slip body 8 is evenly provided with split grooves 18 in the circumferential direction, and cooperates with the split protrusions 19 provided on the upper end of the anti-collision ring 9 .

[0039]In the present invention, by adding the split pin 11 and the split protrusion 19, during the ball seat setting process, the effective split of the slips can be ensured, and the slip body 8 can be evenly opened along the slit, avoiding jamming. The tile body 8 prevents the "C shape" from opening, which can greatly improve the anchoring ability of the slips.

Embodiment 3

[0041] This embodiment is further preferred on the basis of Embodiment 1, refer to figure 1 , The upper part of the slip body 8 is provided with an annular groove in the circumferential direction, and a rectangular ring 10 is arranged in the annular groove, and the rectangular ring 10 is made of soluble rubber material.

[0042] After the ball seat is set, the slips partly crawl along the slope of the cone 6 to the inner wall of the anchor sleeve, and the resilience of the rectangular ring 10 itself provides a pullback force for the slips, which cooperates with the cone 6 to form a triangular force relationship, which promotes The slip body 8 fits the inner wall of the casing, which can solve the problem of slip fall in a single slip structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com