Processing method of normal-temperature storage type whole-grain instant noodles

A technology of normal temperature storage and processing method, applied in the field of pasta processing, can solve the problems of high transportation and storage cost, poor taste, restricted development, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

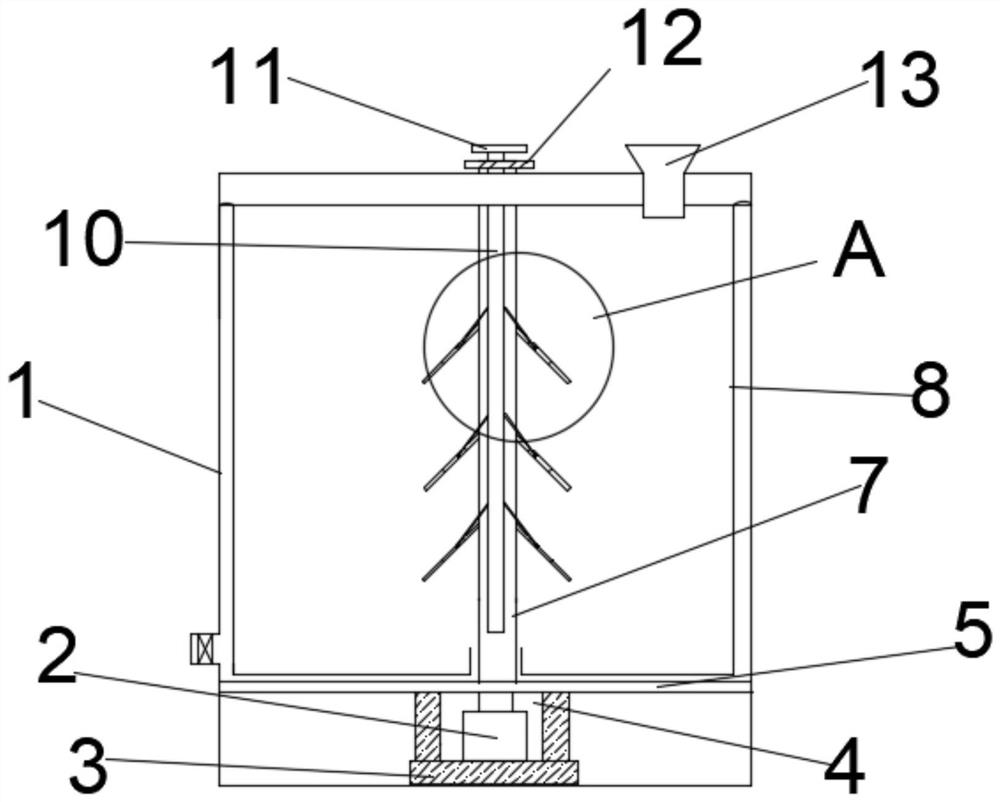

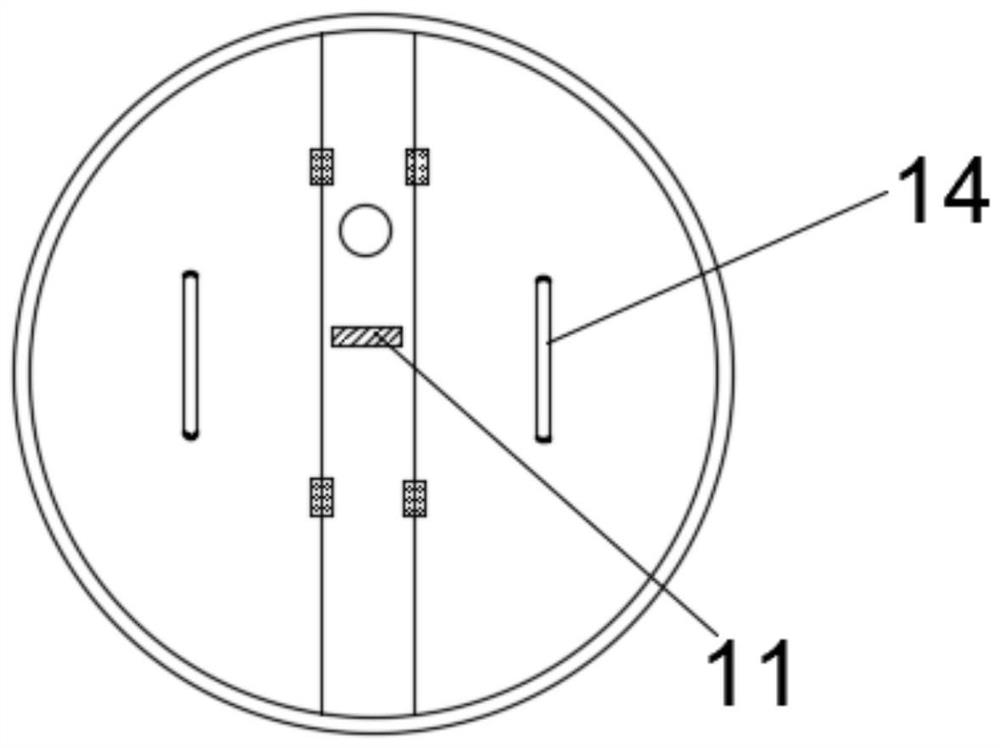

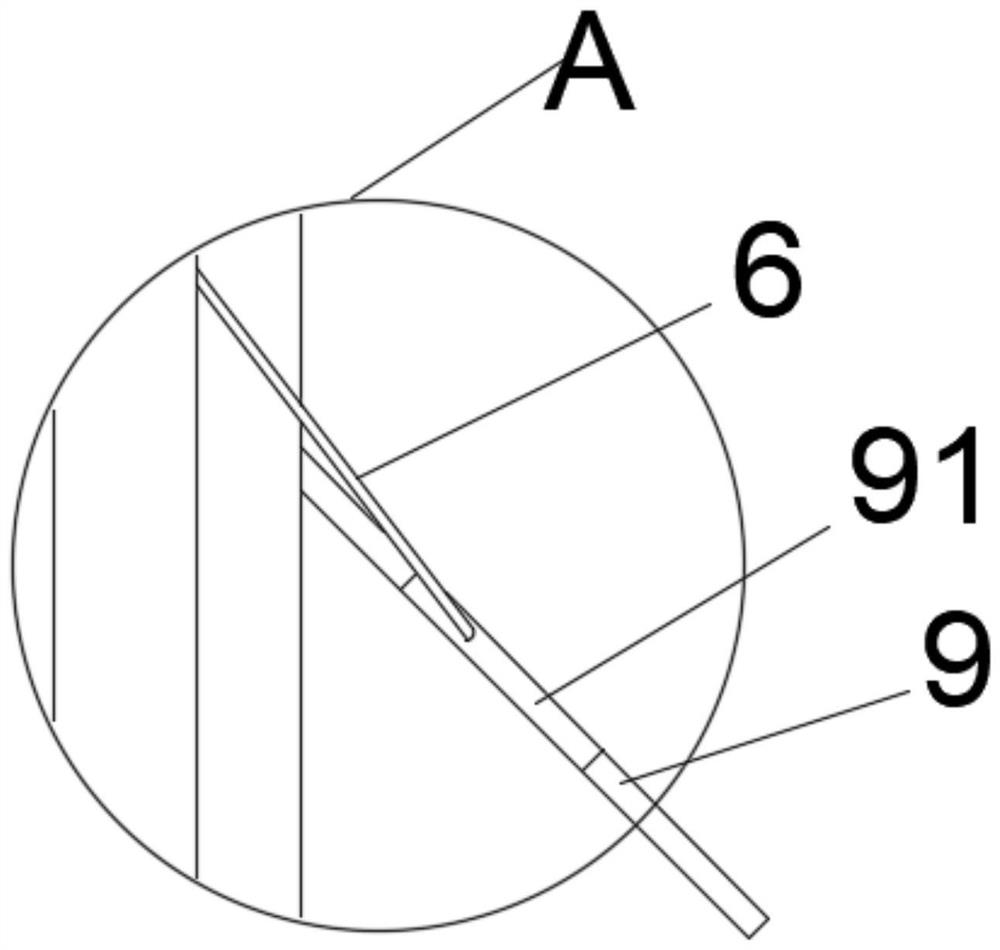

Image

Examples

Embodiment 1

[0035] A method for processing instant noodles with whole grains stored at normal temperature, comprising the following steps:

[0036] Step 1: Grinding: Add 80 parts by weight of buckwheat, 10 parts by weight of corn, 20 parts by weight of red beans, 20 parts by weight of mung beans, and 20 parts by weight of millet into a pulverizer to pulverize them into powder, and then mix them into miscellaneous grain powder;

[0037] Step 2: Kneading and processing: add the multigrain powder obtained in step 1, 2% salt by weight, 50% water, and 3% baking soda by weight into the mixer, and mix the powder with the mixer for 240 seconds, then pour Put it into the washbasin, seal it with plastic wrap and proof for 30 minutes to make the miscellaneous grain noodle dough, roll it into several miscellaneous grain noodle cakes with a noodle rolling machine, then put the miscellaneous grain noodle cake into the extruder, and process it into miscellaneous grain noodles;

[0038] Step 3: Noodle pr...

Embodiment 2

[0042] A method for processing instant noodles with whole grains stored at normal temperature, comprising the following steps:

[0043] Step 1: Grinding: Add 90 parts by weight of buckwheat, 30 parts by weight of corn, 30 parts by weight of red beans, 30 parts by weight of mung beans, and 30 parts by weight of millet into a pulverizer to pulverize them into powder, and then mix them into miscellaneous grain powder;

[0044] Step 2: Kneading and processing: add the multigrain powder obtained in step 1, 2% salt by weight, 50% water, and 3% baking soda by weight into the mixer, and mix the powder with the mixer for 240 seconds, then pour Put it into the washbasin, seal it with plastic wrap and proof for 30 minutes to make the miscellaneous grain noodle dough, roll it into several miscellaneous grain noodle cakes with a noodle rolling machine, then put the miscellaneous grain noodle cake into the extruder, and process it into miscellaneous grain noodles;

[0045] Step 3: Noodle pr...

Embodiment 3

[0049] A method for processing instant noodles with whole grains stored at normal temperature, comprising the following steps:

[0050] Step 1: Pulverizing: 100 parts by weight of buckwheat, 30 parts by weight of corn, 40 parts by weight of red beans, 40 parts by weight of mung beans, and 40 parts by weight are respectively added to a pulverizer to pulverize into powder, and then mixed into miscellaneous grain powder;

[0051] Step 2: Kneading and processing: add the multigrain powder obtained in step 1, 2% salt by weight, 50% water, and 3% baking soda by weight into the mixer, and mix the powder with the mixer for 240 seconds, then pour Put it into the washbasin, seal it with plastic wrap and proof for 30 minutes to make the miscellaneous grain noodle dough, roll it into several miscellaneous grain noodle cakes with a noodle rolling machine, then put the miscellaneous grain noodle cake into the extruder, and process it into miscellaneous grain noodles;

[0052] Step 3: Noodle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com